Explosion-proof type front filter

A pre-filter, explosion-proof technology, applied in the field of filters, can solve the problems affecting the normal use of smart toilets, the filter cavity is broken, easy to freeze and expand, and achieve anti-freezing and explosion-proof, avoid water leakage, The effect of ensuring water purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

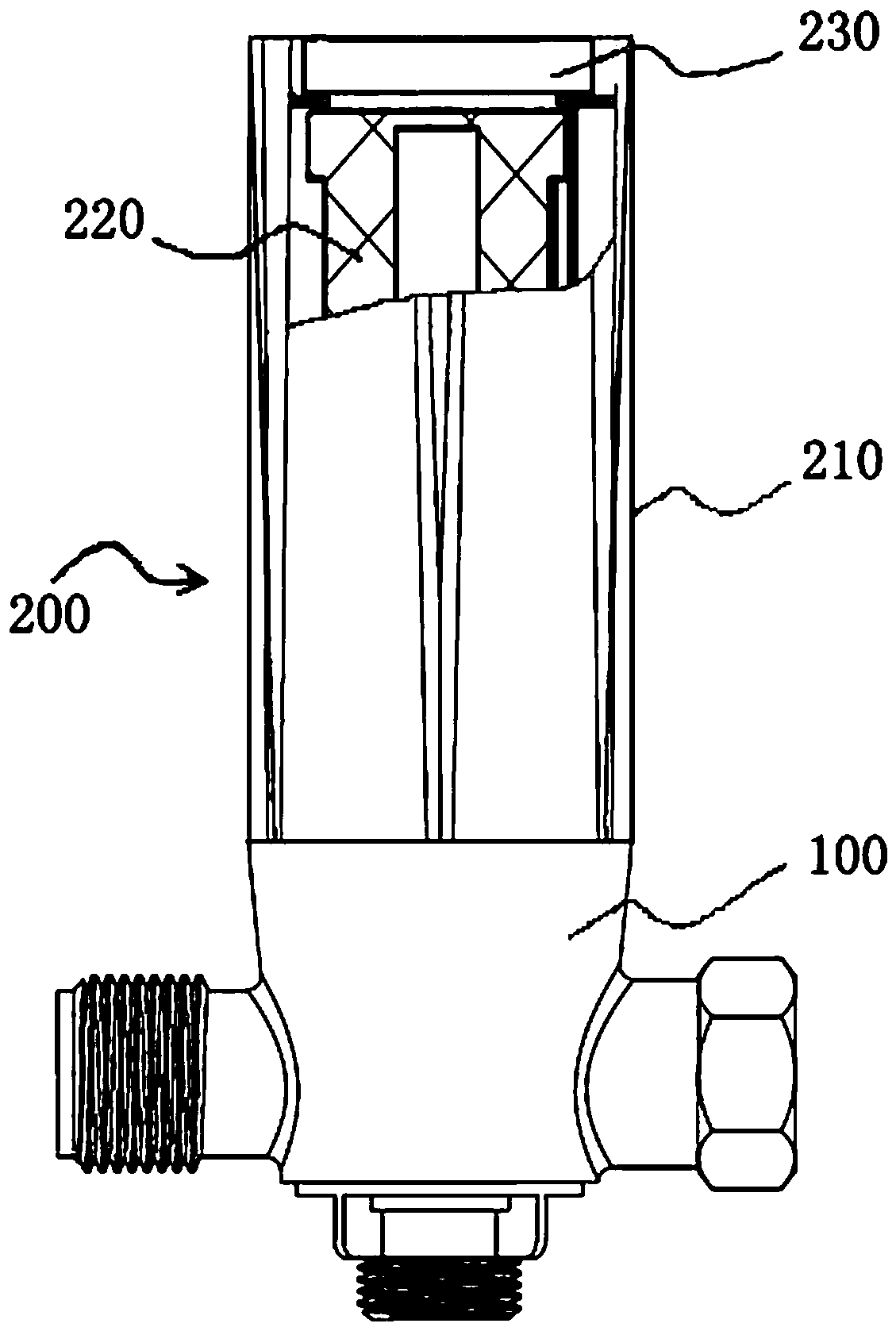

[0033] like figure 1 As shown, this embodiment provides an explosion-proof pre-filter, including a connector 100 and a filter assembly 200 connected to the connector 100, the filter assembly 200 includes an outer shell 210, and The inner filter element 220 and the compressible hollow body 230 arranged in the gap formed between the outer casing 210 and the filter element 220 . The compressible hollow body 230 has a hollow inner cavity, and can be compressed and deformed, and its shape can be diversified, such as spherical, cuboid and other shapes. It should be noted that in this embodiment, the outer surface of the compressible hollow body 230 has no air leakage treatment In order not to reduce the filtration efficiency of the pre-filter of this solution due to the addition of the compressible hollow body 230, the cavity size of the outer casing 210 can be appropriately enlarged according to the volume and contour of the compressible hollow body 230 on the original basis. The ...

