A multi-level sandwich composite structure and an automobile front panel using the structure

A composite structure and sandwich technology, applied in lamination, layered products, lamination devices, etc., can solve the problems of high requirements, inability to block a lot of noise and heat, single function, etc., and achieve the effect of preventing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

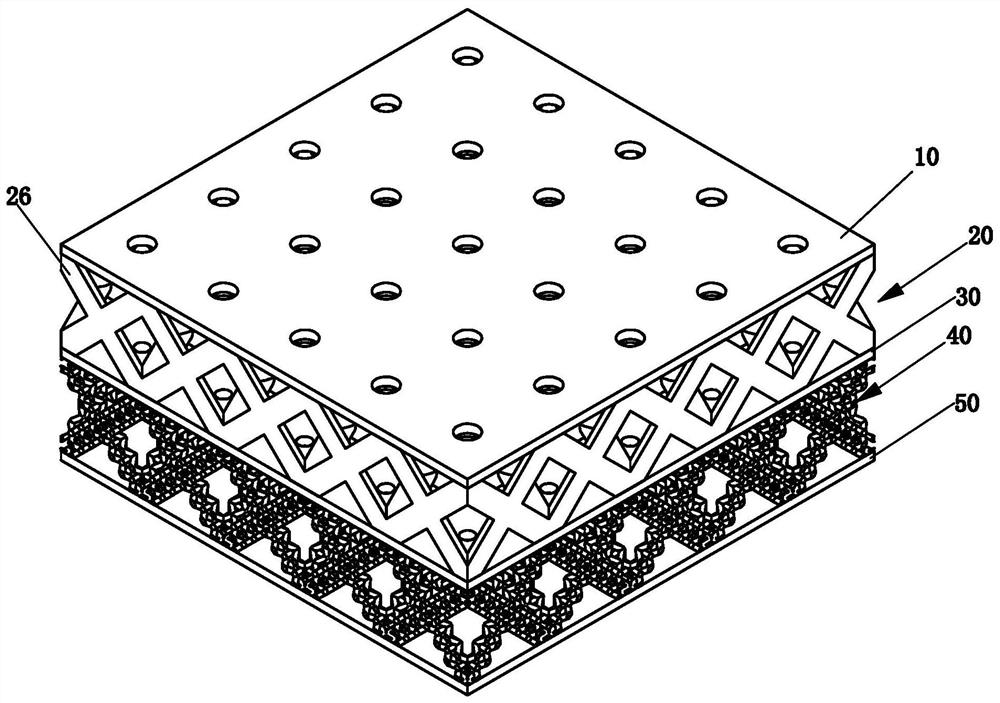

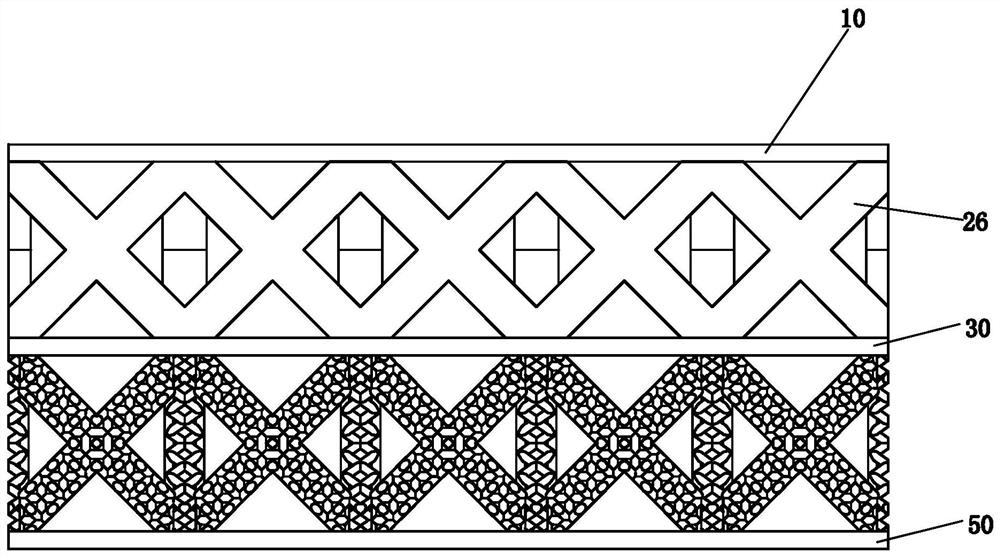

[0038] Please check Figure 1 to Figure 12 , a preferred embodiment of a multi-level sandwich composite structure and an automobile dash panel using the structure, the multi-level sandwich composite structure includes an upper top plate 10, a first sandwich body 20, a middle partition 30 . The second sandwich body 40 and the lower bottom plate 50 .

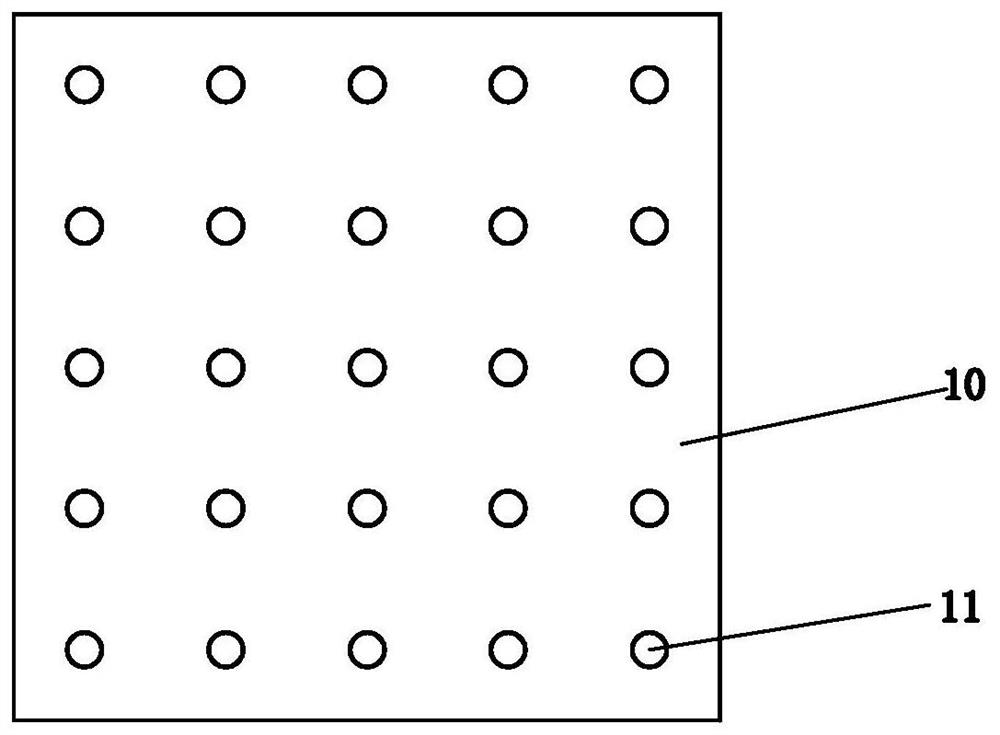

[0039] The upper top plate 10 includes a barrier film layer and an aluminum plate layer arranged up and down. Pressed. The barrier film has a high reflection effect and good barrier effect on heat radiation. It is applied to the front wall of the car, which can effectively isolate the large amount of heat generated by the engine during the driving process of the car, and prevent the large amount of heat and exhaust gas in the engine compartment from entering the car compartment. It will affect the occupants, especially the driver. In addition, it can effectively isolate the heat generated in the engine compartment to prevent the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com