A guide fixture for assembly of long-axis parts and components and its use method

A technology of components and fixtures, which is applied in the field of assembly guide fixtures for long-axis components, can solve problems such as hidden dangers in quality, and achieve the effects of ensuring assembly quality, ensuring safe assembly, improving assembly quality and operating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

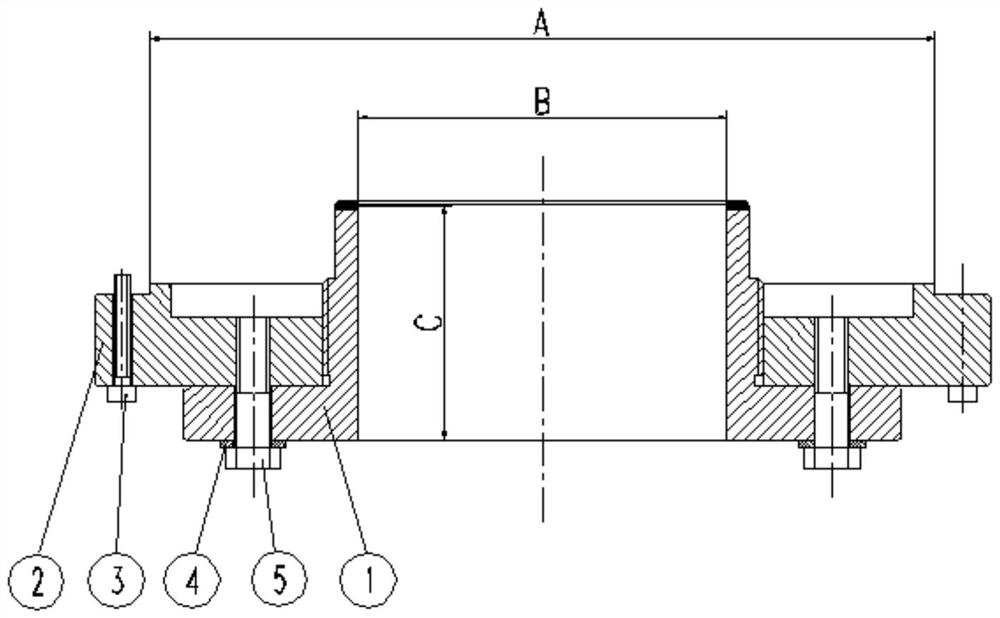

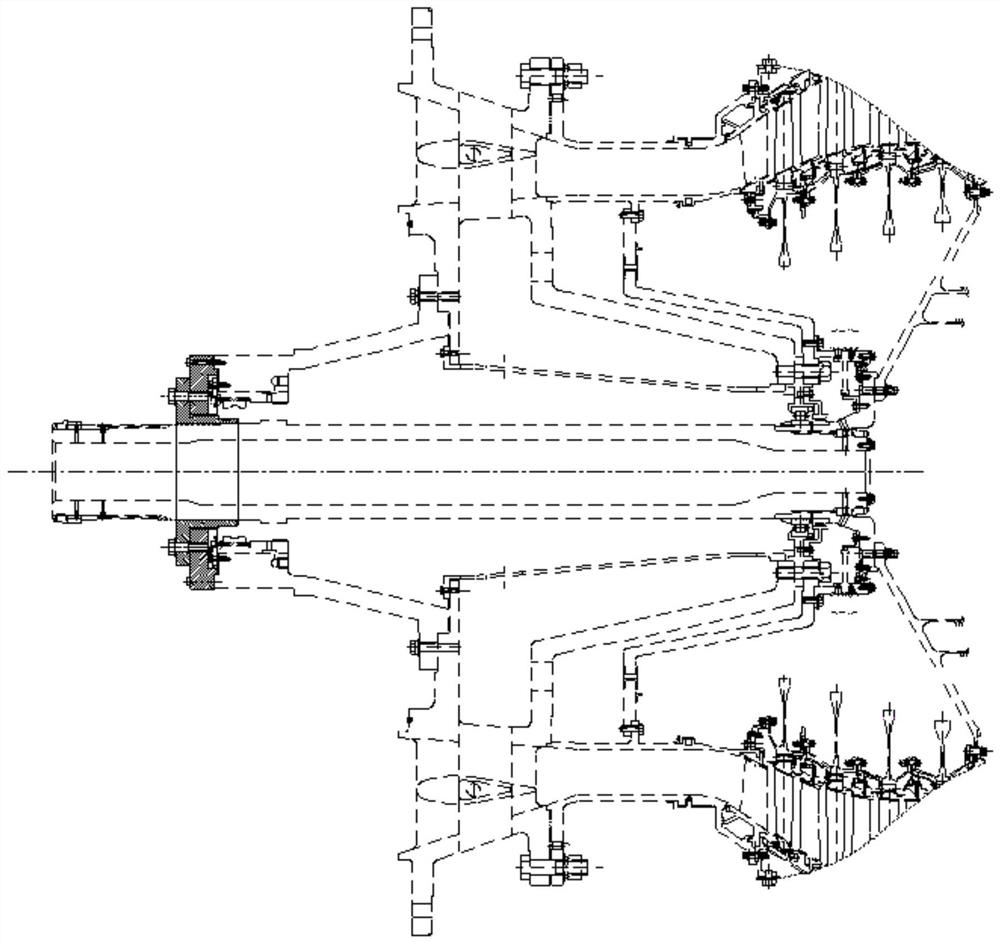

[0031] The present invention provides a guiding jig for assembly of long-axis components, which is characterized in that: said long-axis component assembly guiding jig includes guide shafts, guide discs, screws, washers, and hexagon head bolts; wherein: guide shafts The front surface is coated with protective treatment; the size of the fixture is determined according to the size of the rotor and stator components to be assembled, the size of the guide disc ΦA is consistent with the size of the mounting side of the stator component to be assembled, and the size of the guide shaft ΦB is consistent with the outer ring of the guide shaft to be assembled The outer diameter is consistent, and the height C depends on the height of the assembly structure of the rotor stator seal, which should be higher than the height of the seal.

[0032] A method for using a guide jig for assembly of long-axis components, characterized in that: the specific implementation steps are as follows:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com