Glass product sub-packaging mechanism

A technology for glass products and sub-packaging, which is used in classification, solid separation, chemical instruments and methods, etc., to achieve the effect of strong practicability and reduced labor operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

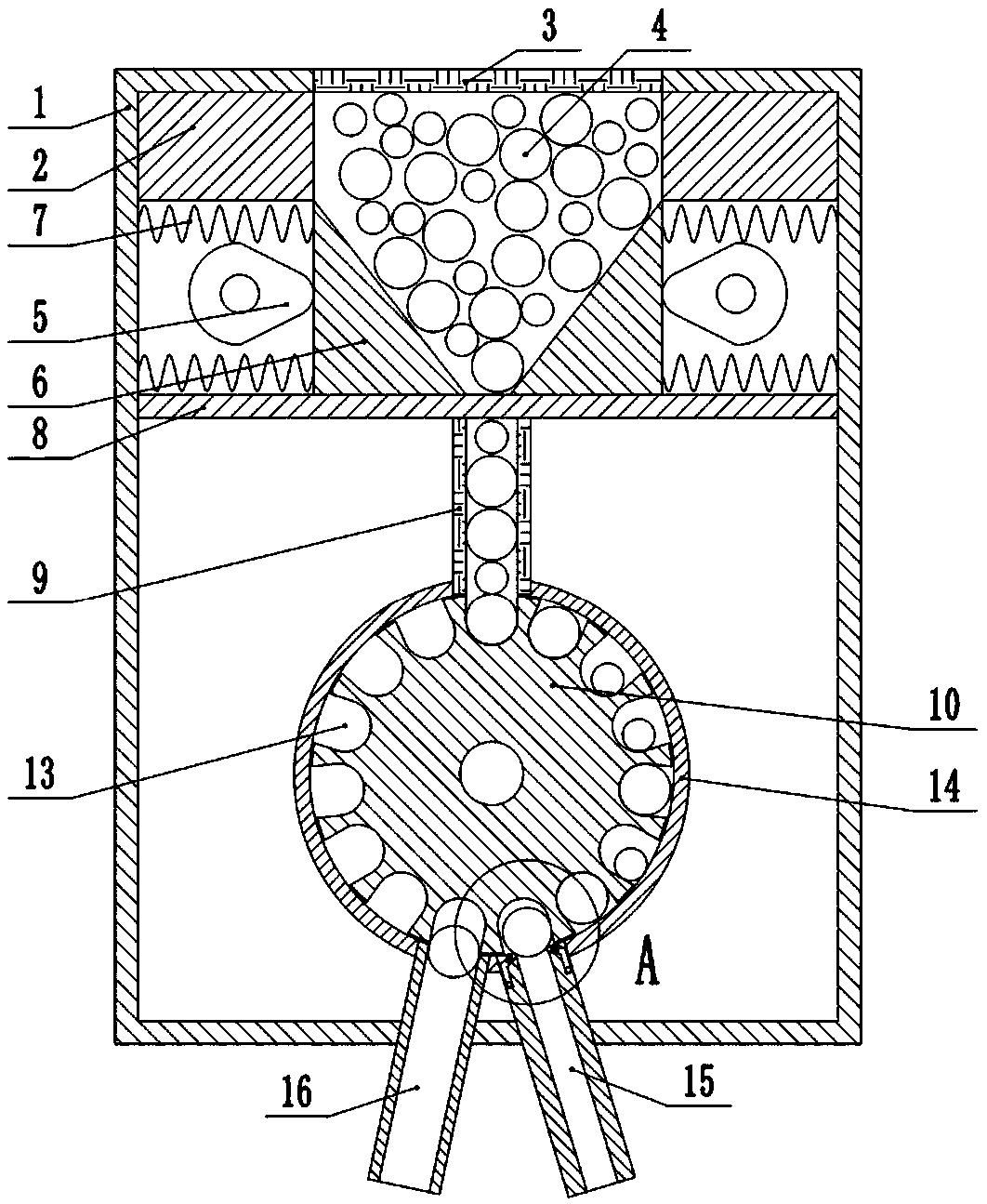

[0039] Glass product packaging mechanism, basically such as figure 1 As shown, a screening cylinder 1 is included, and the screening cylinder 1 is in the shape of a cuboid. Both sides of the top of the screening cylinder 1 are fixed with baffles 2, and the top of the screening cylinder 1 between the two baffles 2 is equipped with a conveyor belt 3 on which glass products of different sizes are conveyed. 4.

