Full-computer hosiery knitter

A sock knitting machine and full computer technology, applied in knitting, weft knitting, mechanical cleaning, etc., can solve the problems of simple functions, low production efficiency, and low-grade products, and achieve easy tension, easy replacement, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

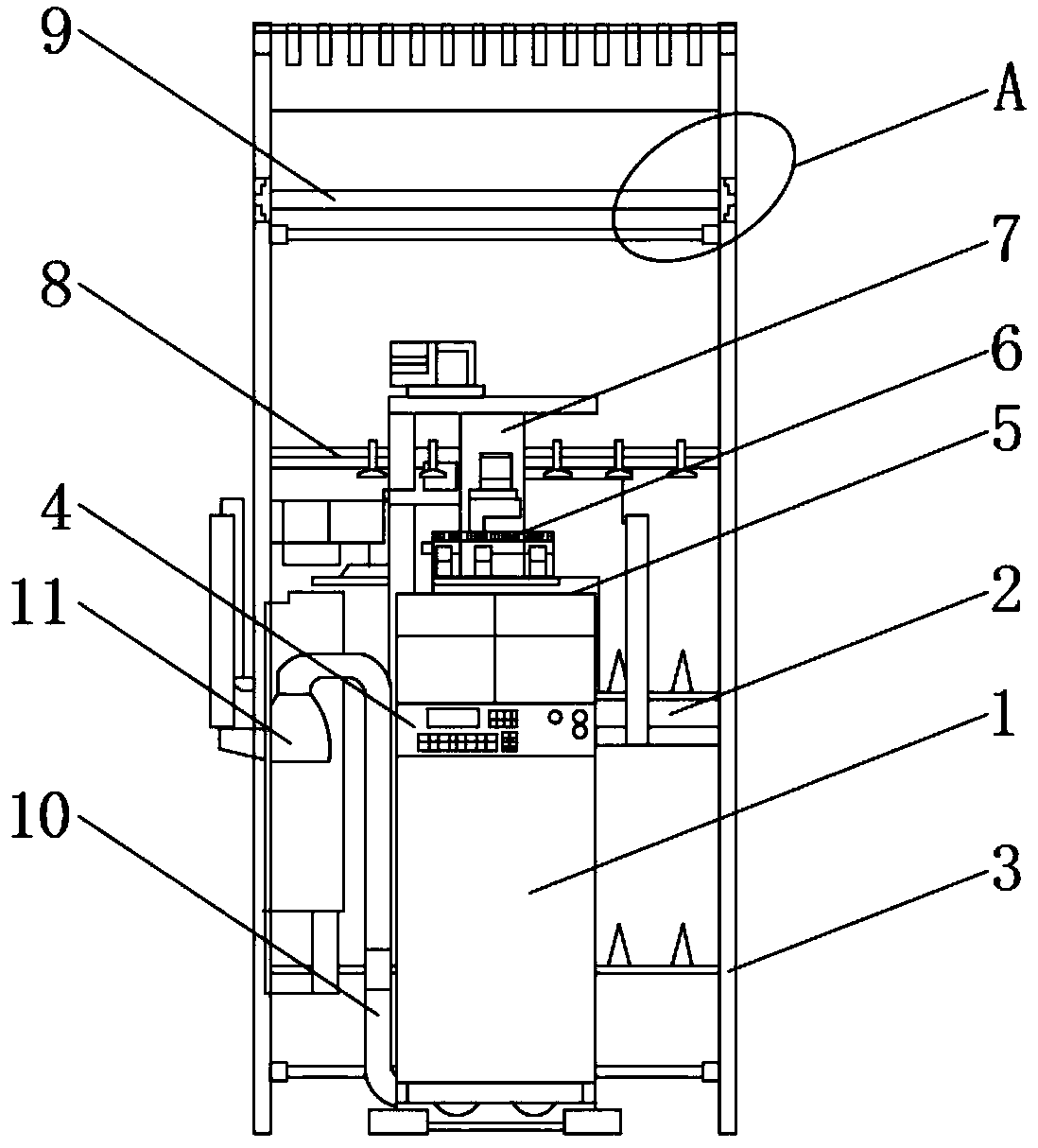

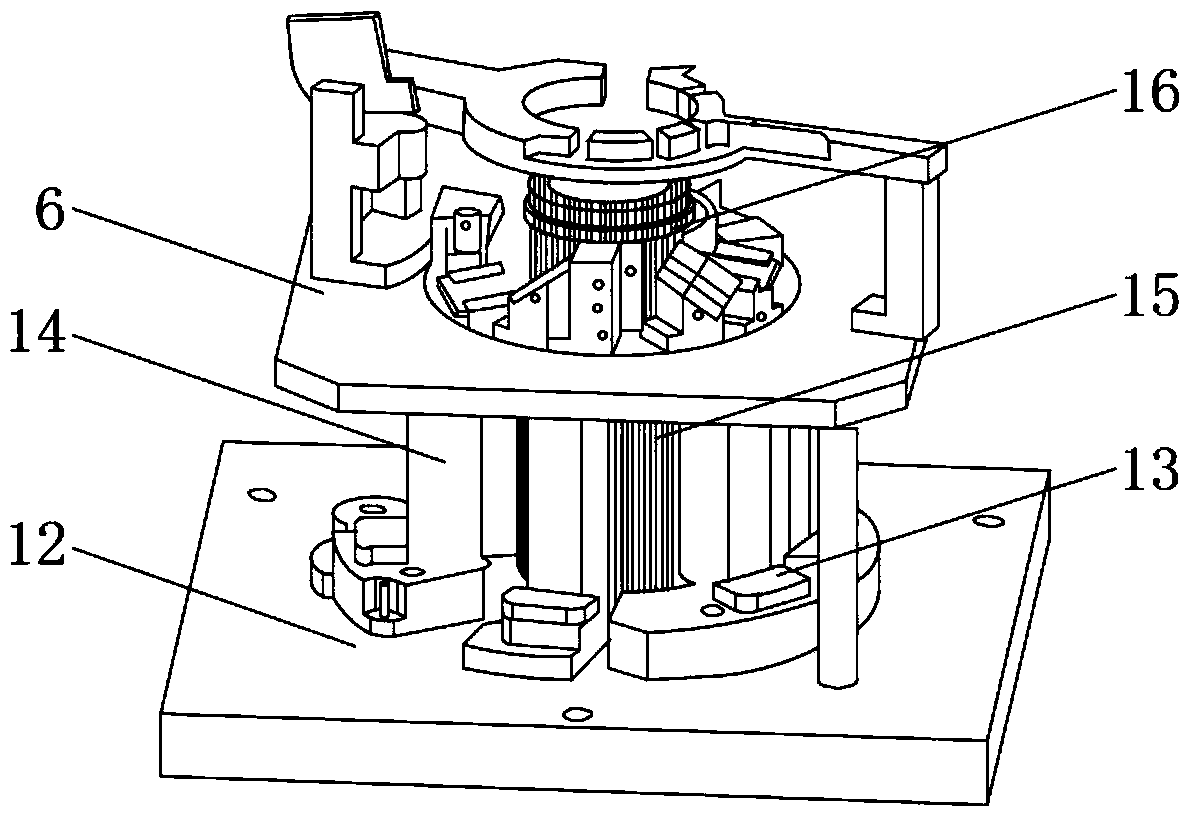

Embodiment 1

[0021] Such as Figure 1-4 As shown, a fully computerized hosiery machine includes an electric control box 1, the rear end of the electric control box 1 is fixedly installed with a receiving plate 2, both ends of the receiving plate 2 are fixedly installed with brackets 3, and the front end of the electric control box 1 A control panel 4 is fixedly installed on the outer surface, a workbench 5 is fixedly installed on the upper end of the electric control box 1, a loop forming mechanism 6 is fixedly installed on the upper end of the workbench 5, and an auxiliary loop forming mechanism 7 is arranged on the upper end of the loop forming mechanism 6. A yarn feeding mechanism 8 is fixedly installed inside the 3, and the yarn feeding mechanism 8 is located at the upper end of the knitting mechanism 6, and the upper end of the support 3 is fixedly installed with a thread-carrying rod 9 inside, and the thread-carrying rod 9 is located at the upper end of the yarn feeding mechanism 8, ...

