A steel pipe rounding and butt joint tooling

A steel pipe and rounding technology, applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve problems such as inability to guarantee concentricity, and achieve the effect of solving low assembly efficiency, improving efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

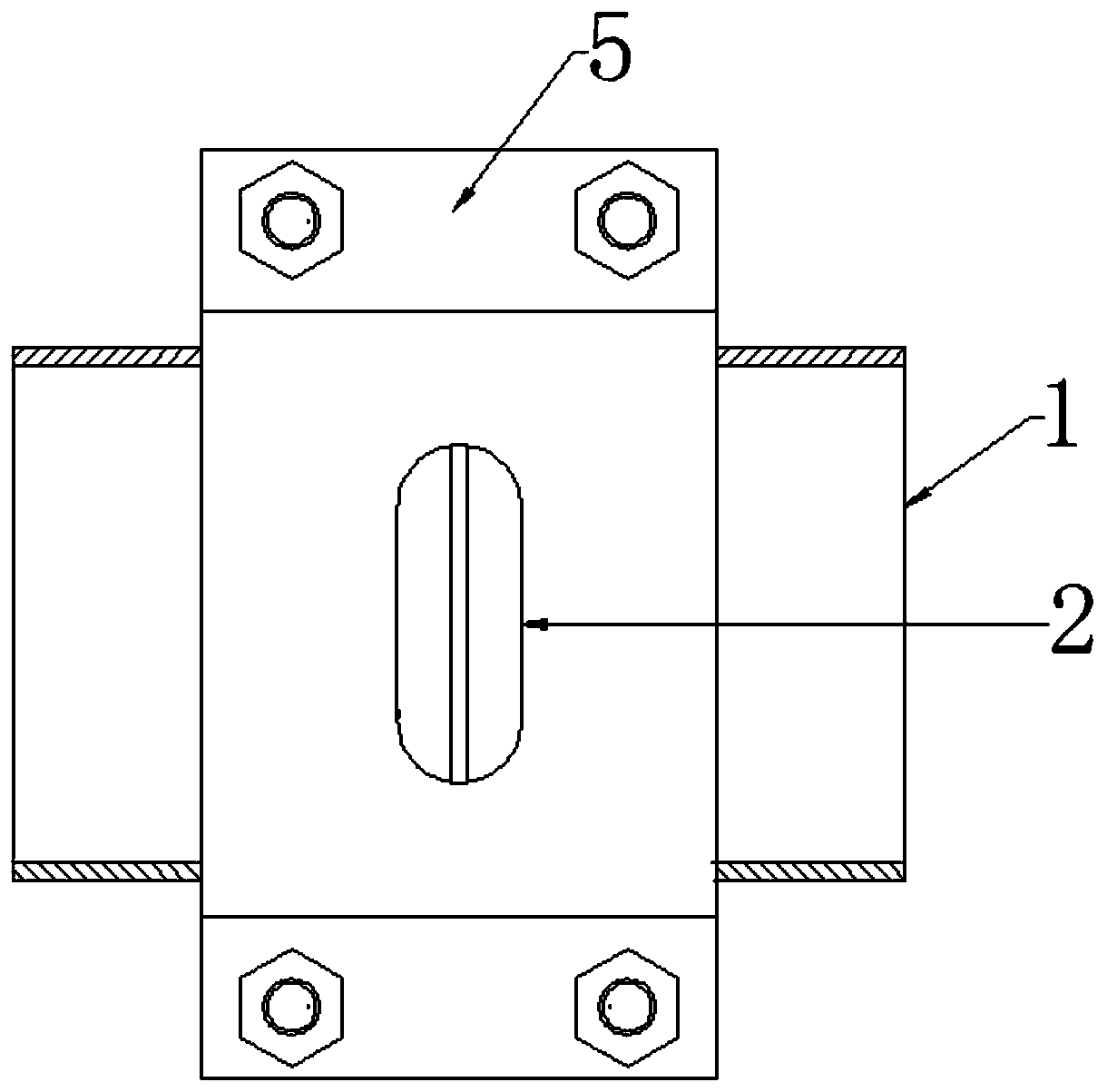

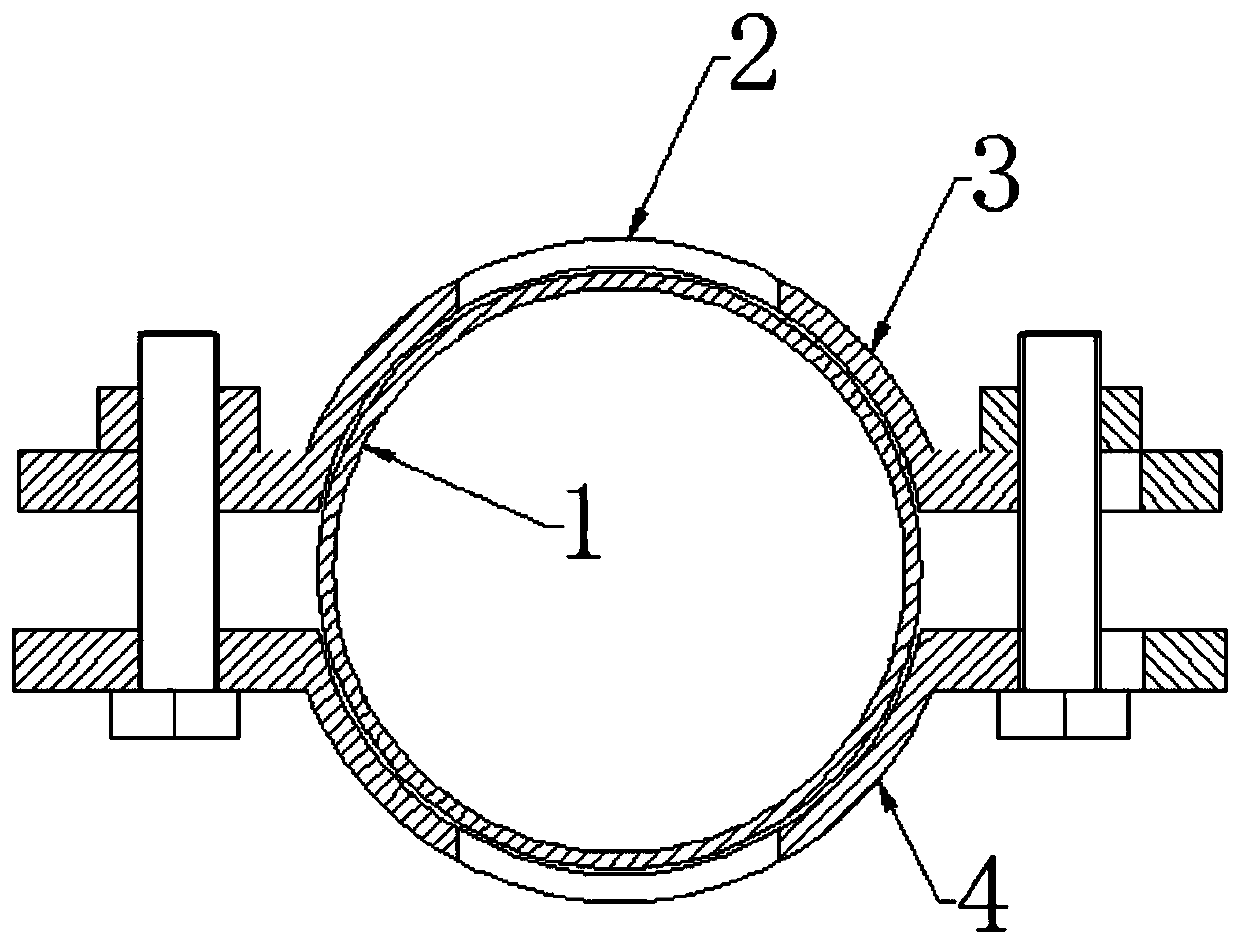

[0023] Such as figure 1 , 2 As shown, the present invention is a steel pipe rounding and docking tool, including a first half ring 3, a second half ring 4, an ear plate 5 and a locking member, and the two ends of the first half ring and the second half ring are connected to the ear plate 5, the ear plate is bent outward, the first half ring and the second half ring are matched with the outer wall of the steel pipe 1, and the first strip hole 2 and the first strip hole 2 are opened on the first half ring and the second half ring respectively The second strip-shaped hole, the length direction of the first strip-shaped hole and the second strip-shaped hole is perpendicular to the axial direction of the steel pipe, and the first half-ring and the second half-ring pass through the screw holes and the Bolted connections engage.

