Tile cement smearing equipment for building decoration

A ceramic tile and cement technology, applied in construction, building construction, etc., can solve problems such as time-consuming, complicated work process, cement waste, etc., and achieve the effect of preventing cement blockage and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

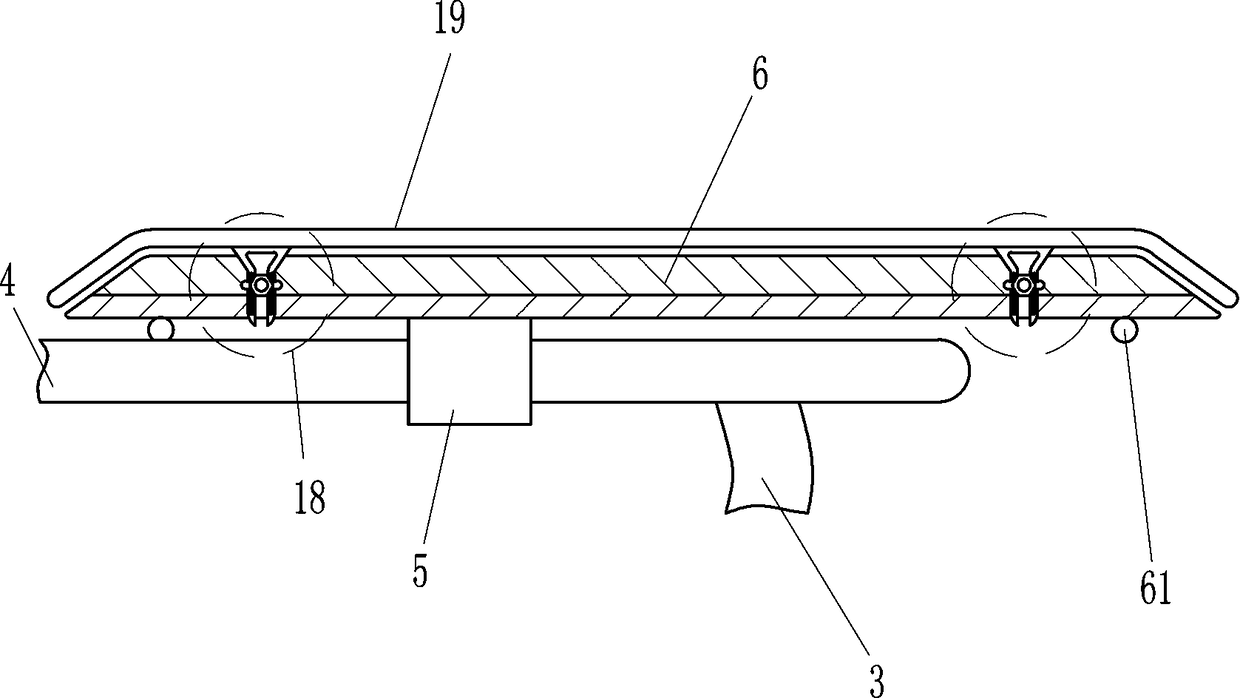

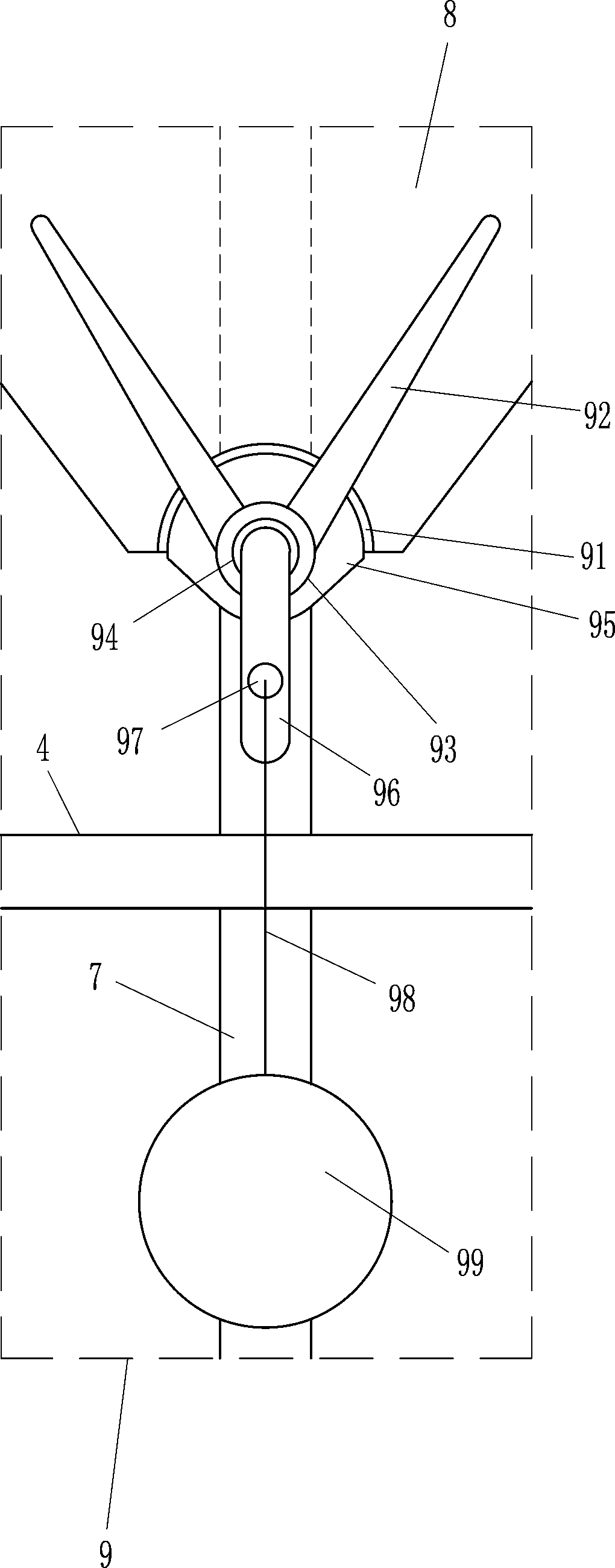

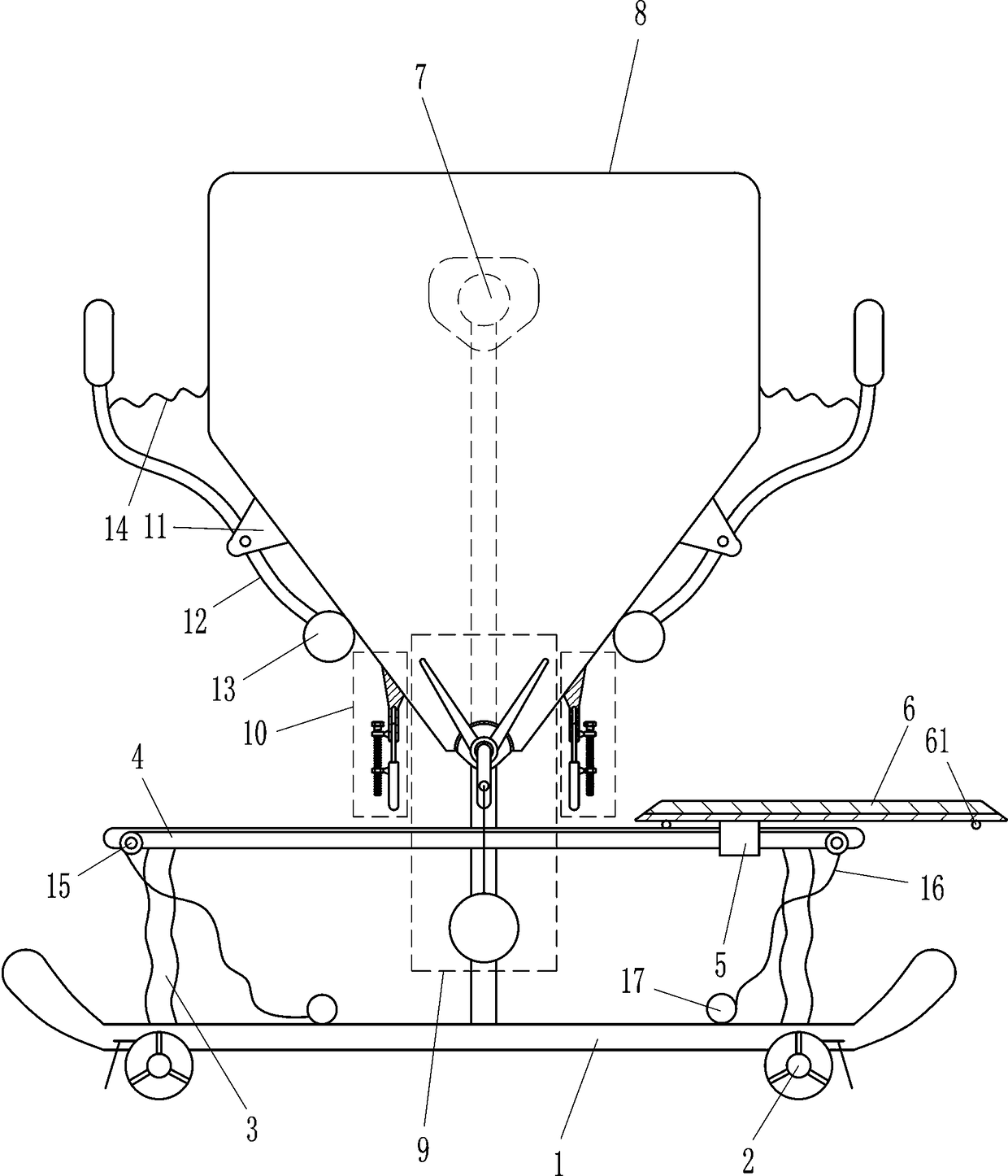

[0025] A kind of tile cement smearing equipment for building decoration, such as Figure 1-5 As shown, it includes base plate 1, wheel 2, first pole 3, guide rod 4, guide sleeve 5, L-shaped plate 6, connecting rod 61, L-shaped pole 7, storage hopper 8, unloading device 9 and pushing Flat device 10, bottom plate 1 is provided with wheels 2 on the left, right, front, and rear sides, first poles 3 are provided on the top, left, and right sides, front and rear of base plate 1, and two first poles 3 on the front and two on the top and rear The top of the first pole 3 is provided with a guide rod 4, and the guide rod 4 is slidably provided with a guide sleeve 5, and the tops of the front and rear guide