Conductive polybutylene as well as preparation method and purpose thereof

A polybutene and polyethylene technology, applied in the field of conductive polybutene, can solve the problems of low hazardous waste treatment rate, limited treatment volume, high hazardous waste, and achieve excellent acid and alkali resistance and solvent resistance, excellent electrical conductivity. performance and mechanical properties, the effect of avoiding direct contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

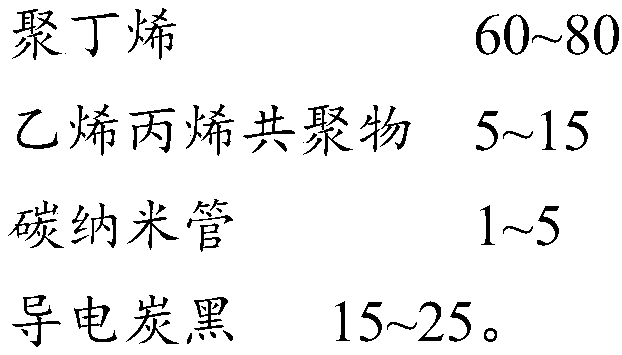

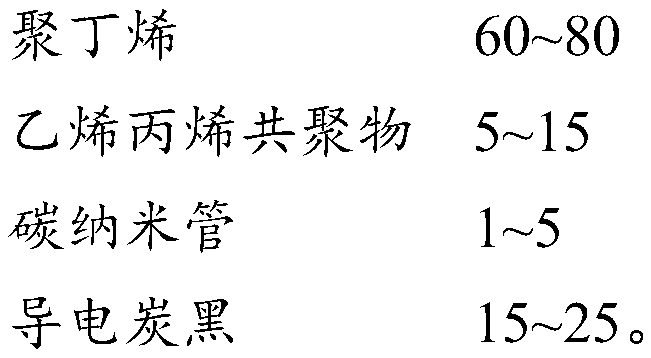

[0052] The preparation method of conductive polybutene as described above, described method comprises the steps:

[0053] The polybutene, ethylene propylene copolymer, conductive carbon black and carbon nanotubes are mixed for internal mixing and molding, and then extruded to obtain conductive polybutene.

[0054] In the present invention, the internal mixing forming can be realized by an internal mixer, for example, by a HAAKE internal mixer. The extrusion can be achieved by means of a twin-screw extruder or a single-screw extruder. The extrusion temperature can be determined by the melting temperature of polybutene and ethylene propylene copolymer, so as to realize normal extrusion molding.

[0055] In a preferred embodiment of the present invention, conduction carbon black and carbon nanotube are heated to remove moisture, then mix with polybutene and ethylene propylene copolymer, further preferably conduction carbon black and carbon nanotube are placed in high It is heat...

Embodiment 1

[0077] 1. Conductive polybutene

[0078] A conductive polybutene is prepared from the following raw materials in parts by weight: polybutene 65, ethylene propylene copolymer 8, carbon nanotube 1, conductive carbon black 22, lubricant 3, and antioxidant 1.

[0079] The polybutene is a polybutene with a melt index of 2 g / min, a melting point of 125° C. and an isotacticity greater than or equal to 96;

[0080] The ethylene propylene copolymer is POE with a melt index of 2 g / min and an ethylene content of 13 wt%, the lubricant is pentaerythritol stearate, and the antioxidant is antioxidant 1010.

[0081] 2. Preparation method of conductive polybutene

[0082] (1) Put conductive carbon and carbon nanotubes into a high-mixer, preheat at a speed of 300r / min for 10min, and remove moisture;

[0083] (2) Add lubricant and antioxidant, and process for 10-25min at a rotating speed of 1500r / min;

[0084] (3) Add polybutene and ethylene propylene copolymer, mix with 100r / min rotating spe...

Embodiment 2-3

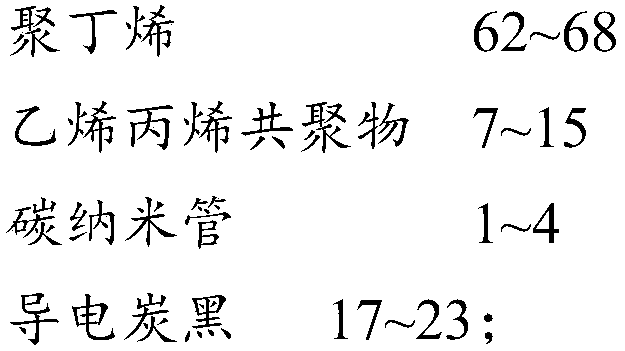

[0087] The difference between embodiment 2-3 and embodiment 1 is that the consumption of each raw material is different, specifically as shown in table 1:

[0088] The consumption of each raw material in the embodiment 2-3 of table 1

[0089]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com