Embodiment 2

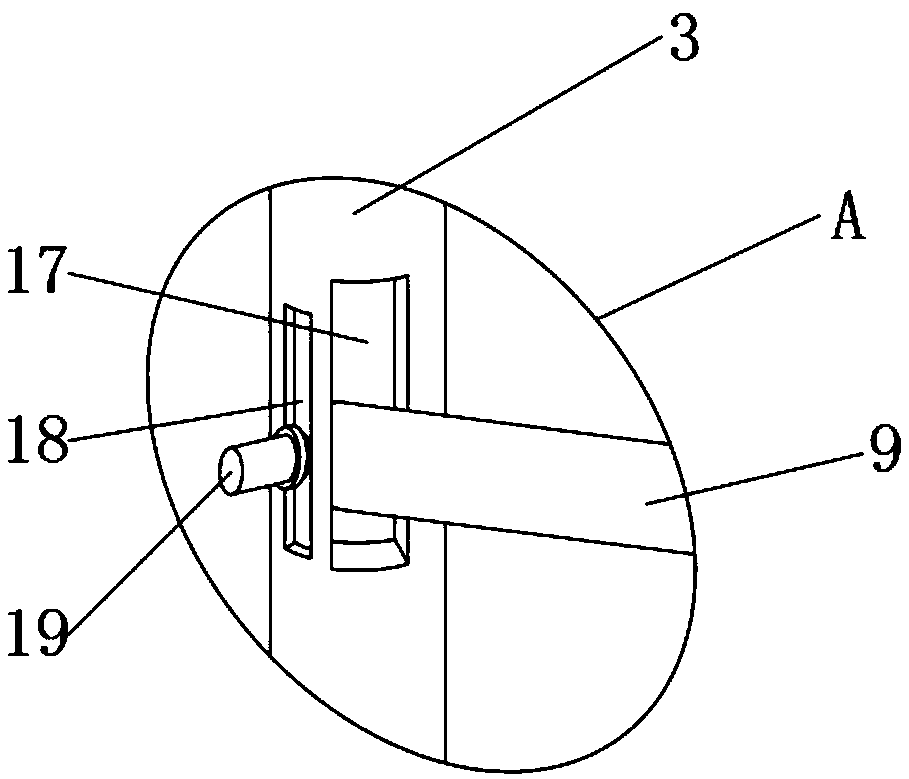

[0023] Such as Figure 1-4 As shown, the inner wall of the adjustment hole 18 is provided with an internal thread, and the outer circumferential surface of the locking rod 19 is provided with an external thread, and the internal thread and the external thread are threaded, the adjustment hole 18 is movably connected with the locking rod 19, and the installation sleeve 20 is connected with the sleeve The filter screen 21 is threadedly connected, and the installation sleeve 20 is flexibly connected with the cover filter screen 21. The bottom end of the cover filter screen 21 is provided with a sock leakage hole, and the inner wall of the cover filter screen 21 is provided with a velvet brush. The velvet brush can clean and filter the knitted socks, filter out the fluff threads on the surface, etc., and is easy to replace. The auxiliary loop forming mechanism 7 is movably connected with the loop forming mechanism 6, and the auxiliary loop forming mechanism 7 is located in the yarn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com