Device for satellite assembly

A satellite and mounting board technology, applied in the field of mechanical assembly, can solve problems such as safety hazards, low work efficiency, and dependence on manual operation, and achieve the effect of ensuring safety and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

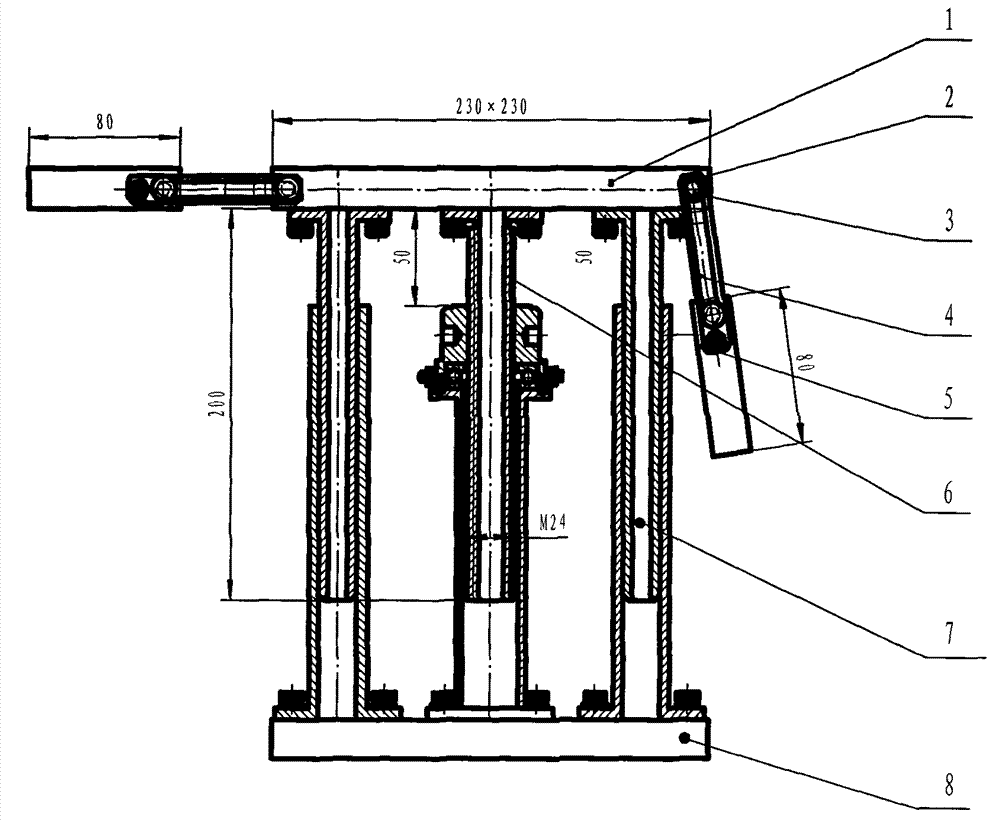

[0028] exist figure 1 The schematic diagram of the device for satellite assembly of the present invention is shown in , as can be seen from the figure, the device includes an upper mounting plate 1, an extension plate 5, a lifting mechanism 6, a guiding mechanism 7, a lower mounting plate 8 and a moving mechanism (not in figure 1 shown in); wherein, the upper mounting plate 1 is respectively connected with an extension plate 5 on both sides through the connecting rod 2, and there is a connection between the upper mounting plate 1 and the lower mounting plate 8 for adjusting the upper The lifting mechanism 6 of the height between the mounting plate 1 and the lower mounting plate 2, the guide mechanism 7 for adjusting the relative position between the upper mounting plate 1 and the lower mounting plate 2; A moving mechanism for adjusting the horizontal position. Each component in the device will be described in detail below.

[0029] The upper mounting plate 1 is used to plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com