Transmission reverse gear shaft assembly

A technology of reverse gear shaft and transmission, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problem of high cost of thrust needle roller bearings, reduce the risk of wear and ensure sufficient lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

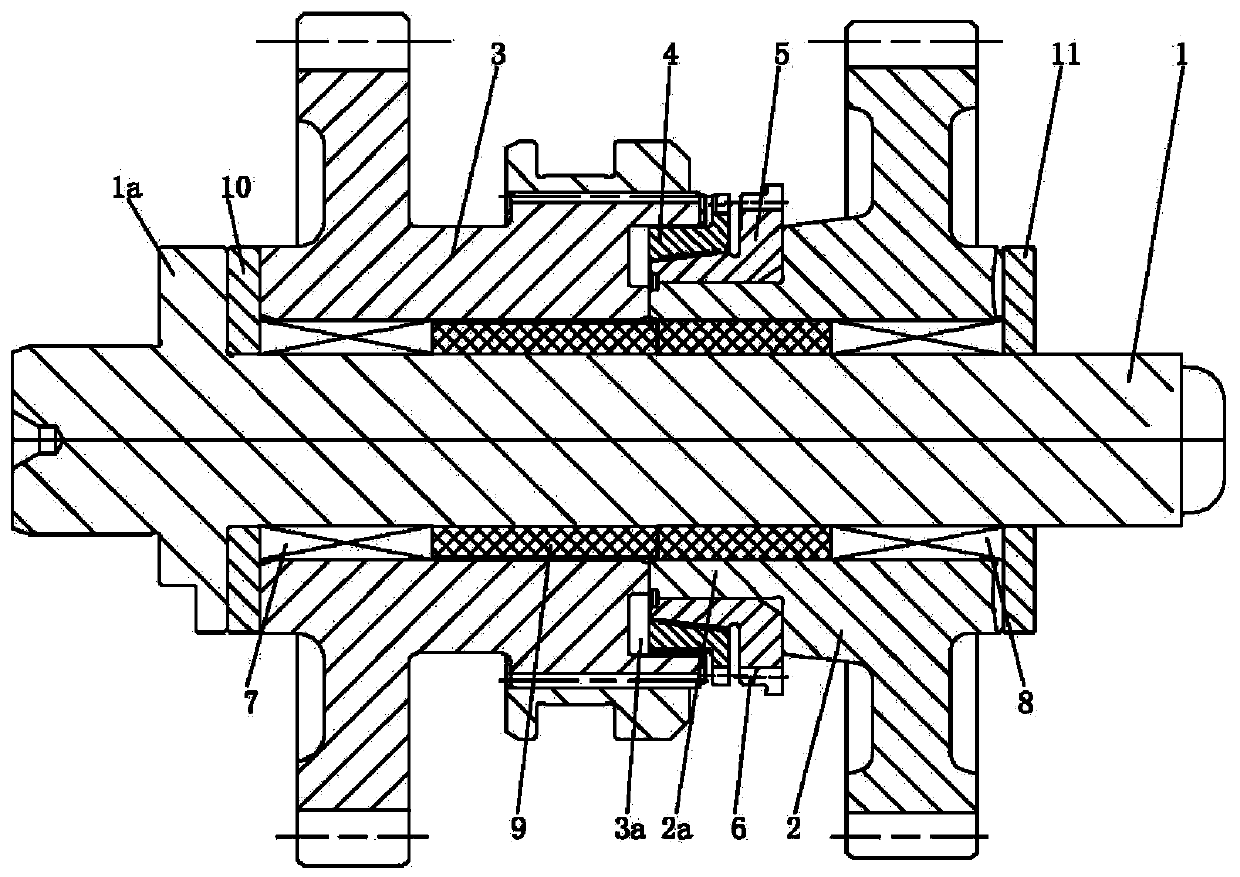

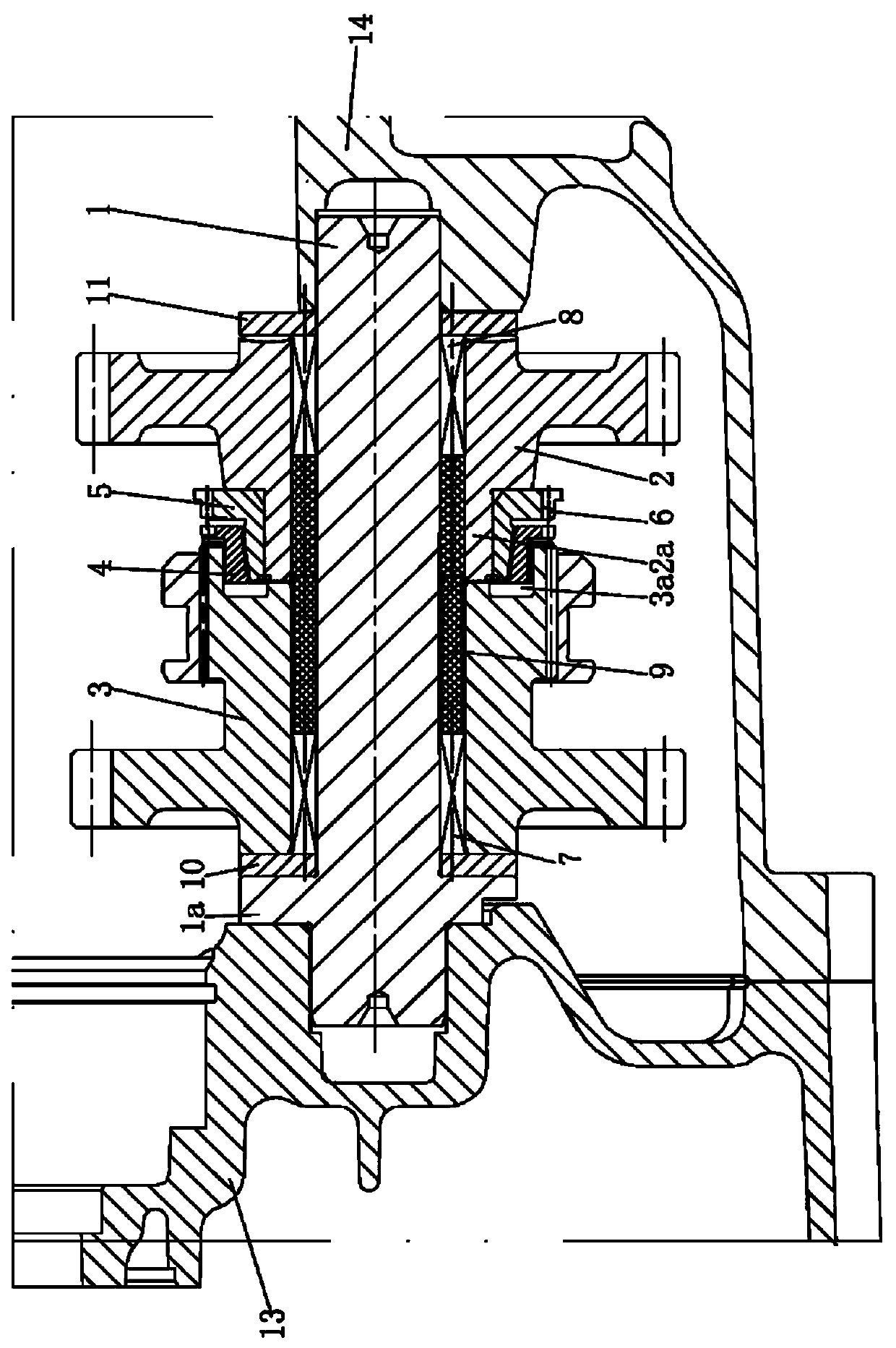

[0029] Such as figure 1 and figure 2 As shown, the transmission reverse gear shaft assembly of the present invention includes a reverse gear shaft 1, a reverse gear assembly, a support assembly, a first wear-resistant gasket 10, and a second wear-resistant gasket 11, and the two ends of the reverse gear shaft 1 are respectively It is connected with the left case body 13 and the right case body 14 of the transmission case, the support assembly is sleeved on the reverse shaft 1, at least a part of the support assembly is connected with the reverse shaft 1, the reverse gear assembly is sleeved on the support assembly, and the reverse At least a portion of the range gear assembly is connected to the support assembly.

[0030] Such as figure 1 and figure 2 The reverse gear assembly shown includes a first gear 2, a second gear 3, a synchronous ring 4, and a synchronous cone hub 5. One end of the first gear 2 is provided with a shaft 2a, and the synchronous cone hub 5 is sleeved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com