Synthetic method of 2,6-dihalopyridine-3-carboxylic acid

A technology of dihalopyridine and a synthesis method, which is applied in the synthesis of 2,6-dihalopyridine-3-carboxylic acid and the synthesis of pyridine compounds, can solve the problems of low yield and the like, and achieves good operation reproducibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

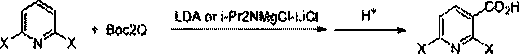

Method used

Image

Examples

Embodiment 1

[0026] Under the protection of nitrogen, 2,6-difluoropyridine (11.5 g, 0.1 mol), Boc2O (26.0 g, 0.12 mol) and 130 mL of tetrahydrofuran were stirred until completely dissolved, and the ice-salt bath was lowered to -15 ° C, and the drop Add a pre-prepared 1M LDA tetrahydrofuran solution (0.13 mol), and control the temperature not to exceed -10°C during the entire dropwise addition. After the dropwise addition, keep stirring for 2-3 hours, then naturally rise to room temperature and stir to react overnight, and TLC detects that there is basically no remaining raw material.

[0027] Lower the reaction solution to 0°C again, add 15% aqueous hydrochloric acid dropwise to pH = 1-2 (note that the acidity adjustment should not be too strong, when the acidic hydrolysis is not controlled, a small amount of 2-hydroxy-6-fluoro-pyridine- 3-carboxylic acid). During the dropwise addition process, heat is obviously released, control the temperature not to exceed 30°C, raise the temperature t...

Embodiment 2

[0029] Under the protection of nitrogen, 2,6-dichloropyridine (14.8 g, 0.1 mol), Boc2O (26.0 g, 0.12 mol) and 130 mL of tetrahydrofuran were stirred until completely dissolved, and the ice-salt bath was lowered to -15 ° C, and the drop Add the isopropylmagnesium chloride-lithium chloride solution dropwise into the diisopropylamine tetrahydrofuran solution in advance, and prepare a 1M diisopropylamine magnesium chloride-lithium chloride tetrahydrofuran solution (0.15 moles). over -10°C. After the dropwise addition, keep stirring for 2-3 hours, then naturally rise to room temperature and stir to react overnight, and TLC detects that there is basically no remaining raw material.

[0030] The reaction solution was lowered to 0°C again, and 36% aqueous hydrochloric acid was added dropwise until pH=1. During the dropwise addition process, the heat is obviously exothermic, and the temperature should not exceed 30°C. After the dropwise addition, the temperature should be raised to 35...

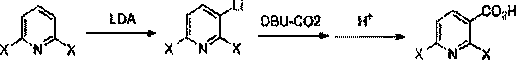

Embodiment 3

[0032] Under the protection of nitrogen, stir 2,6-difluoropyridine (11.5 g, 0.1 mol) and 120 mL of tetrahydrofuran until completely dissolved, then cool down the dry ice / acetone system to -75°C, and start to add the pre-prepared 1M LDA tetrahydrofuran dropwise solution (0.12 moles), the temperature control during the whole dropping process should not exceed -60°C. After the dropwise addition, keep stirring for 1.5 hours, then dissolve the DBU-CO2 complex (0.11mol) in 65mL tetrahydrofuran solution, control the temperature not to exceed -60°C and drop into the reaction solution, keep stirring for 2 hours, and naturally rise to The reaction was stirred at room temperature overnight, and there was almost no remaining raw material as detected by TLC.

[0033] The reaction solution was lowered to 0°C again, and 15% hydrochloric acid aqueous solution was added dropwise to pH=3-5. During the dropwise addition process, the heat is obviously released, and the temperature is controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com