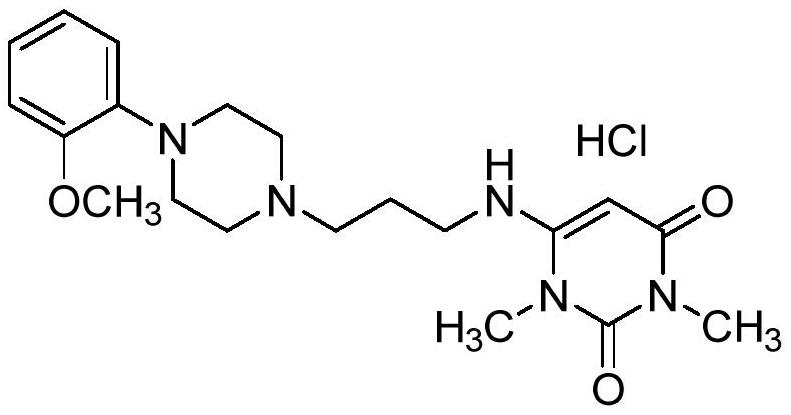

A kind of preparation method of urapidil hydrochloride

A technology of uradil hydrochloride and uradil, which is applied in organic chemistry and other fields, and can solve the problems of large pollution, low yield, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

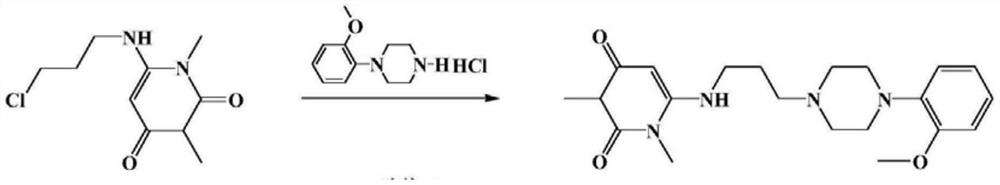

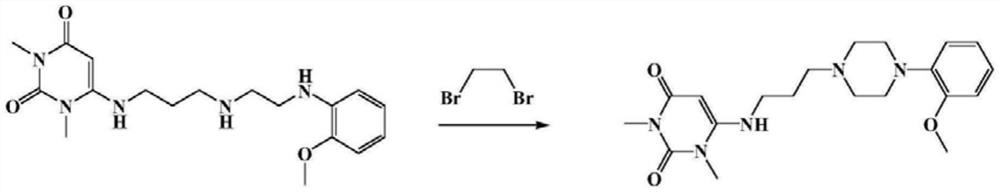

Method used

Image

Examples

example 1

[0032] The preparation of example 1 urapidil hydrochloride

[0033] A. Preparation of Urapidil

[0034] Add 3-[4-(2-methoxyphenyl)piperazin-1-yl]propylamine (50.00g, 0.20mol) and 6-chloro-1,3-dimethylurea to a 500ml clean three-necked reaction flask Pyrimidine purified water (35.01g, 0.20mol), sodium hydroxide (24.06g, 0.60mol) and purified water (500ml), mechanically stirred, heated to 60°C for 2 hours, cooled to room temperature, suction filtered, and the filter cake was ℃ blast drying for 6 hours to obtain 41.2 g of urapidil with a yield of 53.0% and a purity of 96.5%.

[0035] B. Preparation of Urapidil Hydrochloride

[0036] Add absolute ethanol (200.00g) and urapidil (20.00g, 0.05mol) to a 500ml clean three-necked reaction flask and heat up to 70-80°C, dropwise add a mixed solution of hydrochloric acid and ethanol solution (7.32g concentrated hydrochloric acid and 8.00g After the addition, keep stirring at 70-80°C for 1.0h, cool down to room temperature, filter with s...

example 2

[0037] The preparation of example 2 urapidil hydrochloride

[0038] A. Preparation of Urapidil

[0039] Add 3-[4-(2-methoxyphenyl)piperazin-1-yl]propylamine (50.00g, 0.20mol) and 6-chloro-1,3-dimethylurea to a 500ml clean three-necked reaction flask Pyrimidine purified water (35.01g, 0.20mol), potassium hydroxide (33.66g, 0.60mol) and purified water (500ml), stirred mechanically, heated to 60°C for 2 hours, cooled to room temperature, suction filtered, and the filter cake was ℃ blast drying for 6 hours to obtain 38.9 g of urapidil with a yield of 50.1% and a purity of 95.8%.

[0040] B. Preparation of Urapidil Hydrochloride

[0041] Add absolute ethanol (200.00g) and urapidil (20.00g, 0.05mol) to a 500ml clean three-necked reaction flask and heat up to 70-80°C, dropwise add a mixed solution of hydrochloric acid and ethanol solution (7.32g concentrated hydrochloric acid and 8.00g After the addition, keep stirring at 70-80°C for 1.0h, cool down to room temperature, filter wit...

example 3

[0043] Preparation of Urapidil Hydrochloride

[0044] A. Preparation of Urapidil

[0045] Add 3-[4-(2-methoxyphenyl)piperazin-1-yl]propylamine (50.00g, 0.20mol) and 6-chloro-1,3-dimethylurea to a 500ml clean three-necked reaction flask Pyrimidine purified water (35.01g, 0.20mol), anhydrous sodium carbonate (63.59g, 0.60mol) and purified water (500ml), stirred mechanically, heated to 60°C for 2 hours, cooled to room temperature, suction filtered, and the filter cake was 66.23 g of urapidil was obtained by blast drying at 50°C for 6 hours, with a yield of 85.2% and a purity of 97.9%.

[0046] B. Preparation of Urapidil Hydrochloride

[0047] Add dehydrated ethanol (400.00g) and urapidil (40.00g, 0.10mol) to a 500ml clean three-necked reaction flask and heat up to 70-80°C, add dropwise a mixed solution of hydrochloric acid and ethanol solution (14.64g concentrated hydrochloric acid and 16.00g After the addition, keep stirring at 70-80°C for 1.0h, cool down to room temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com