Guide wheel and annular fixture combined barrel longitudinal joint welding equipment

A ring clamp, longitudinal seam welding technology, applied in metal processing equipment, manufacturing tools, workpiece edge parts, etc., can solve the problems of reduced work efficiency, harsh welding conditions, inability to maintain straight lines, etc., to improve work efficiency and avoid rework processing. , the effect of avoiding bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

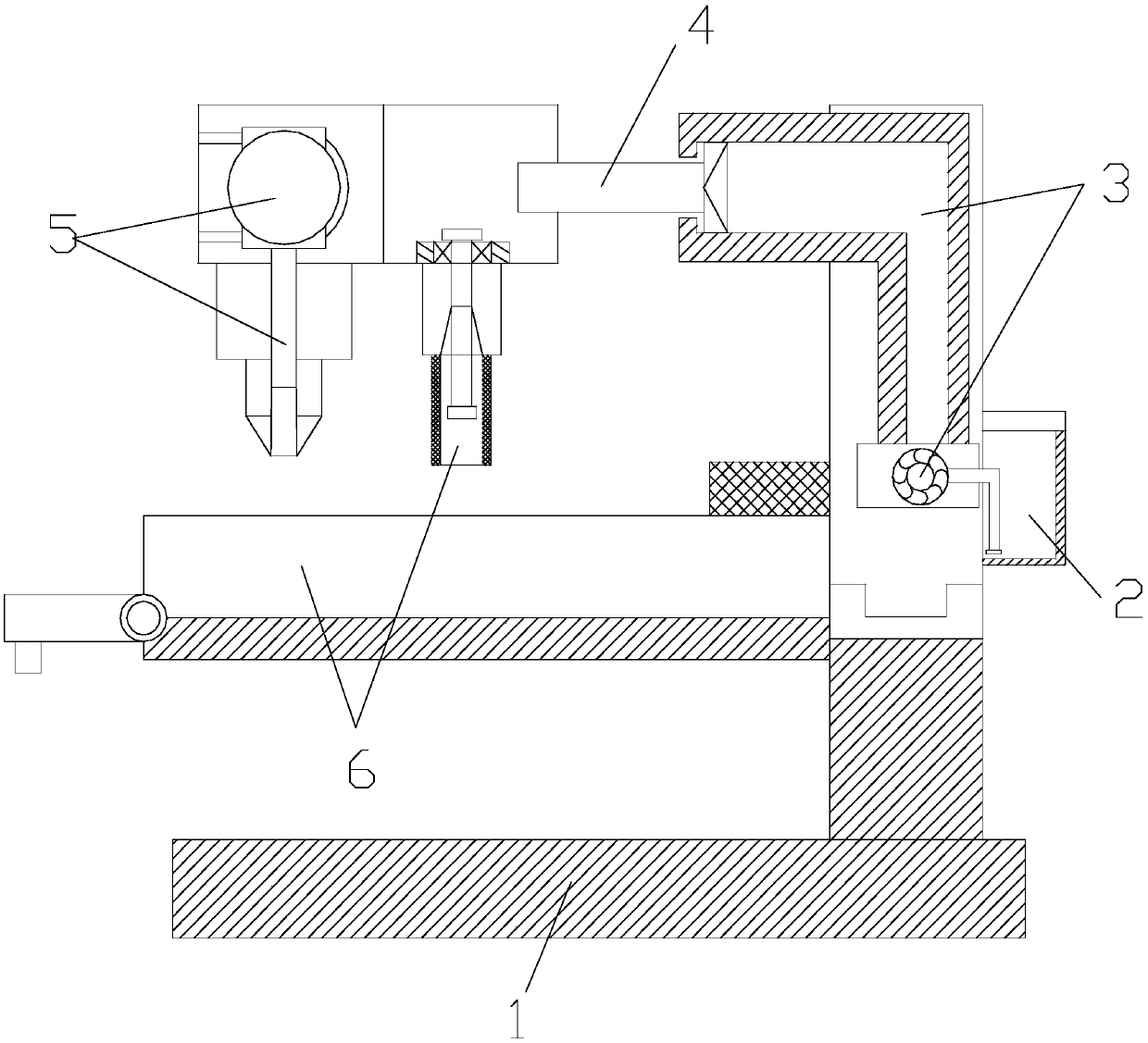

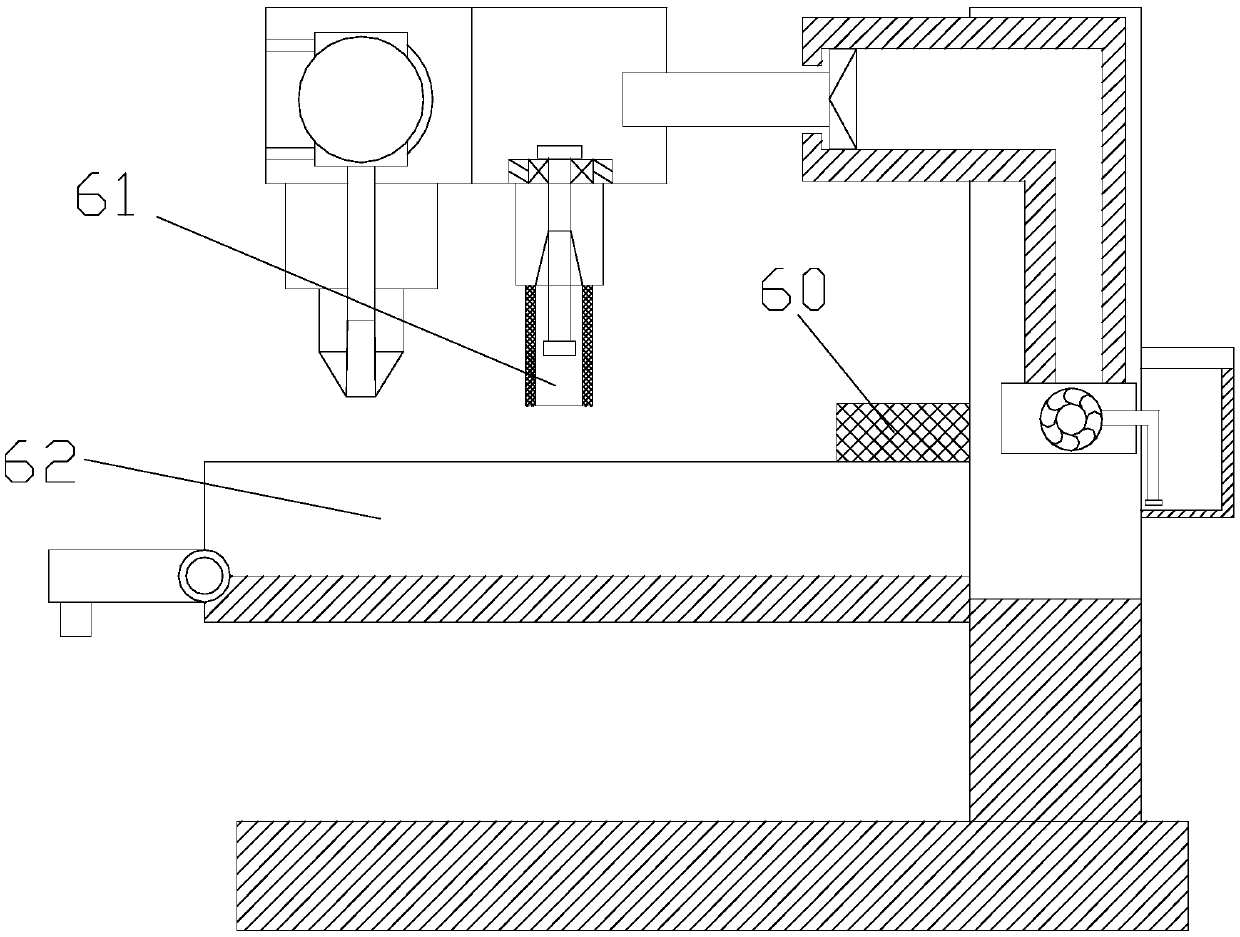

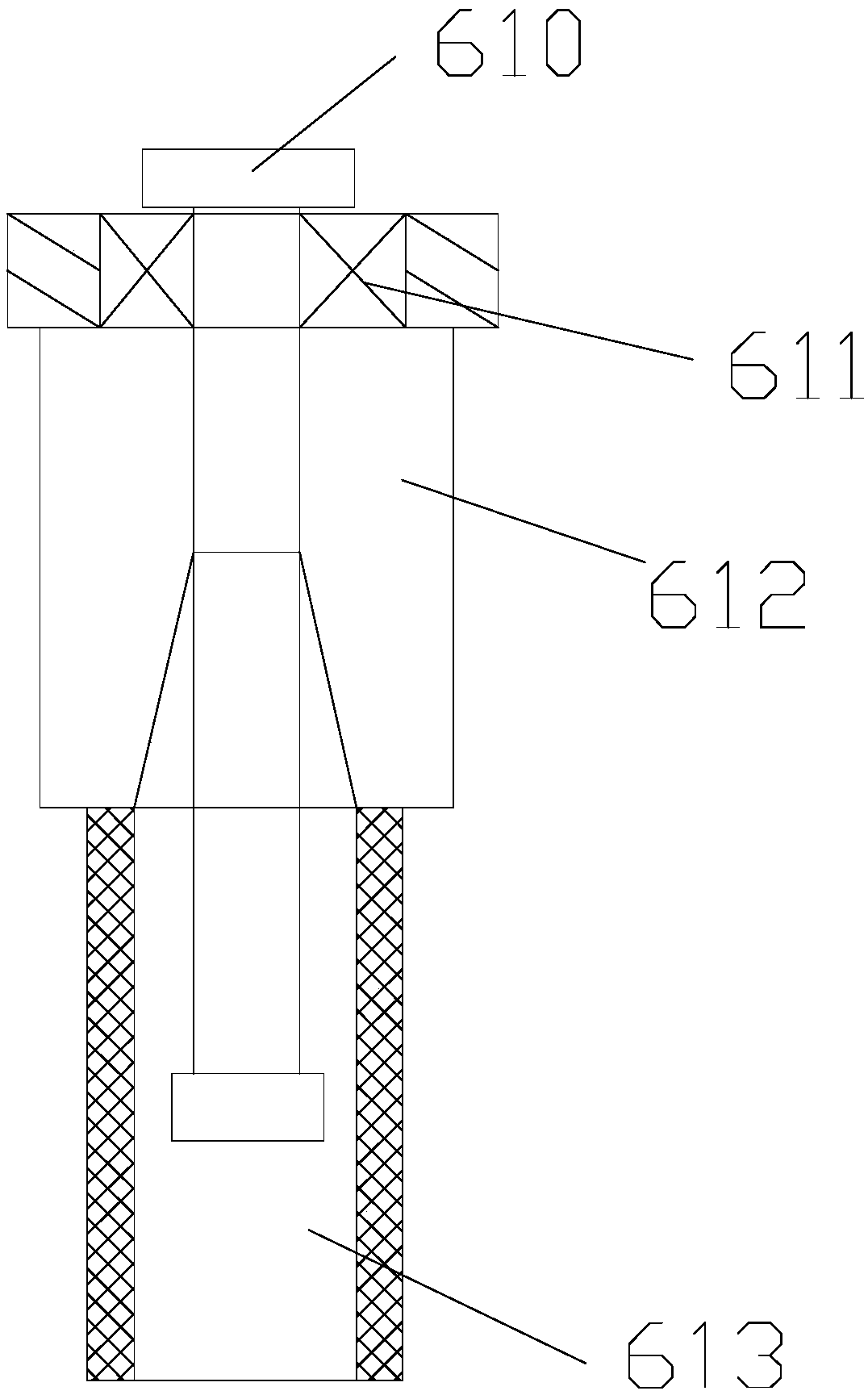

[0029] see figure 1 , the present invention provides a technical scheme of cylinder longitudinal seam welding equipment using guide wheels and ring clamps: its structure includes a base 1, an oil tank 2, a hydraulic expansion seat 3, a piston support rod 4, a welding head 5, and cylinder auxiliary devices 6 , the top of the base 1 is connected to the bottom of the hydraulic expansion seat 3 through slide rails, the left end of the hydraulic expansion seat 3 is fixedly connected to the right end of the cylinder auxiliary device 6, and the top of the cylinder auxiliary device 6 and the inside of the welding head 5 are mechanical connection, the right end of the welding head 5 is embedded with the left end of the piston support rod 4, the right end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com