sleeves 5 are all provided with an L-shaped plate 6, between the front and rear two square L-shaped plates 6 bottoms A connecting rod 61 is provided, an L-shaped strut 7 is arranged in the middle of the top of the bottom plate 1, and the L-shaped strut 7 is located between the front a...

Embodiment 2

[0027]A kind of tile cement smearing equipment for building decoration, such as Figure 1-5 As shown, it includes base plate 1, wheel 2, first pole 3, guide rod 4, guide sleeve 5, L-shaped plate 6, connecting rod 61, L-shaped pole 7, storage hopper 8, unloading device 9 and pushing Flat device 10, bottom plate 1 is provided with wheels 2 on the left, right, front, and rear sides, first poles 3 are provided on the top, left, and right sides, front and rear of base plate 1, and two first poles 3 on the front and two on the top and rear The top of the first pole 3 is provided with a guide rod 4, and the guide rod 4 is slidably provided with a guide sleeve 5, and the tops of the front and rear guide sleeves 5 are all provided with an L-shaped plate 6, between the front and rear two square L-shaped plates 6 bottoms A connecting rod 61 is provided, an L-shaped strut 7 is arranged in the middle of the top of the bottom plate 1, and the L-shaped strut 7 is located between the front an...

Embodiment 3

[0030] A kind of tile cement smearing equipment for building decoration, such as Figure 1-5 As shown, it includes base plate 1, wheel 2, first pole 3, guide rod 4, guide sleeve 5, L-shaped plate 6, connecting rod 61, L-shaped pole 7, storage hopper 8, unloading device 9 and pushing Flat device 10, bottom plate 1 is provided with wheels 2 on the left, right, front, and rear sides, first poles 3 are provided on the top, left, and right sides, front and rear of base plate 1, and two first poles 3 on the front and two on the top and rear The top of the first pole 3 is provided with a guide rod 4, and the guide rod 4 is slidably provided with a guide sleeve 5, and the tops of the front and rear guide sleeves 5 are all provided with an L-shaped plate 6, between the front and rear two square L-shaped plates 6 bottoms A connecting rod 61 is provided, an L-shaped strut 7 is arranged in the middle of the top of the bottom plate 1, and the L-shaped strut 7 is located between the front a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com