Magnetic composite plate, manufacturing method of magnetic composite plate and magnetic bulletin board made by composite plate

A composite board and notice board technology, which is applied in chemical instruments and methods, display devices, wood-layered products, etc., can solve the problems of difficulty in pinning, reducing the service life of composite boards, and complicated manufacturing processes, and achieves easy pinning, Easy-to-use, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

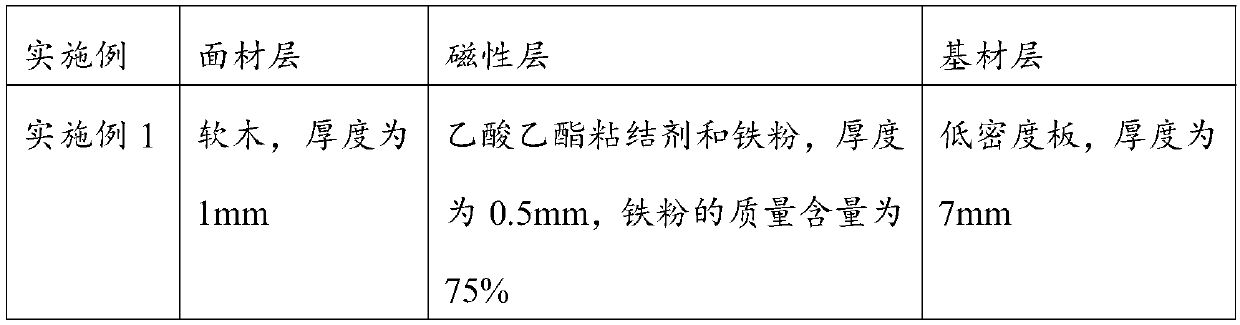

[0044] A magnetic composite board includes a surface material layer 1, a magnetic layer 2 and a base material layer 3 arranged in sequence. The material and composition of each layer are shown in Table 1:

[0045] Table 1

[0046]

[0047]

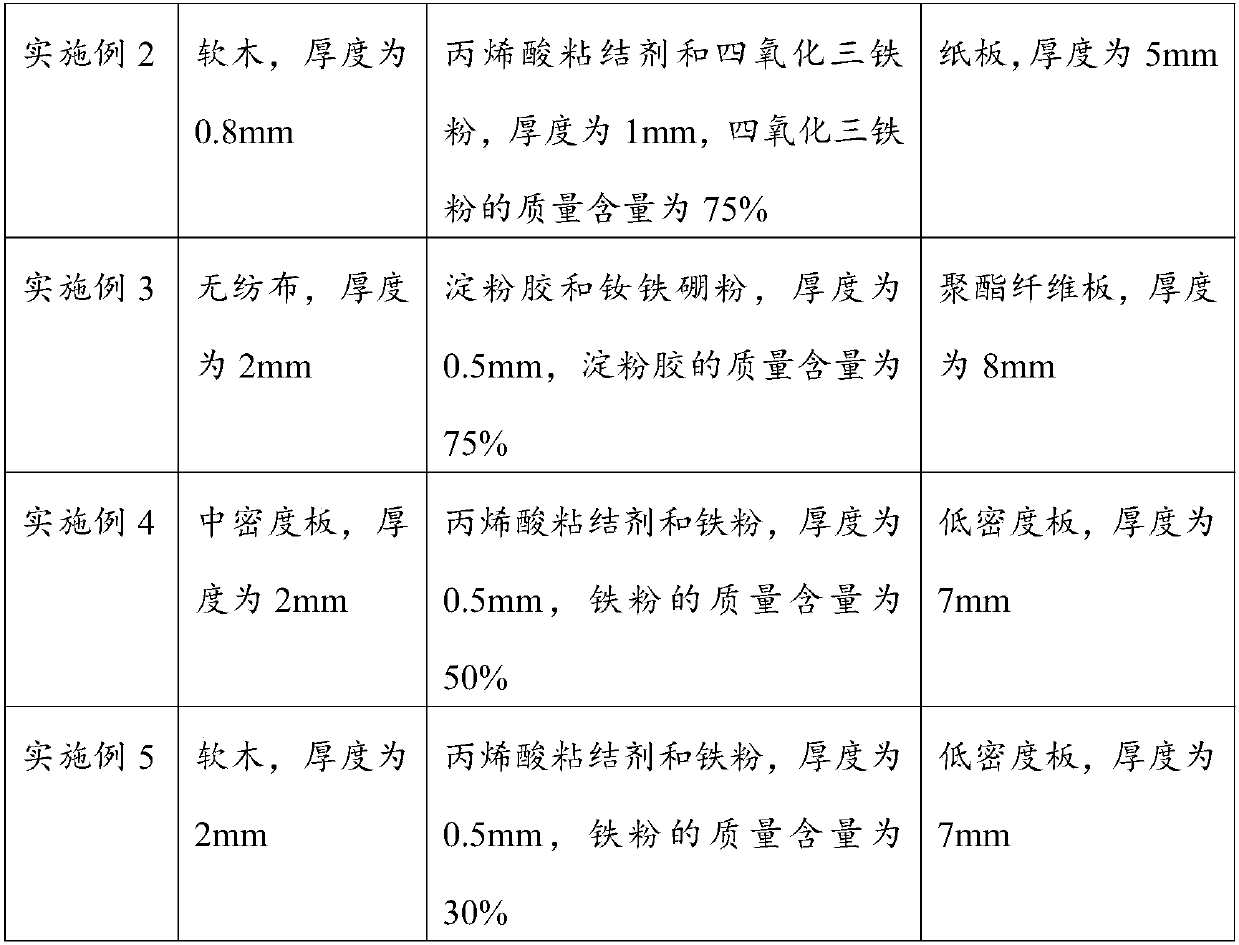

[0048] Using H-shaped nails with a nail length of 8 mm and common commercially available strong magnetic nails (the magnetic material is NdFeB), a postcard with a weight of 5 g was fixed on the surface of the magnetic composite board prepared in Examples 1-5. See Table 2 for the difficulty of inserting the I-shaped nails into the composite board and the degree of fixation of the magnetic nails.

[0049] Table 2

[0050]

[0051] It can be seen from Table 2 that for the magnetic composite boards of Examples 1 to 3, postcards can be fixed using H-shaped nails and magnetic nails. If the surface material layer is replaced by a medium density board with higher hardness, or the content of magnetizable material in the magnetic layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com