[0040] A vibrating part is installed under the baffle plate 2, and the vibrating part includes a disc cam 5 and a wedge plate 6 located below the baffle plate 2. A disc cam 5 and a wedge plate 6 are respectively installed under the two baffle plates 2, and the disc-shaped The cam 5 is rotatably connected to the screening cylinder 1 through the second connecting rod 22, the disc cam 5 is against the wedge plate 6, the wedge surfaces of the two wedge plates 6 are oppositely arranged, and the section of the wedge plate 6 facing the disc cam 5 is in contact with the screen. Th...

Embodiment 2

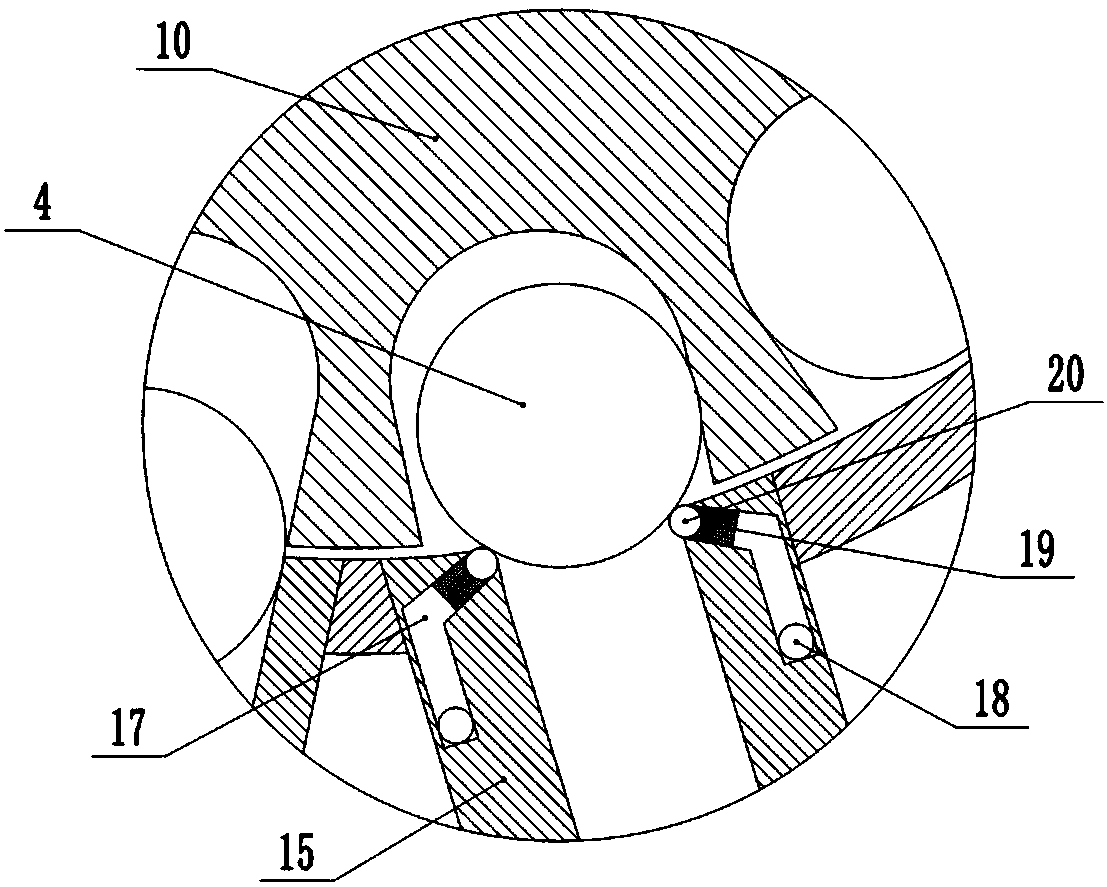

[0051] Glass product packaging mechanism, basically such as image 3 and Figure 4 As shown, compared with Embodiment 1, the end of the first connecting rod 11 away from the rotating disk 10 is fixedly connected with the first gear 21, and the shaft centers of the two disk cams 5 are fixedly connected with the second connecting rod 22, and the two A second gear 23 is fixedly connected to each of the second connecting rods 22, and a third gear 24 is meshed between the first gear 21 and the two second gears 23, and the third gear 24 is rotatably connected to the screen through the third connecting rod 25. On the sub-cylinder 1 , the number of teeth of the third gear 24 is greater than the number of teeth of the first gear 21 and the second gear 23 .

