Hydraulic control butterfly valve

A hydraulic control butterfly valve, butterfly valve technology, applied in the direction of lifting valve, valve device, engine components, etc., can solve the problem of reducing the accuracy and reliability of the hydraulic control butterfly valve action feedback signal, the adjustment position cannot be completed accurately, and the work efficiency of maintenance personnel is affected. problem, to achieve the effect of simple structure, flexible use and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

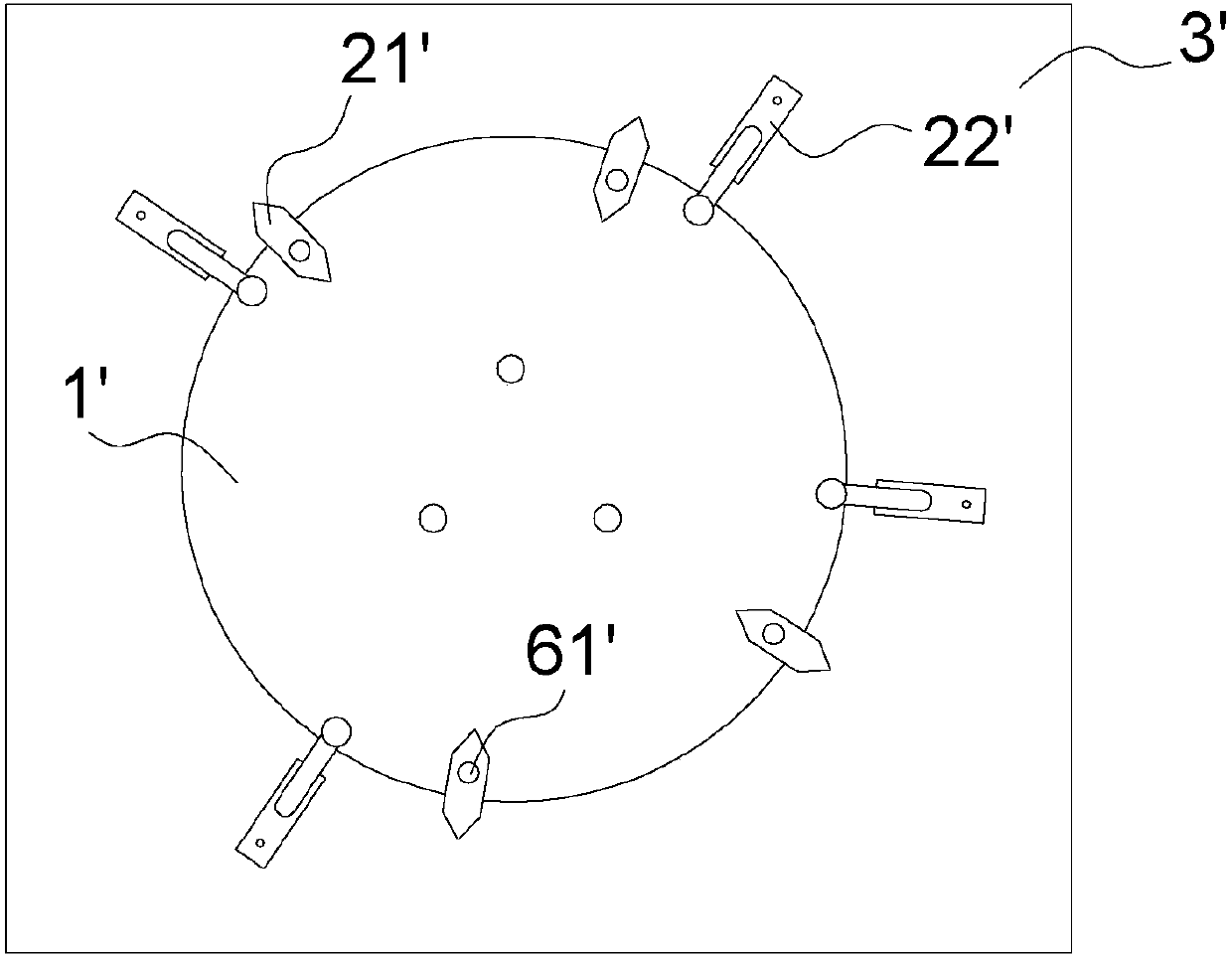

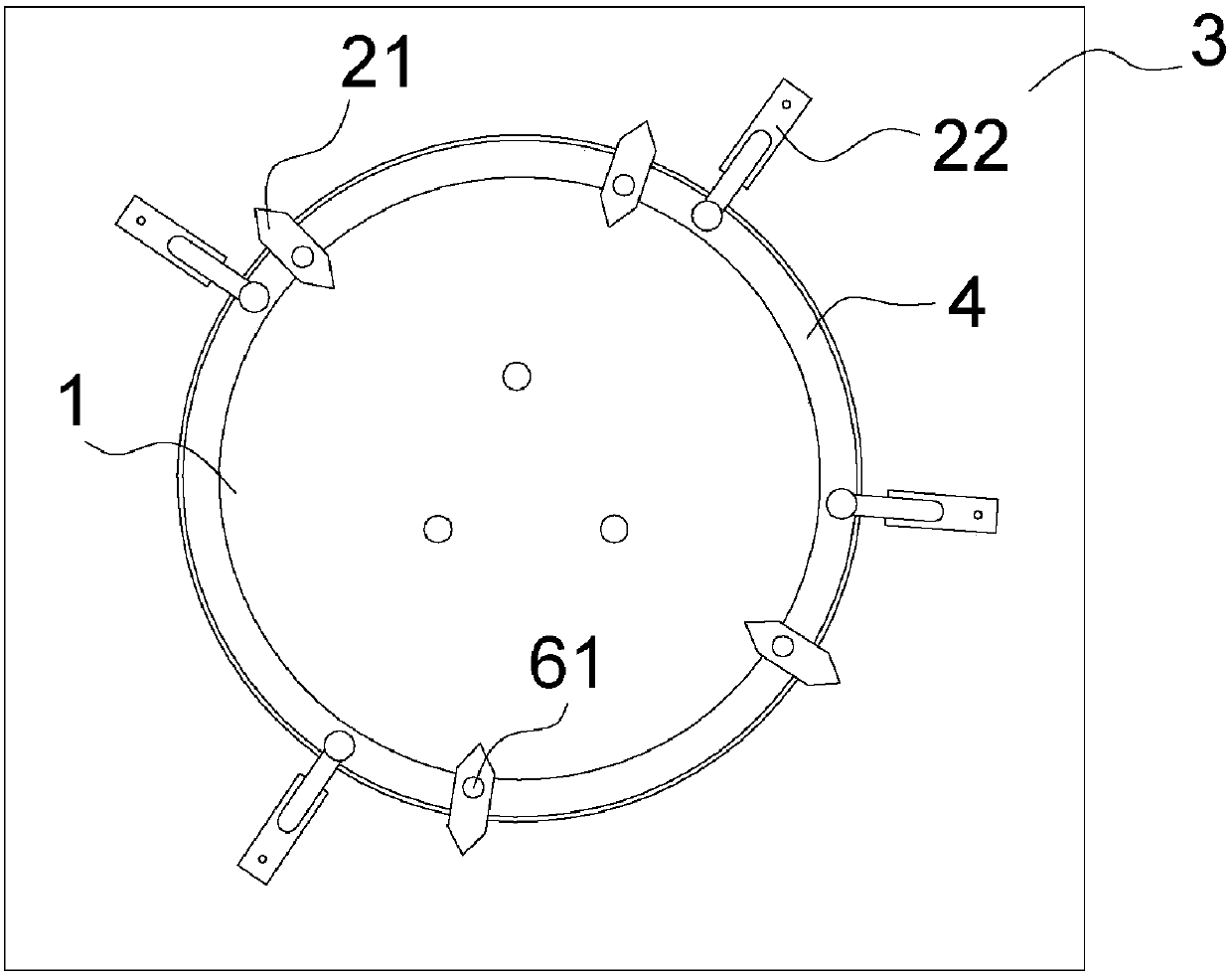

[0046] Such as image 3 , Figure 4 As shown, the hydraulic control butterfly valve in this embodiment includes a rotating disk 1, a butterfly valve bracket 3 matched with the rotating disk 1, and a stroke feedback device installed thereon. The travel feedback device includes: a circumferential groove 4 located on the outer circumferential position of the rotating disk 1, the notch 41 of which is opened forward, and the radial dimension of the groove bottom 42 is larger than the radial dimension of the notch 41, so that its section is inverted T-shaped; And the limit switch 22 located on the butterfly valve bracket 3, used to control the transmission of the feedback signal; and the touch module 21 located on the rotating disk 1, which rotates with the rotating disk 1, used to touch the limit switch 22; and the connecting piece, its two ends Connect with the touch module 21 and the groove bottom 42 of the circumferential groove 4 respectively, the radial dimension of one end o...

Embodiment 2

