Suspended turf transplanting machine

A transplanting machine and hanging technology, which is applied in the field of turf transplanting and greening, can solve the problems of increasing the difficulty of operation, reducing the safety of equipment, and large turf, saving space, manufacturing cost and maintenance cost, saving work efficiency and transplanting. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is further described:

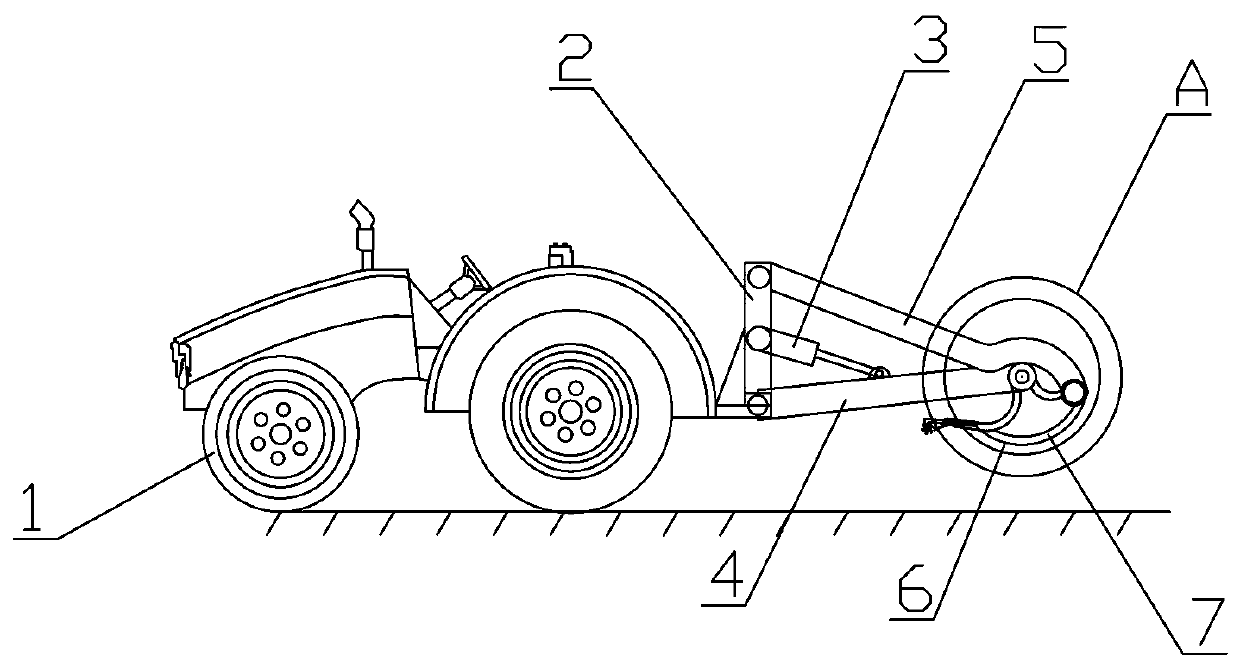

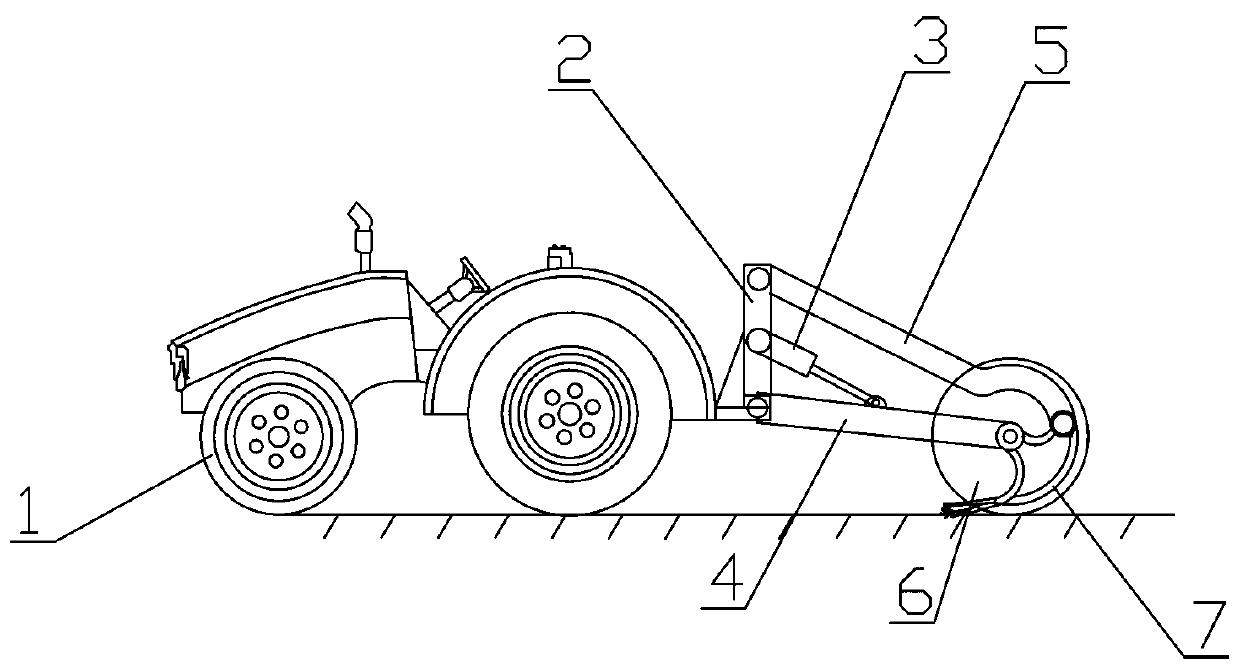

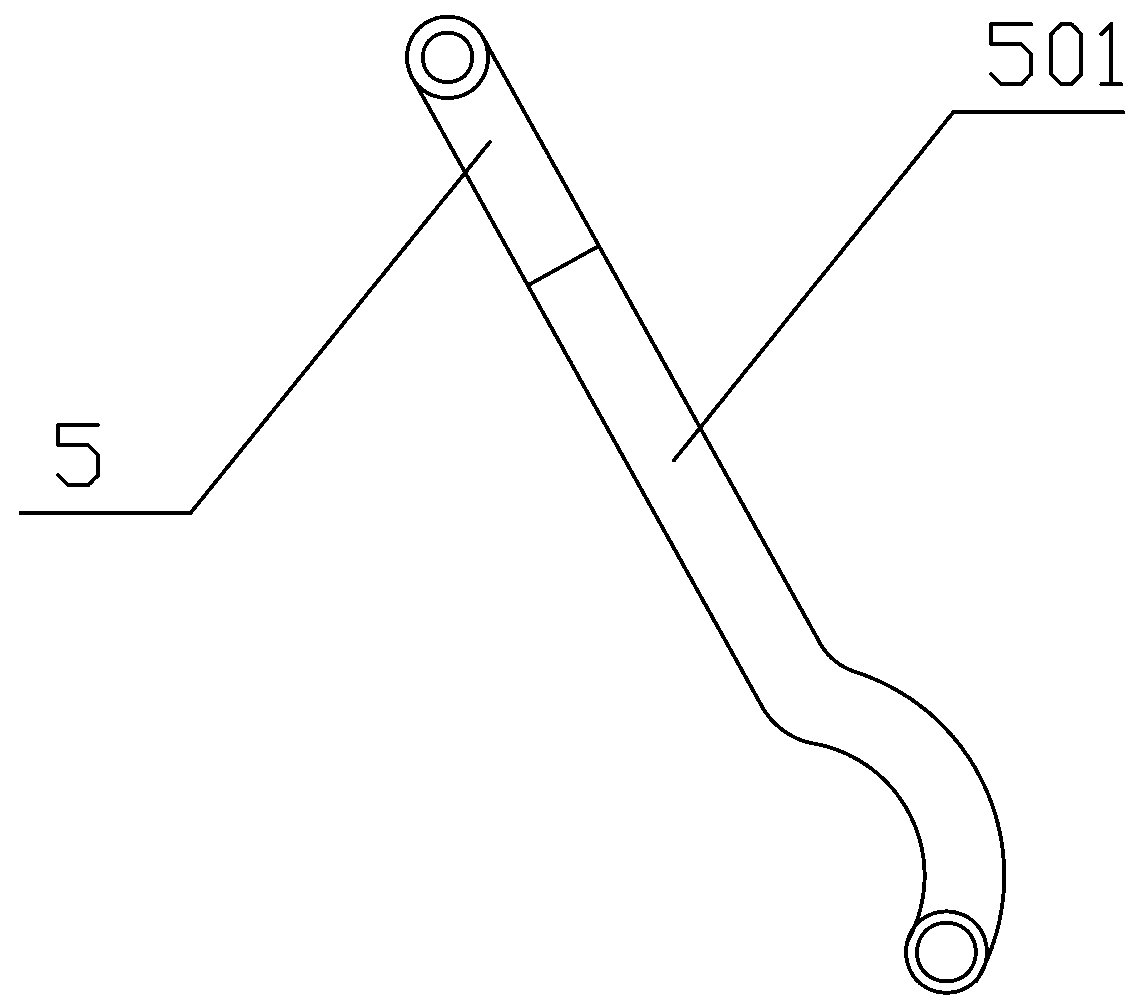

[0032] Such as Figure 1 to Figure 10 Shown, a kind of hanging type turf transplanter comprises fixed frame 2, and described turf transplanter is set on described fixed frame 2, and described turf transplanter comprises connecting rod 4, control arm 5, walking mechanism 6 and knife rest 7, and The connecting rod 4 is a tubular structure, the front end of the connecting rod 4 is rotationally connected to the fixed frame 2, and the rear end of the connecting rod 4 extends laterally to both sides to form a hollow first connecting part 401;

[0033] The first connecting part 401 is connected with a running gear 6 that drives the turf transplanter to move, and the running gear 6 is composed of a central shaft 602 and a walking wheel 601. The central shaft 602 is arranged in the first connecting part 401, and the central shaft Both ends of 602 protrude from bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com