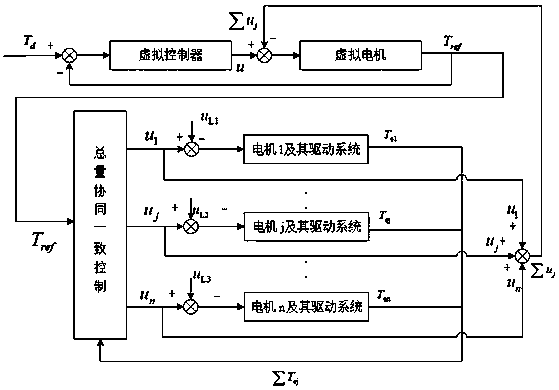

A multi-motor total amount collaborative consistency fault-tolerant control method based on a virtual total axis

A virtual total axle, fault-tolerant control technology, applied in the direction of motor control, multiple motor speed regulation, control system, etc. Fault-tolerant control, the effect of ensuring total consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

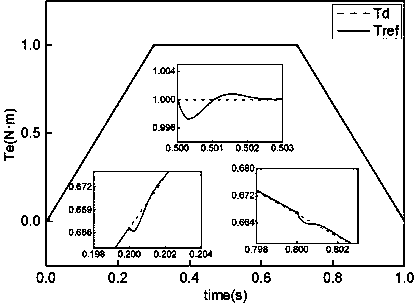

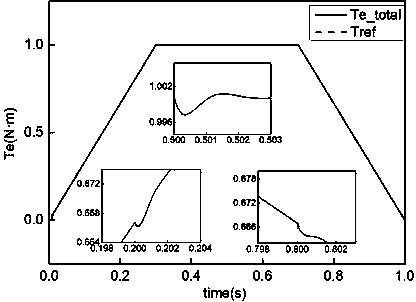

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with specific embodiments.

[0024] According to the existing research "Consensus-based total-amount cooperative tracking control for multi-motor locomotive traction system", the multi-motor mathematical model is specifically:

[0025]

[0026] In the formula, R j , L j Represent the resistance and inductance of the armature circuit, i j is the motor current, ω j is the output angular velocity of the jth motor gearbox, u j is the voltage at the input port of the armature circuit, k ej is the back electromotive force constant, k tj is the transmission ratio of the gearbox. J 0j and J 1j are the moments of inertia of the motor and the gearbox respectively, b 0j and b 1j are the viscous friction coefficients of the motor and the gearbox, k mj is the motor torque constant, Τ Lj is the load torque, Τ ej output torque for the motor.

[0027] Since the multi-motor system is smooth and differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com