Perishable vegetable preservation method

A fresh-keeping method and vegetable technology, applied in the fields of fruit and vegetable fresh-keeping, food preservation, food science, etc., can solve the problems of nutrient loss, corn kernel shrinkage, taste decline, etc., and achieve the maintenance of nutritional quality and commodity value, simple operation, The effect of no chemical reagent residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Storage example 1, salt concentration is that 1.5% flowing ice processes sweet corn

[0044] 1. Materials

[0045] The sweet corn comes from Beijing Tianan Agricultural Development Co., Ltd., and it is transported back to the Vegetable Research Center on the same day. The sweet corn that has no mechanical damage, no pests and diseases, and is in good condition is selected as the test material.

[0046] 2. The salt concentration is 1.5% flow ice treatment and storage

[0047] (1) Preparation of pre-cooling medium: adding sodium chloride (NaCl) to water, stirring to make a saline mixture with a salt concentration of 1.5%, cooling the prepared saline mixture to a certain temperature, and crystallizing water from the solution, Thereby forming fine spherical ice crystals (the diameter of the ice crystals is 0.2-0.8mm) to obtain flowable ice, which is the required pre-cooling medium and ready for use.

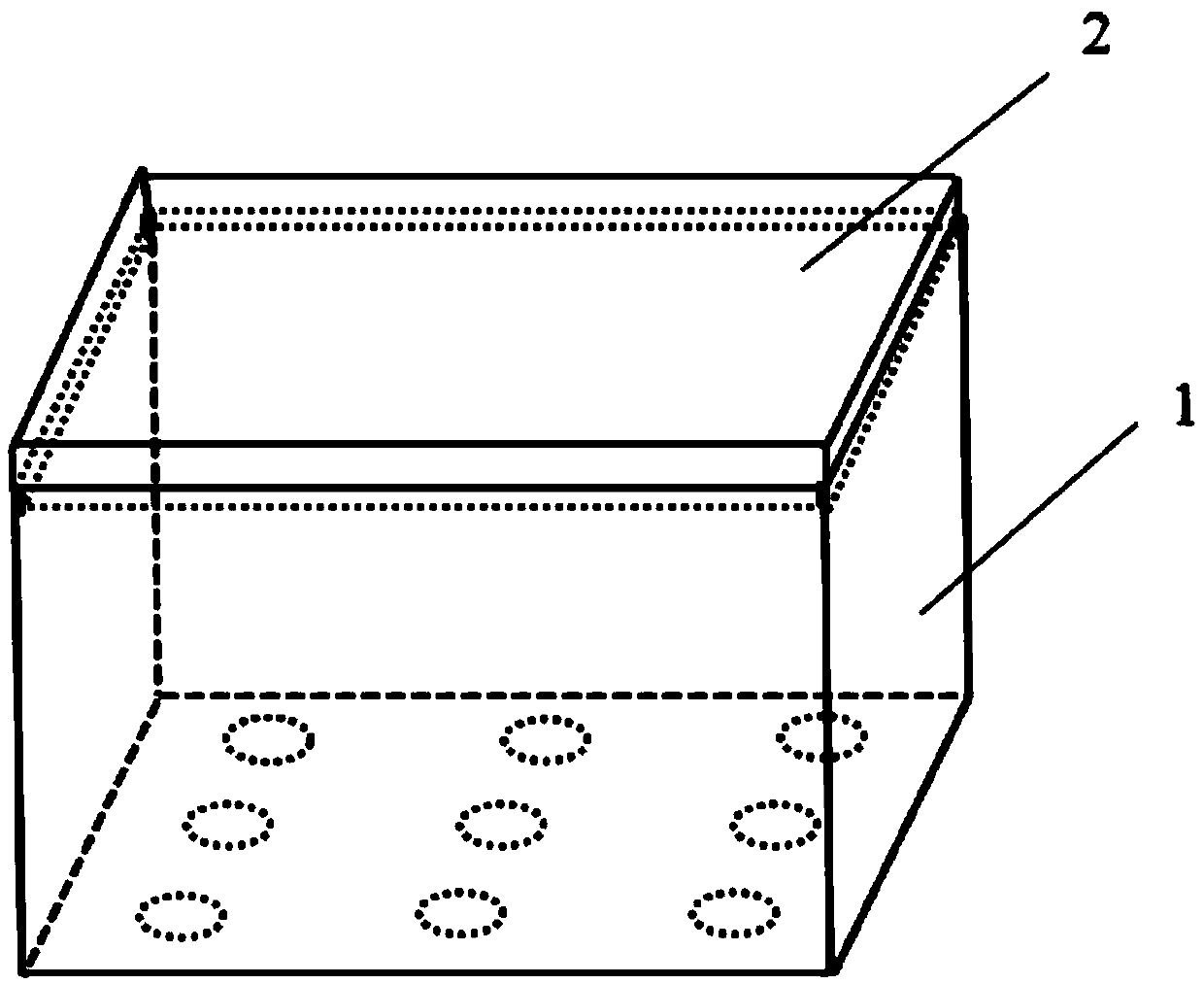

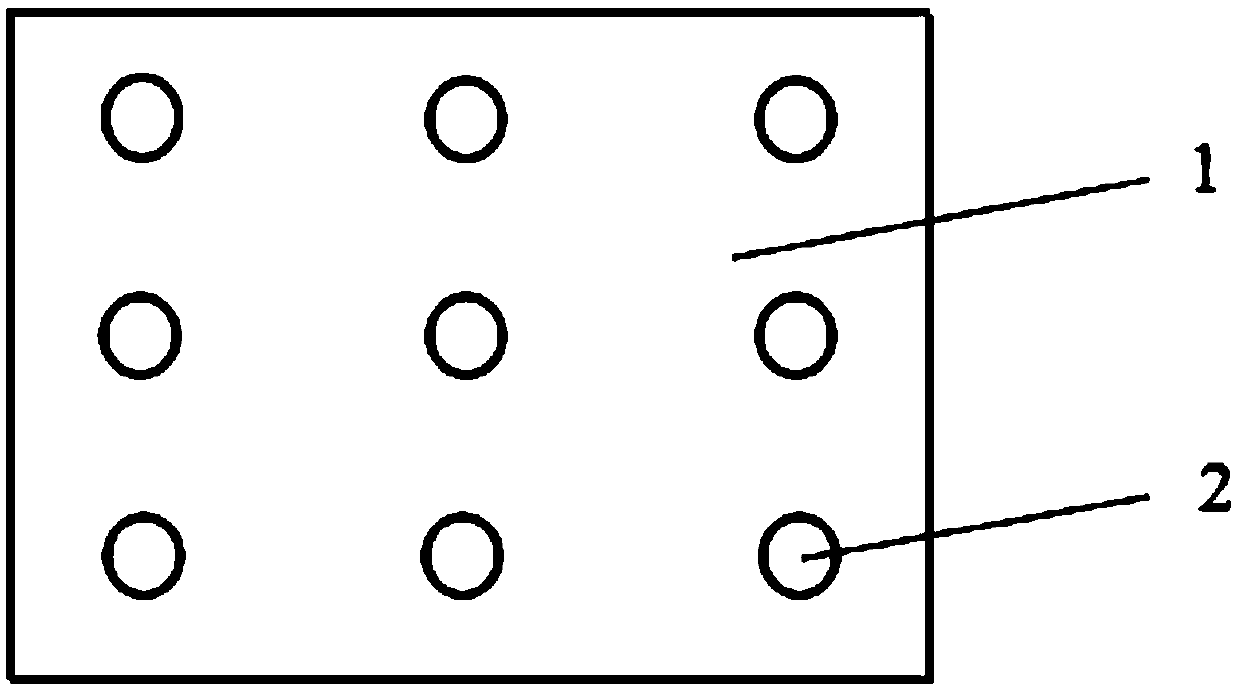

[0048] (2) Packing of sweet corn: the picked fresh sweet corn is placed...

Embodiment 2

[0054] Storage Example 2, the salt concentration is 1.75% flowing ice processing sweet corn

[0055] 1. Materials

[0056] One with embodiment 1.

[0057] Second, the salt concentration is 1.75% mobile ice treatment and storage

