A loading method for flap loads in full-scale fatigue tests

A technology of fatigue test and fatigue load, applied in the field of fatigue test, to achieve the effect of optimal application scheme, less number of actuators, and convenient computer automatic iterative calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

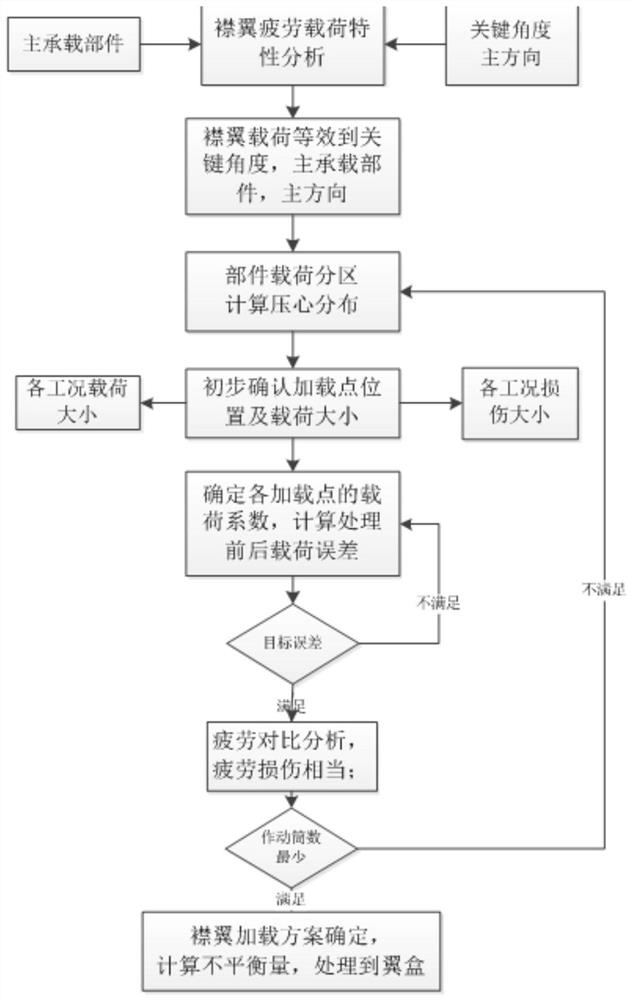

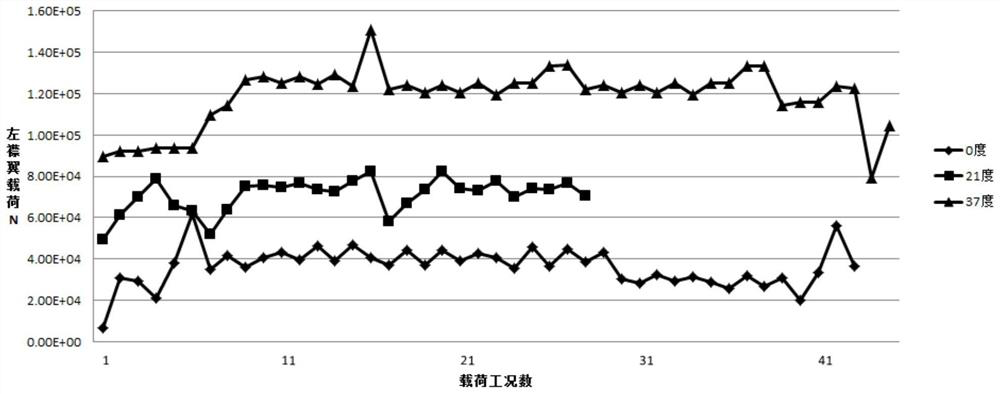

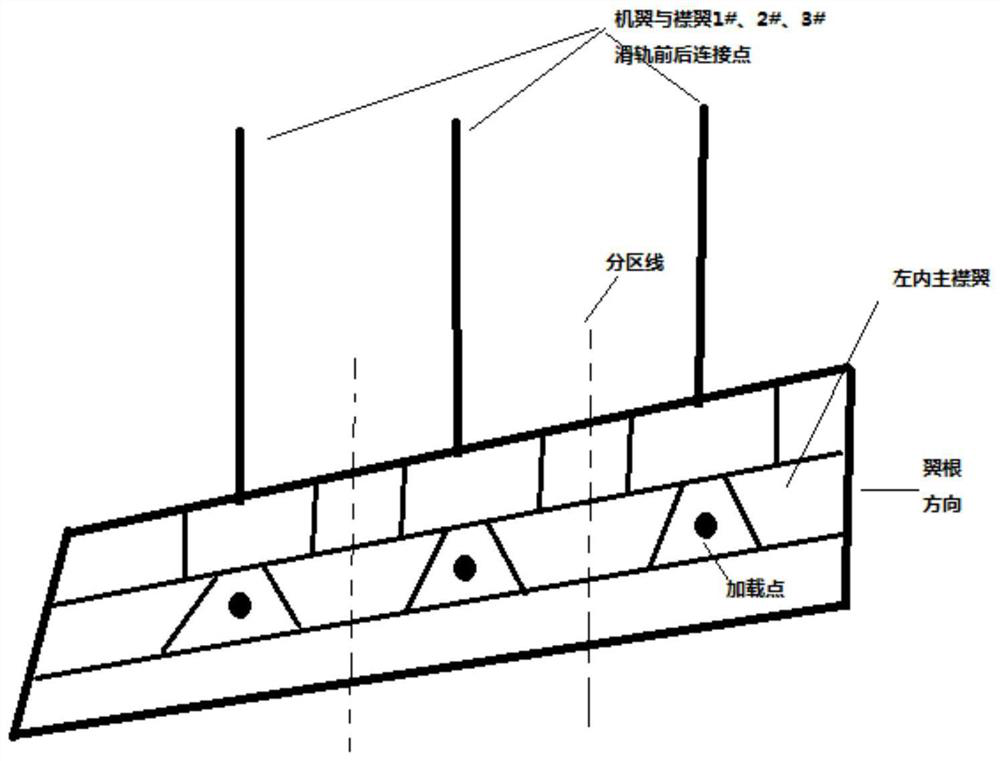

[0027] The full-scale fatigue test flap load loading method of the present invention is from the fatigue test technical field, and according to the force transmission characteristics of the three-slot flap, the flap fatigue loads under various angle states of multiple components are all processed to the critical angle θ , the main bearing part, applied in the main direction. In addition, according to the distributed load characteristics and structural characteristics of the main load-bearing parts, the divisional processing is carried out. According to the two principles of the design state of the connection point of the flap and the wing and the test state, the main direction load error is not greater than the target error and the fatigue damage of the assessment part is equivalent. Through iterative calculation , on the basis of ensuring the accuracy of fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com