Method for fixing concrete column beam formwork chamfering strips

A technology of concrete columns and fixing methods, applied in covering/lining, construction, building construction, etc., can solve problems affecting project progress, slow construction speed, and difficult nail size, so as to reduce the comprehensive cost of construction, improve operating efficiency, The effect of ensuring the quality of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Concrete column beam formwork chamfering strip fixing method of the present invention comprises the following steps:

[0034] a. Prepare concrete column beam formwork, air nail gun and air nail

[0035] Concrete column and beam formwork is made of bamboo plywood, and commercially available air nail guns are purchased, which are equipped with F25 air nails; in this embodiment, air nail gun ST60 is used, and F25 air nails are used. The thickness of the bamboo plywood of the column and beam formwork is 18mm.

[0036] b. Prefabricated chamfering strips

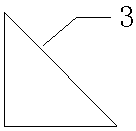

[0037] figure 2 It is a schematic cross-sectional view of a chamfered strip according to an embodiment of the present invention. Bamboo plywood is used as material to prefabricate chamfering strips. The chamfering strips are long and the length is determined according to the needs of the concrete column and beam formwork. The corners are all 45°, and the thickness of the bamboo plywood for the chamfering strips is 7mm....

Embodiment 2

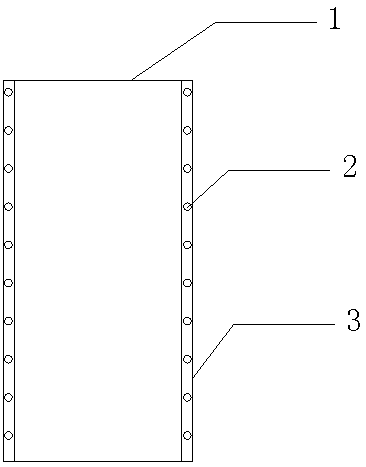

[0041] This embodiment illustrates that the chamfering strips in the concrete column formwork are fixed, and the technical measures for preparing the concrete column beam formwork, air nail gun and air nails, and the prefabricated chamfering strips are the same as in Example 1. The frame-shaped concrete column formwork in the vertical state is produced by the conventional method, and the four prefabricated chamfering strips are vertically placed on the four corners of the frame-shaped concrete column formwork, so that the right angles formed by the four-corner formwork of the frame-shaped concrete column formwork and the angle of the chamfering strips For right-angle stacking, use an air nail gun with F25 air nails, and fix the chamfered strips in the concrete column formwork with several air nails. The driving positions of the plurality of air nails are in a straight line state, and the driving distance between two adjacent air nails of the plurality of air nails is 100mm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com