[0058] (1) Preparation of pre-cooling medium: adding sodium chloride (NaCl) to water, stirring evenly to make a saline mixture with a salt concentration of 1.75%, cooling the prepared saline mixture to a certain temperature, and crystallizing water from the solution, Thereby forming fine spherical ice crystals (the diameter of the ice crystals is 0.2-0.8mm) to obtain flowable ice, which is the required pre-cooling medium and ready for use.

[0059] (2) Packing of sweet corn: the fresh sweet corn after picking is placed in a box with holes.

[0060] (3) Sweet corn treatment: Pour the cooling medium prepared in step (1) into the box in step (2), and it is best if the amount of ice does not exceed the sweet corn. Let stand for 5-10 minutes, filter ou...

Embodiment 3

[0062] Storage Example 3, the salt concentration is 2% fluid ice processing broccoli

[0063] 1. Materials

[0064] One with embodiment 1.

[0065] Second, the salt concentration is 2% mobile ice treatment and storage

[0066] (1) Preparation of pre-cooling medium: adding sodium chloride (NaCl) to water, stirring to make a saline mixture with a salt concentration of 2%, cooling the prepared saline mixture to a certain temperature, and crystallizing water from the solution, Thereby forming fine spherical ice crystals (the diameter of the ice crystals is 0.2-0.8mm) to obtain flowable ice, which is the required pre-cooling medium and ready for use.

[0067] (2) Packing of sweet corn: the fresh sweet corn after picking is placed in a box with holes.

[0068] (3) Sweet corn treatment: Pour the cooling medium prepared in step (1) into the box in step (2), and it is best if the amount of ice does not exceed the sweet corn. Let stand for 5-10 minutes, filter out the excess water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com