Bolt tightening mechanism and battery pack mounting bracket

A technology for mounting brackets and battery packs, which is used in transportation and packaging, electric power devices, battery/battery traction, etc., which can solve the problems that multiple tightening shafts cannot be operated at the same time, speed up battery replacement time, and high cost of tightening shafts. The effect of shortening battery replacement time, improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, features and effects of the bolt tightening mechanism proposed according to the present invention will be described in detail below with reference to the drawings and preferred embodiments. As after.

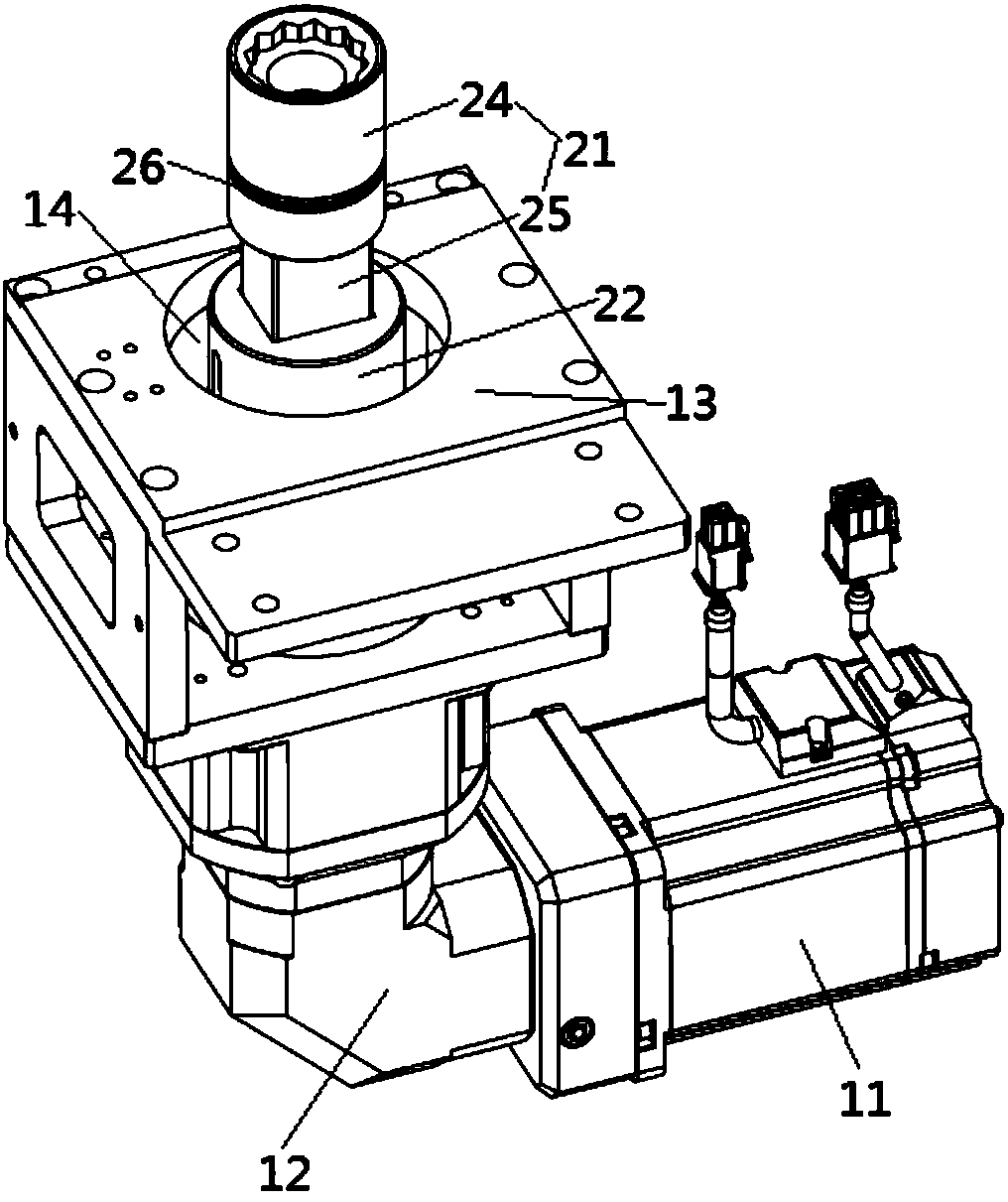