Embodiment 2

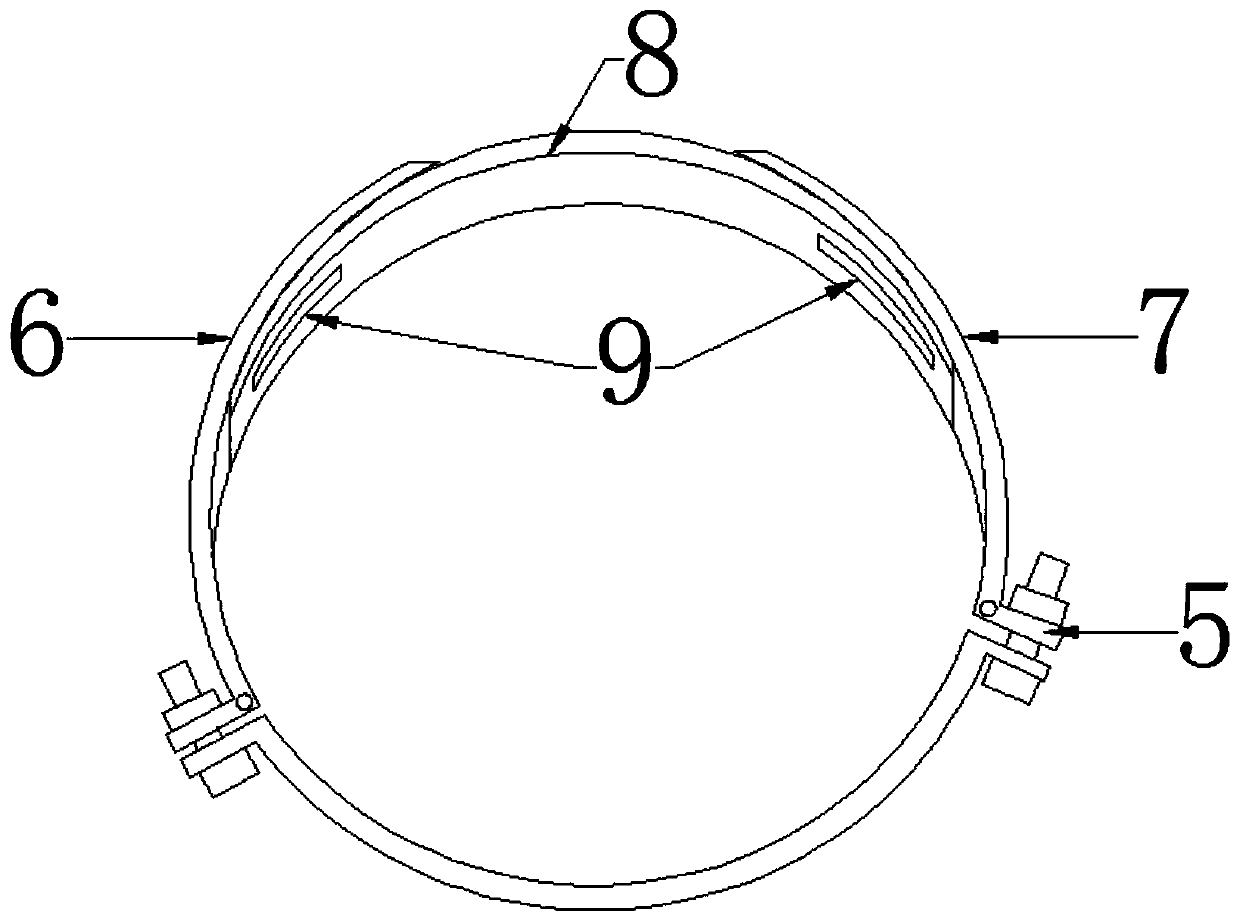

[0025] Such as image 3 , 4 As shown, the present invention is a steel pipe rounding and docking tooling, comprising a first half ring, a second half ring, lugs and a locking member, the two ends of the first half ring and the second half ring are connected to lugs, so The ear plate is bent outward, the first half ring and the second half ring are matched with the outer wall of the steel pipe, and the first and second half rings are respectively provided with a first strip-shaped hole and a second strip-shaped hole, The length direction of the first strip-shaped hole and the second strip-shaped hole is perpendicular to the axial direction of the steel pipe, and the first half-ring and the second half-ring are entwined through screw holes and bolts provided on the lug plate.

[0026] The first half-ring is divided into a first left half-ring 6 and a first right half-ring 7, the ends of the first left half-ring and the first right half-ring are respectively hinged with the ear ...

Embodiment 3

[0031] Such as Figure 5 As shown, the difference between Embodiment 3 and Embodiment 1 is that the tooling also includes an inner strut, and the top end of the inner strut is provided with an arc-shaped plate 16, and the outer surface of the arc-shaped plate conflicts with the inner wall of the steel pipe; The strut includes a first support rod 14, a second support rod 15 and a connecting cylinder 17, the connecting cylinder is provided with an internal thread, the end of the first supporting rod away from the arc-shaped plate is connected to the connecting cylinder 17, and the second support rod is far away from the arc-shaped plate One end of the connecting cylinder is provided with an external thread suitable for the inner wall of the connecting cylinder, and is threadedly connected with the connecting cylinder.

[0032] A hand wheel can be arranged on the outer wall of the connecting cylinder, and when the support rod is adjusted, turning the hand wheel can save labor.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com