Embodiment 2

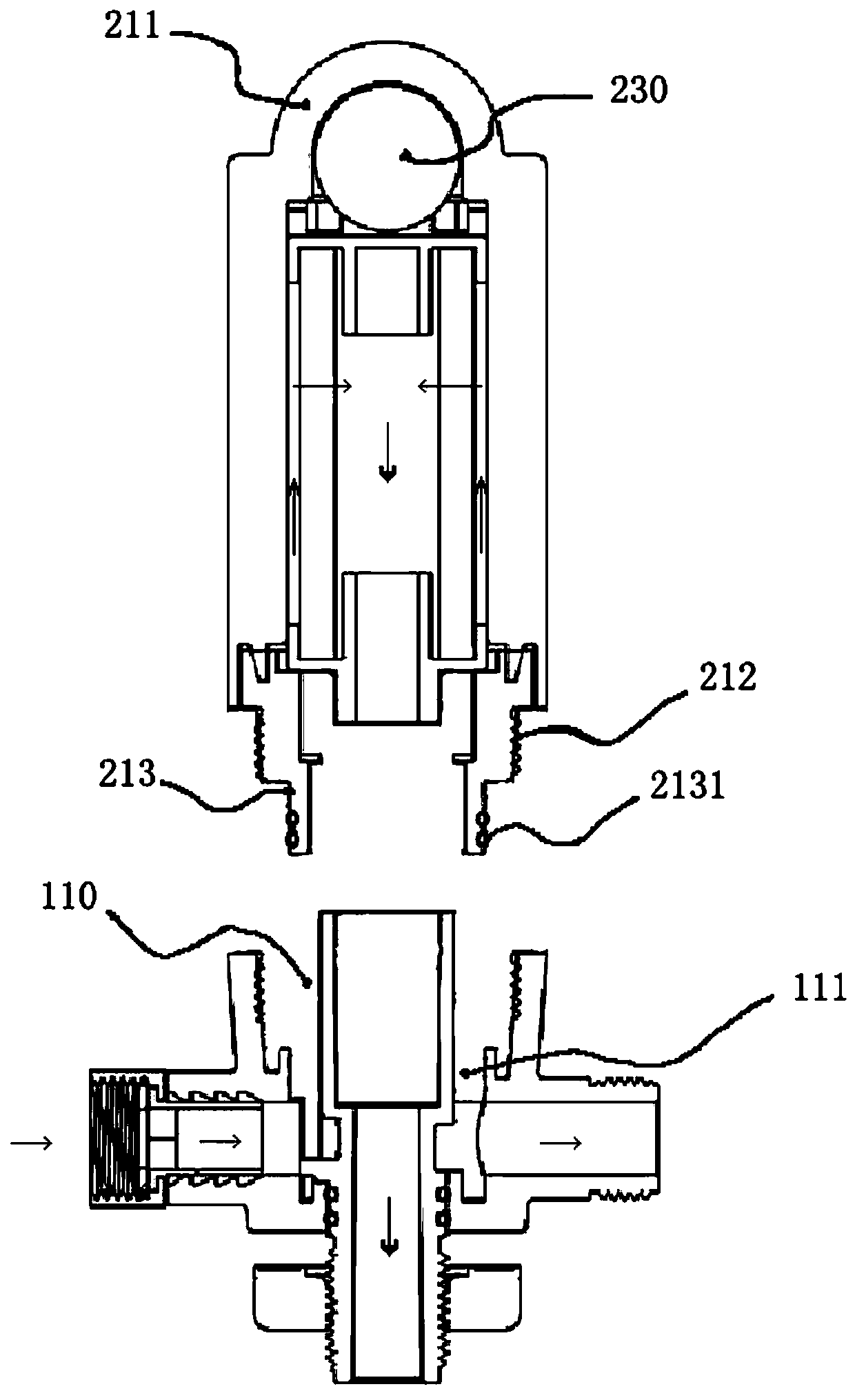

[0037] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the outer casing 210 includes a cylindrical portion and a dome portion 211 integrally formed with the top end of the cylindrical portion, and the compressible hollow body 230 is preferably A hollow ball, the hollow ball is placed in the inner cavity formed by the dome portion 211 , the bottom end of the cylindrical portion is open and connected to the connecting head 100 in a conductive manner.

[0038] Specifically, the connection between the dome portion 211 and the cylindrical portion is provided with a limit hollow ball to prevent it from breaking away from the blocking portion of the inner cavity of the dome portion 211, and the bottom opening of the cylindrical portion can be integrally formed with the connection head 100 and guide In addition, it can also be detachably connected with the connector 100 by screwing as described in the patent document with the notification numbe...

Embodiment 3

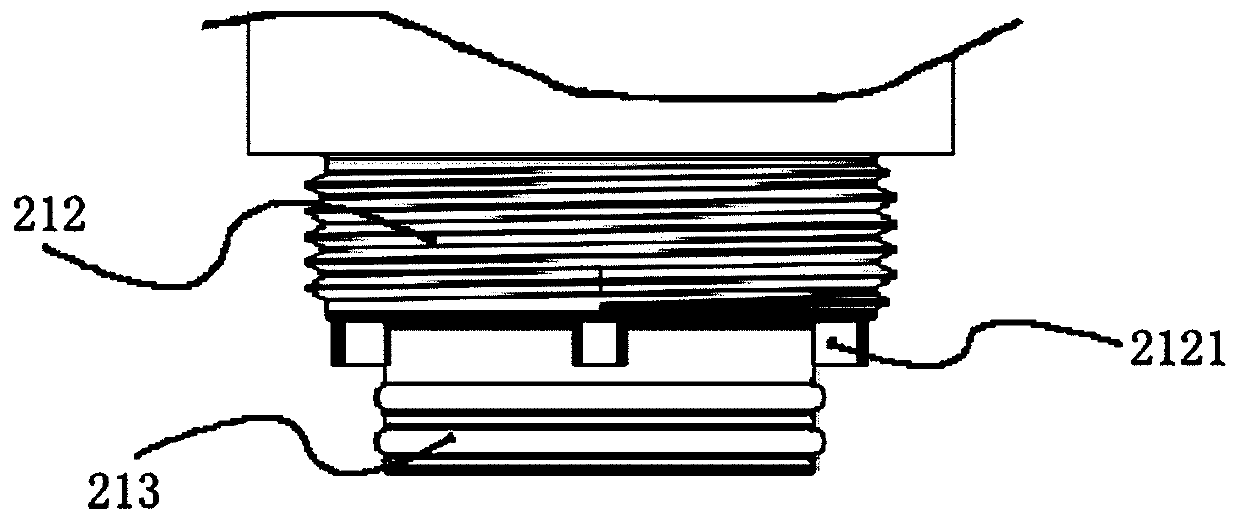

[0044] like Figure 4 As shown, the difference between this embodiment and the previous two embodiments is that a second groove is formed on the outer surface of the water outlet end of the filter element 220 , and a second sealing ring 221 is arranged in the second groove.

[0045] The connector 100 is provided with a water inlet 120, a docking port 110, a first water outlet 130 and a second water outlet 140, and the outer shell 210 is connected to the connector 100 through the docking port 110; the connector 100 is pierced with a drain pipe 150, the water inlet end of the drain pipe 150 is connected to the water outlet end of the filter element 220 through the docking port 110, and the second sealing ring 221 is connected to the inlet end of the drain pipe 150. The inner wall of the water end is close to the inner wall, and the water outlet end of the drain pipe 150 passes through the first water outlet 130 and is detachably connected to the connecting head 100 through a loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com