Novel energy-consuming support assembly connection structure

A technology for energy-dissipating supports and connecting structures, which is applied to building components, building types, protected buildings/shelters, etc., can solve the problems of confining concrete losing restraint and anti-buckling effect, reducing energy dissipation capacity, etc., and achieving excellent friction The effect of damping energy consumption, improving energy consumption efficiency, and sufficient energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

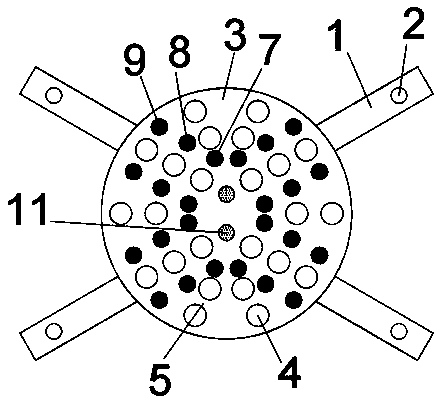

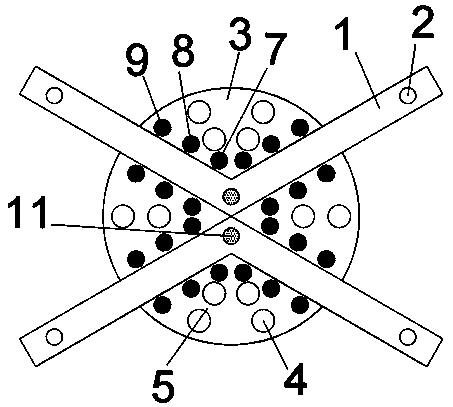

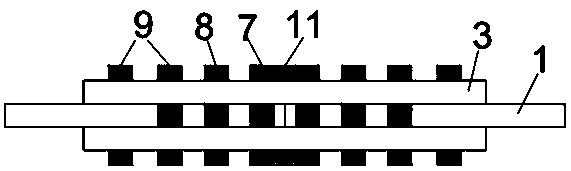

[0017] Example: such as Figure 1~Figure 5 As shown, a new type of energy-dissipating support assembled connection structure, including right-angle friction connection 1, screw hole 2, friction energy-dissipating plate 3, inner circular hole 4, energy-dissipating rib 5, lead pin hole 6, first-level lead pin 7. Second-level lead pin 8, third-level lead pin 9, rivet hole 10 and rivet 11; the new energy-dissipating support assembled connection structure is composed of right-angle friction connection 1, friction energy-dissipating plate 3, first-level lead pin 7, two The first-level lead pin 8, the third-level lead pin 9 and the rivet 11 are assembled, the top layer and the bottom layer are provided with the friction energy dissipation plate 3, the middle layer is provided with the right-angle friction connection 1, and the right-angle friction connection 1 is provided with the screw hole 2 and the rivet hole 10. A number of internal round holes 4, lead pin holes 6, and rivet hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com