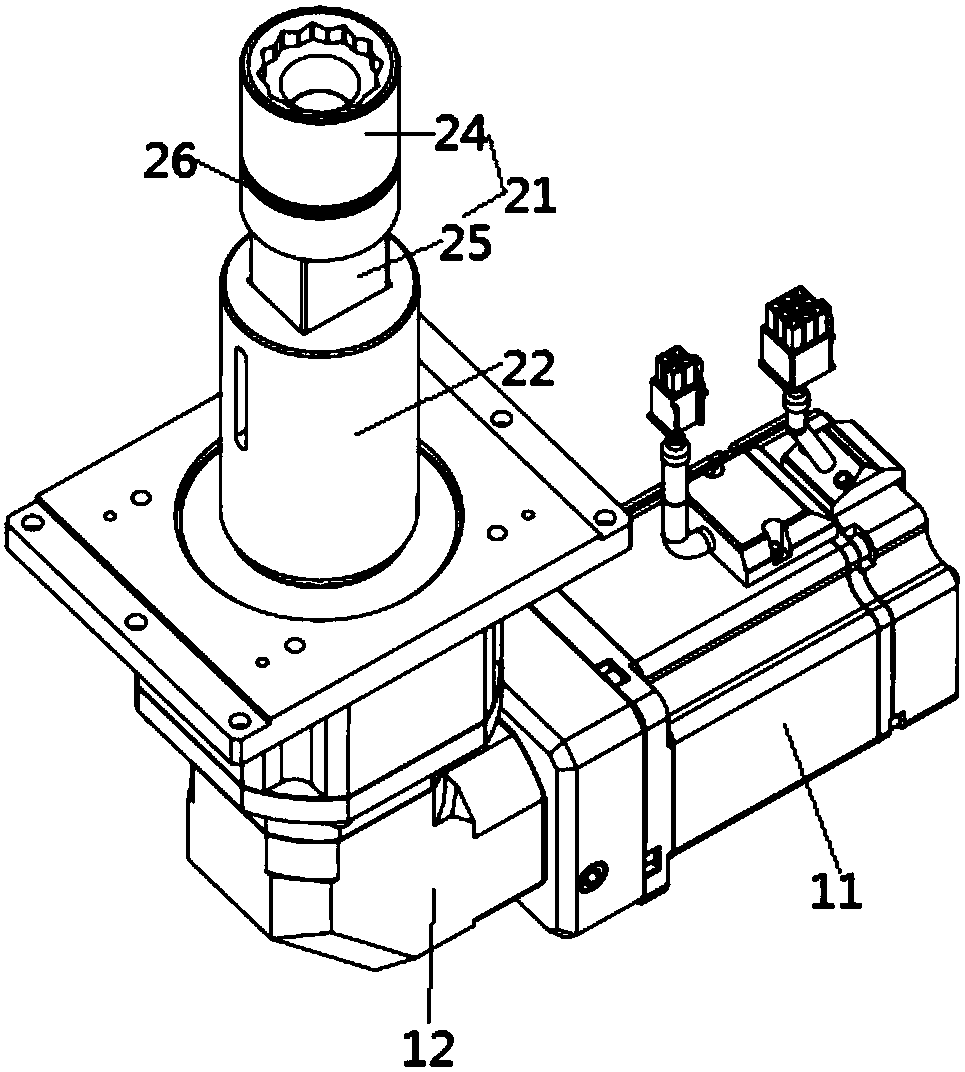

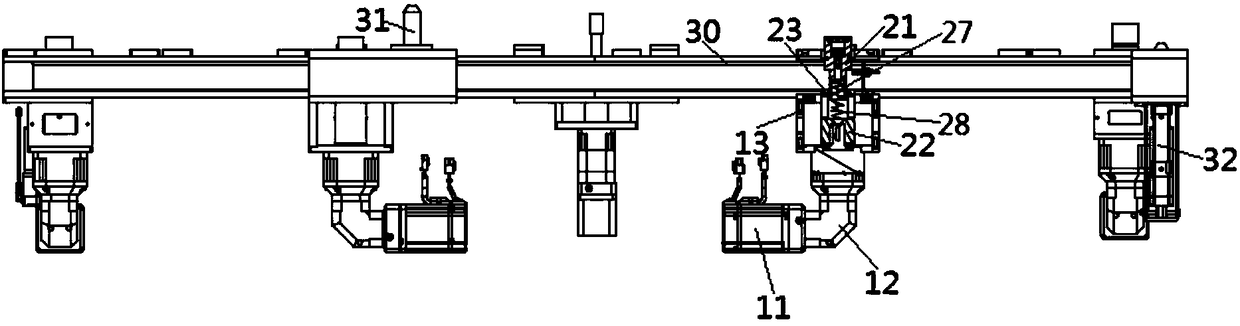

[0040] See figure 1 , figure 2 , image 3 The bolt tightening mechanism of the present invention includes a motor 11, a right-angle reducer 12, a first sleeve 21, and a second sleeve 22. The output shaft of the motor 11 is connected to the input shaft of the right-angle reducer 12, and one end of the first sleeve 21 is connected to the second sleeve. The sleeves 22 are sleeved with each other. The other end of the first sleeve 21 is provided with internal threads for sleeves on the bolts to be screwed. The other end of the second sleeve 22 is fixed on the output shaft of the right-angle reducer 12. The sleeve 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com