A kind of preparation method of special modified molecular sieve for ceramic ink

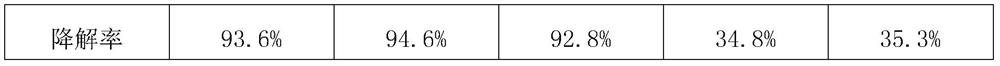

A ceramic ink and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, inks, etc., can solve the problems of no color development, photocatalytic performance needs to be improved, colorant color darkening, etc., to achieve color stability and improve color The effect of vividness and high photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

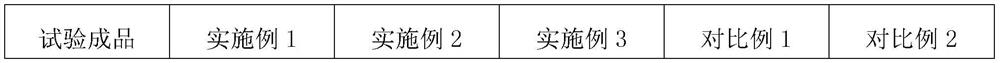

Examples

Embodiment 1

[0025] The preparation method of the special modified molecular sieve for ceramic ink provided by the invention is as follows:

[0026] A preparation method of a special modified molecular sieve for ceramic ink, comprising the following steps:

[0027] (1) Take Ga respectively 2 O 3 Powder and Bi 2 MoO 6 Powder, the two materials are mixed and uniformly mixed by ball milling to obtain mixture A, wherein Ga 2 O 3 and Bi 2 MoO 6 The molar ratio is 1:2;

[0028] (2) The mixture A obtained in the step (1) is placed in the NH 3 in a muffle furnace, and heated at 850 °C for 8 h to obtain GaN-Bi 2 MoO 6 Composite photocatalytic material, in which NH 3 The flow rate is 80mL / min;

[0029] (3) The GaN-Bi obtained in step (2) 2 MoO 6 The composite photocatalytic material and the molecular sieve are mixed in a ratio of 1:2 by weight to obtain a mixture B, wherein the molecular sieve is selected from ZSM-5;

[0030] (4) add grinding aid to the mixture B that step (3) obtains...

Embodiment 2

[0033] The preparation method of the special modified molecular sieve for ceramic ink provided by the invention is as follows:

[0034] A preparation method of a special modified molecular sieve for ceramic ink, comprising the following steps:

[0035] (1) Take Ga respectively 2 O 3 Powder and Bi 2 MoO 6 Powder, the two materials are mixed and uniformly mixed by ball milling to obtain mixture A, wherein Ga 2 O 3 and Bi 2 MoO 6 The molar ratio is 1.5:2.5;

[0036] (2) The mixture A obtained in the step (1) is placed in the NH 3 , and heated at 900 °C for 10 h to obtain GaN-Bi 2 MoO 6 Composite photocatalytic material, in which NH 3 The flow rate is 90mL / min;

[0037] (3) The GaN-Bi obtained in step (2) 2 MoO 6 The composite photocatalytic material and the molecular sieve are mixed in a ratio of 1:4 by weight to obtain a mixture B, wherein the molecular sieve is selected from a mixture of ZSM-5 and beta mixed in any ratio;

[0038](4) adding a grinding aid to the ...

Embodiment 3

[0041] The preparation method of the special modified molecular sieve for ceramic ink provided by the invention is as follows:

[0042] A preparation method of a special modified molecular sieve for ceramic ink, comprising the following steps:

[0043] (1) Take Ga respectively 2 O 3 Powder and Bi 2 MoO 6 Powder, the two materials are mixed and uniformly mixed by ball milling to obtain mixture A, wherein Ga 2 O 3 and Bi 2 MoO 6 The molar ratio is 2:3;

[0044] (2) The mixture A obtained in the step (1) is placed in the NH 3 , and heated at 950 °C for 13 h to obtain a GaN-Bi2MoO6 composite photocatalytic material, in which NH 3 The flow rate is 100mL / min;

[0045] (3) The GaN-Bi obtained in step (2) 2 MoO 6 The composite photocatalytic material and the molecular sieve are mixed in a ratio of 1:6 by weight to obtain a mixture B, wherein the molecular sieve is a mixture of ZSM-5, beta and Y zeolite molecular sieves mixed in any ratio;

[0046] (4) add grinding aid to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com