Adjustable cloth hanging needle combination mechanism used for low-pressure injection molding

A combined mechanism, low-pressure injection molding technology, applied in the direction of coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

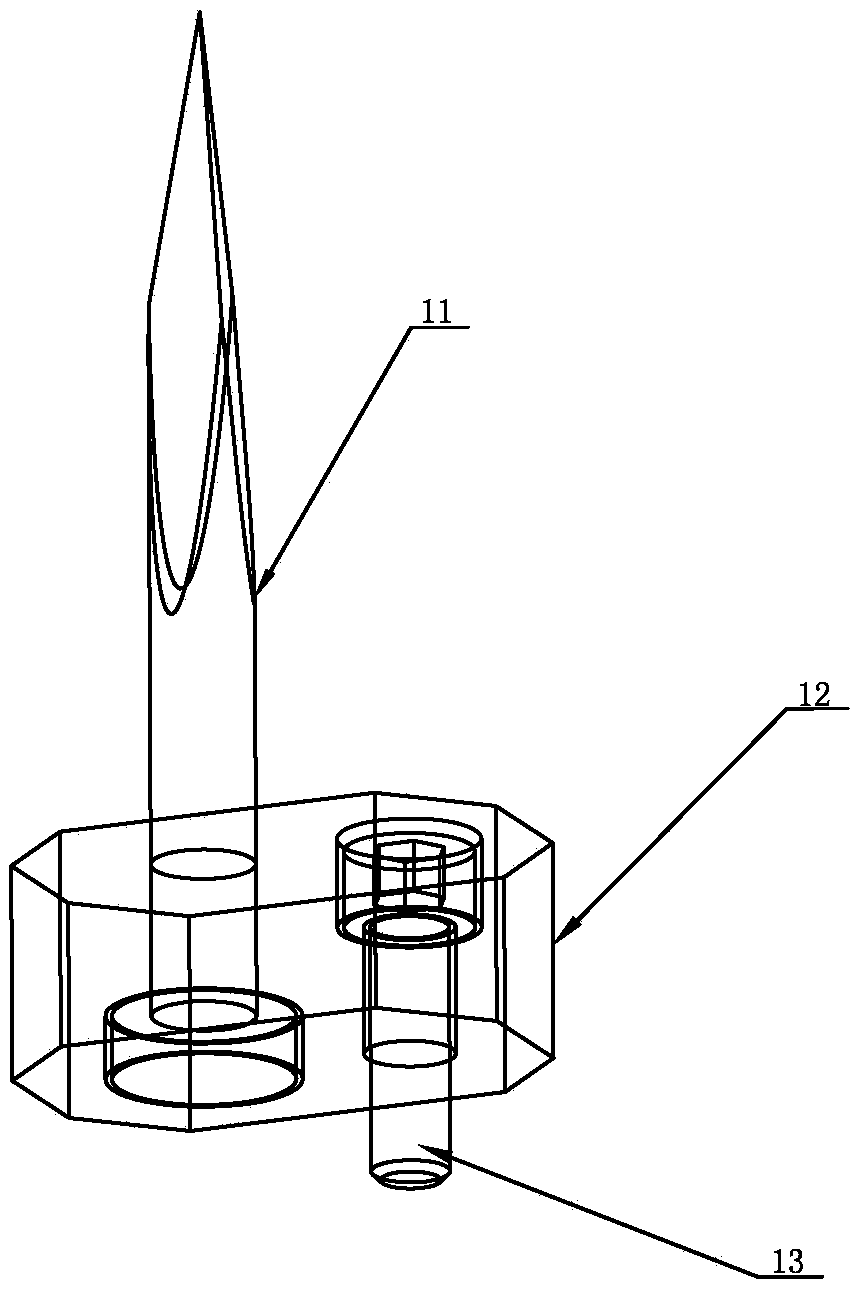

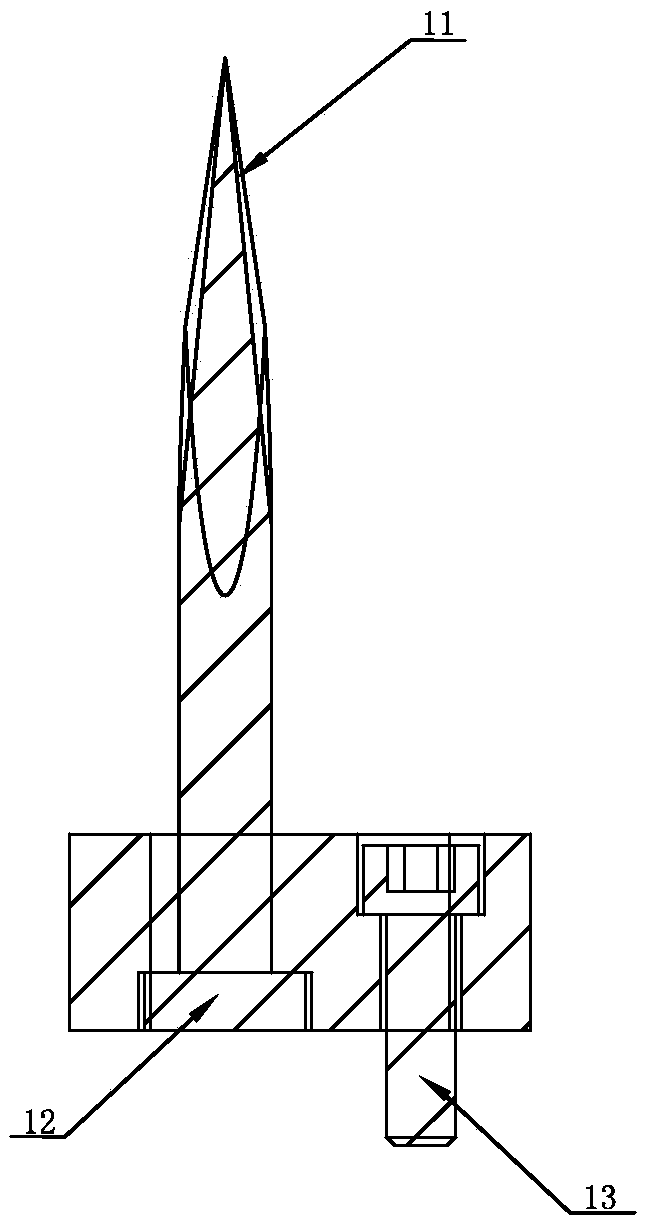

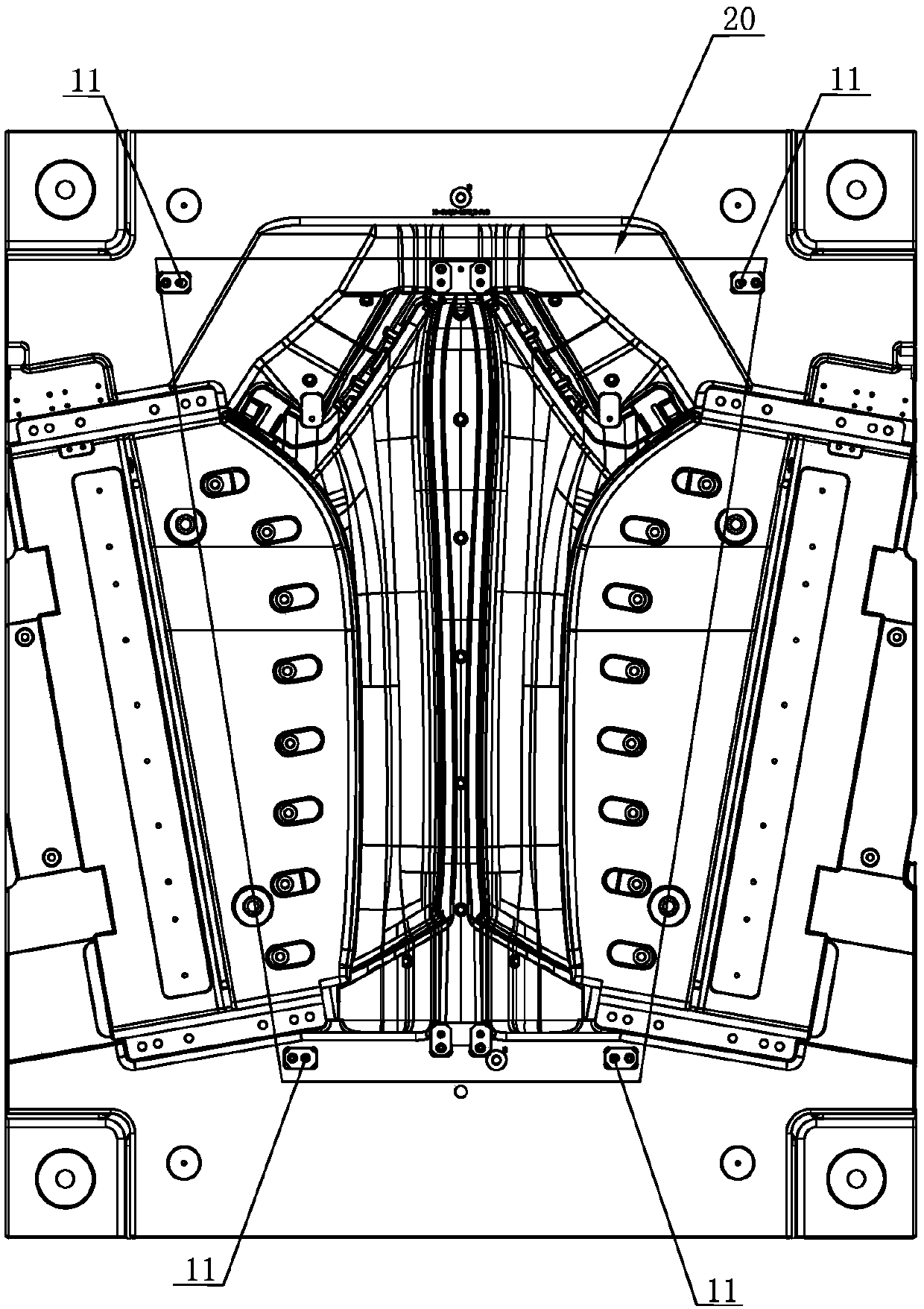

[0014] like Figure 4 , 5 , 6, an adjustable hanging needle combination mechanism for low pressure injection molding, including hanging needle 1, sliding block 2, sliding seat 3, stop block 4, linear spring 5, gasket 7, limit screw 6. The hanging cloth needle 1 includes a needle tip 1-1, a knife edge 1-2, a straight body section 1-3, and a fixed head 1-4. The angle between the two surfaces of the knife edge 1-1 is within 30°, and the straight body section is 1-3 and the fixed head 1-4 are arranged on the sliding block 2, the sliding block 2 is arranged on the sliding seat 3, and the sliding seat 3 is provided with a stop 4 to limit the sliding block 2, and the sliding block 2 is fixed on the limited The limit screw 6 is provided with a linear spring 5, and the limit screw 6 is also provided with a gasket 7 to prevent the linear spring 5 from falling off. The needle tip 1-1 can pierce the fabric, which is convenient for the fabric to hang on the mold. When the fabric cannot b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com