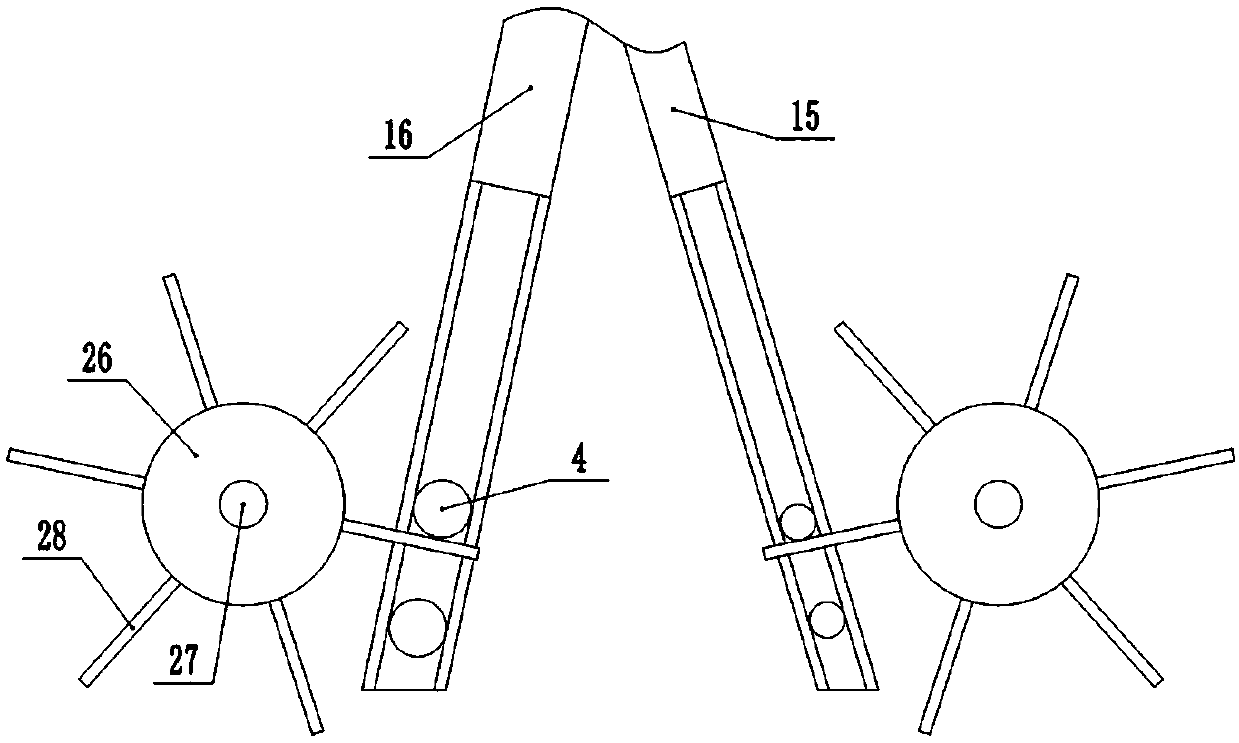

[0052] An open structure is provided at the bottom of the first screening pipeline 15 and the second screening pipeline 16, and an anti-collision mechanism is installed on the open structure. The anti-collision mechanism includes ...

Embodiment 3

[0059] Compared with the second embodiment, the glassware dispensing mechanism has a first magnet fixedly connected to the counterweight 29 and a second magnet fixedly connected to the second groove 12 . The counterweight 29 slides to a suitable position in the second groove 12 , and the counterweight 29 is magnetically attached to the second groove 12 of the receiving plate 28 to be locked by magnetic attraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com