[0048] Such as Figure 5 , Figure 6 As shown, the difference between this embodiment and the above-mentioned embodiments is that a mounting hole 7 is provided at the position corresponding to the circumferential groove 4 at the rear of the rotating disk 1, and the radial dimension of the mounting hole 7 is larger than the dimension along the direction at the end of the connecting piece at the bottom of the groove. , so that the end of the connector located at the bottom of the groove can be placed in the bottom of the circumferential groove 42 from the mounting hole 7 . And the connectors in this embodiment are screws 61 and nuts 62 that cooperate with each other. The screws 61 are inserted into the corresponding holes on the touch module 21 from the front and penetrate the notch 41. The nuts 62 are inserted into the bottom of the circumferential groove 4 from the installation hole 7 42 and tighten with screw 61.

[0049] The number of mounting holes 7 in this embodiment ma...

Embodiment 3

[0051] Such as Figure 7 , Figure 8 As shown, the difference between this embodiment and the above-mentioned embodiments is that the travel feedback device also includes an auxiliary part 5, which is used to assist the movement and positioning of the touch module 21, which is arranged on the rear side of the touch module 21 and located in the notch 41 Among them, the dimension along the radial direction of the rotating disk 1 is slightly smaller than or equal to the dimension of the notch 41 along this direction, and a through hole is provided on it, which can be connected with the touch module 21 as a whole through a connecting piece. The auxiliary part can prevent the screw 61 from tilting and shaking relative to the axial direction in the notch, thereby avoiding affecting the sensitivity of the travel feedback device. Moreover, when adjusting the stroke feedback device, the auxiliary part can also reduce or even avoid friction between other parts and the notch, which is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com