A weighing piezoelectric sensor, its preparation method and expressway weighing system

A sensor and heavy-duty technology, applied in the field of highway weighing system, can solve the problems of great influence of traffic flow, plastic deformation, and decreased accuracy, so as to improve life and work stability, good corrosion resistance, and reduce weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 of the present invention provides a weighing piezoelectric sensor.

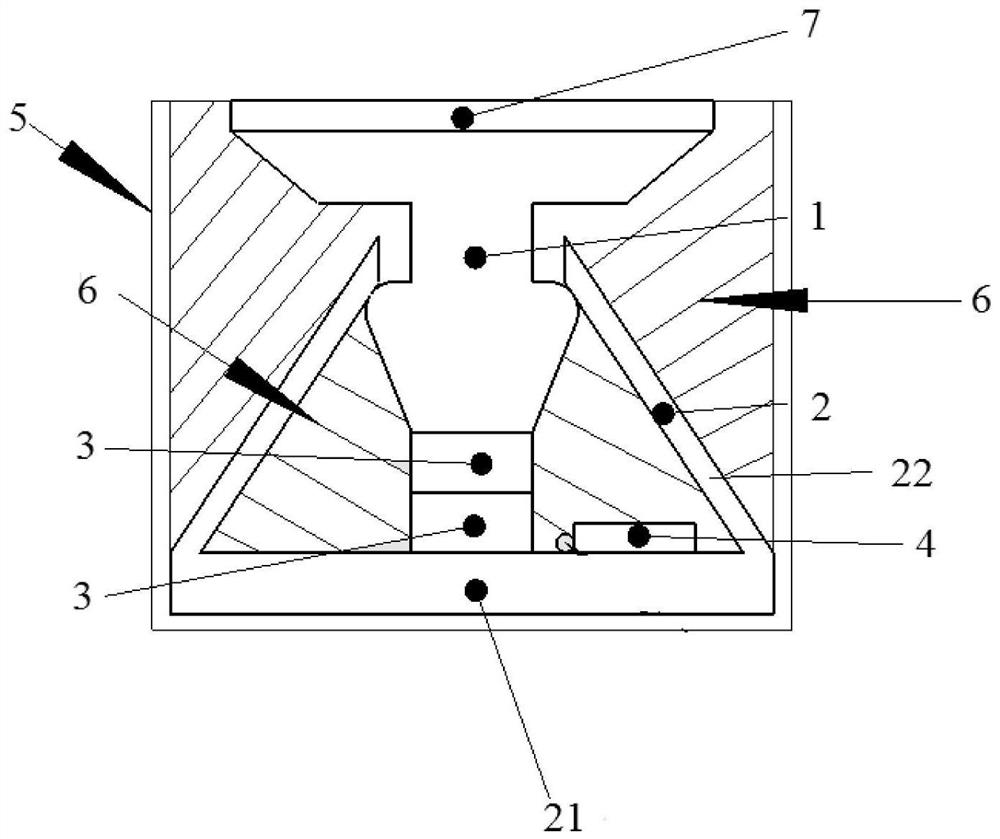

[0048] like figure 1 As shown, the weighing piezoelectric sensor includes:

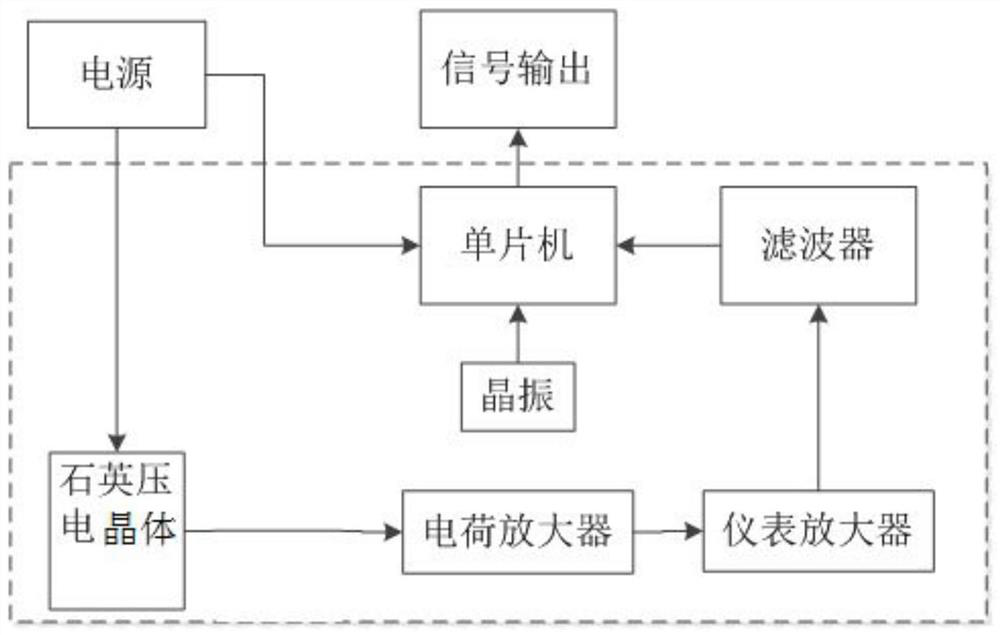

[0049]The pressure conduction structure 1, the preloading force splint 2, the quartz piezoelectric crystal 3 and the signal conditioning circuit 4; Arranged above the bottom plate 21, the two symmetrical pre-tightening side plates 22 clamp the pressure conduction structure 1 above the quartz piezoelectric crystal 3; the quartz piezoelectric crystal 3 is provided with electrode, the quartz piezoelectric crystal is connected to the signal conditioning circuit 4 through the electrode, the quartz piezoelectric crystal 3 is used to weigh the analog signal of the weight applied on the pressure conduction structure, and the The analog signal of weight is sent to the signal conditioning circuit; the signal conditioning circuit 4 is used to convert the analog signal of weight output by the quartz piezoelectric crystal 3 ...

Embodiment 2

[0054] Embodiment 2 of the present invention provides a preferred embodiment of the weighing piezoelectric sensor of the present invention.

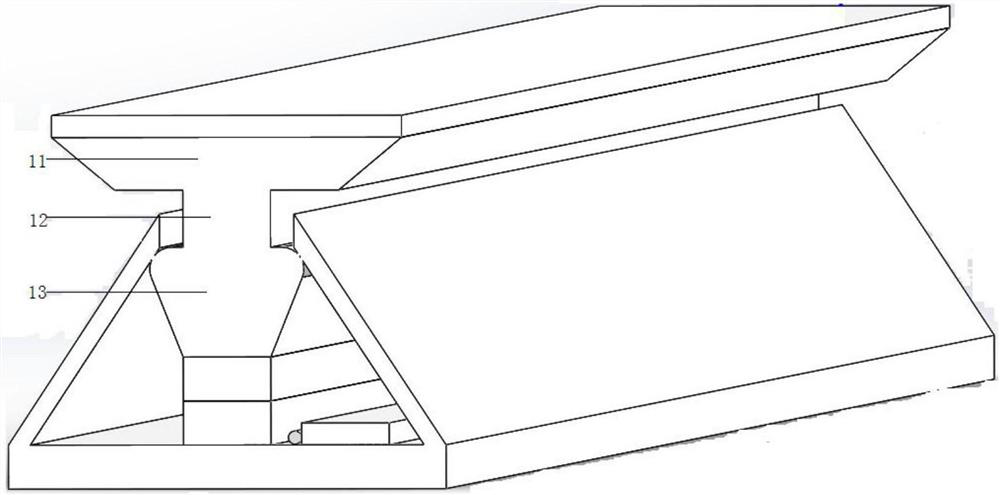

[0055] The weighing piezoelectric sensor also includes a housing 5, and the pressure conducting structure 1, the pre-tensioning splint 2, the quartz piezoelectric crystal 3 and the signal conditioning circuit 4 are sealed by hollow glass microspheres reinforced foam plastic 6. A preset structure, the preset structure is provided in the casing 5 . The hollow glass microsphere reinforced foam plastic 6 is bonded to the pressure conduction structure 1, the pre-tensioning splint 2, the quartz piezoelectric crystal 3 and the signal conditioning circuit 4, and is formed into a square shape, and finally put into the housing 5. The material is elastic and light in weight. The structure can eliminate lateral vibration to a certain extent without affecting the vertical force measurement of the sensor. The shell 5 has various lengths, such as 1000...

Embodiment 3

[0061] Embodiment 3 of the present invention provides another preferred embodiment of the weighing piezoelectric sensor of the present invention.

[0062] The thickness of the surface layer 7 is 5mm, the width is 80mm, and the thickness of the AB glue is 1mm; the height of the two quartz piezoelectric crystals 3 is 10mm, the width is 20mm, and the length is 200mm; The height of the bottom plate 21 is 10mm, the width is 100mm, and the length is 200mm; the width of the circuit board of the signal conditioning circuit 4 is 20mm, the diameter of the conduit 7 is 3mm, the height of the shell 5 is 88mm, and the width of the shell 5 is 106mm .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com