Crystallizing method for unsaturated salt solution on basis of carbon-based material

A carbon-based material and salt solution technology, which is applied in the field of unsaturated salt solution crystallization and can solve problems such as inability to precipitate crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Graphene oxide membranes with filter membrane supports and partially reduced graphene oxide membranes were prepared by suction filtration.

[0037] Take 1mL graphene oxide aqueous solution with a concentration of 5mg / mL, dilute it to 10mL with deionized water, carry out filter membrane suction filtration, and then put it in an oven to dry at 70°C for 8 hours to obtain a graphene oxide membrane supported by a filter membrane. 25 microns thick;

[0038] Preparation of partially reduced graphene oxide: Put the above obtained graphene oxide membrane with filter membrane support into a reaction kettle containing 30mL deionized water for hydrothermal reaction at 180°C to obtain a partially reduced graphene oxide membrane, which The thickness is 25 microns.

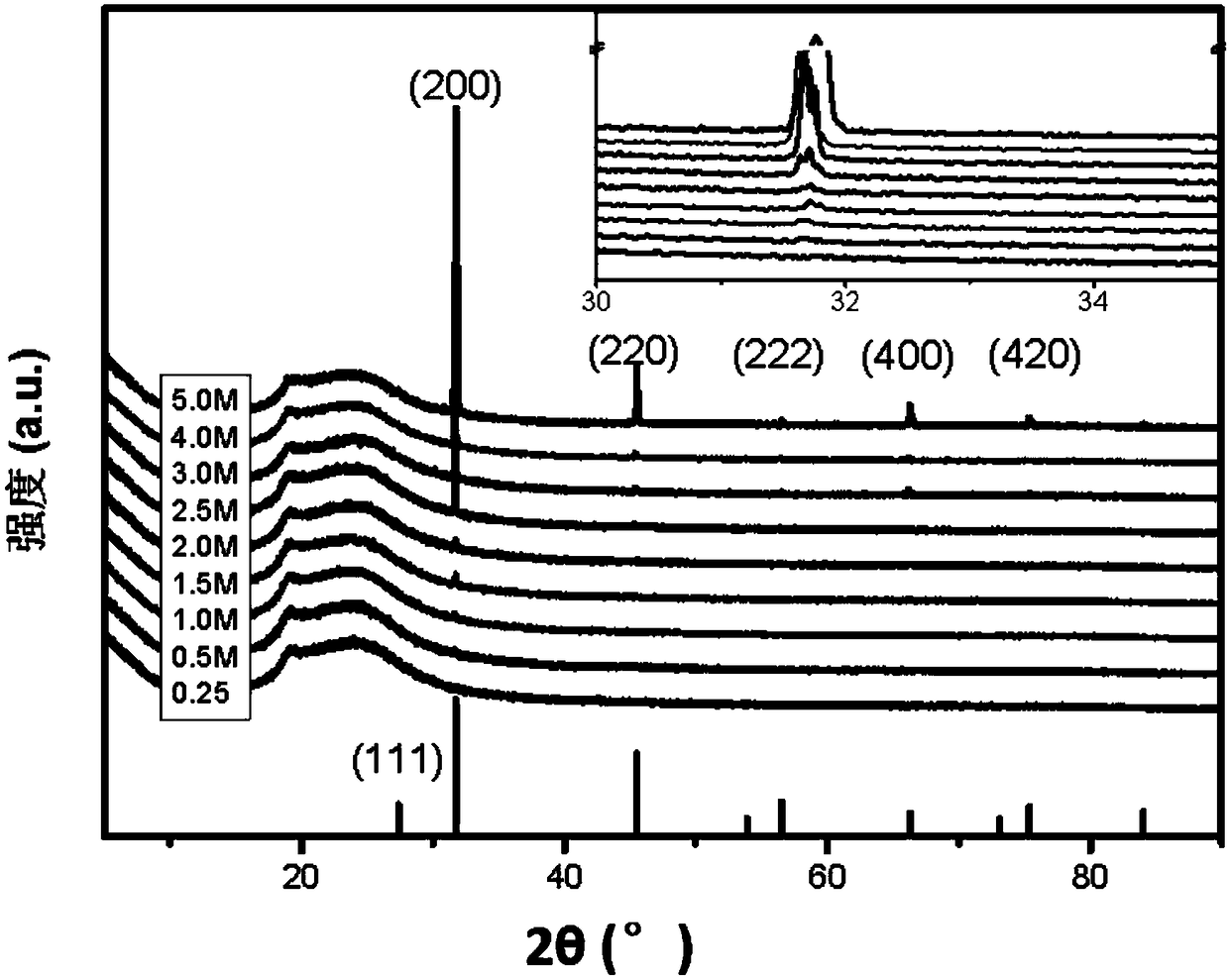

[0039]The graphene oxide membrane with filter membrane support was soaked in the molar concentration of 0.25mol / L, 0.5mol / L, 1.0mol / L, 1.5mol / L, 2.0mol / L, 2.5mol / L, 3.0mol / L L, 4.0mol / L and 5.0mol / L NaCl aqueous solutio...

Embodiment 2

[0042] Freestanding graphene oxide membranes prepared by drop-coating method.

[0043] Take 1 mL of graphene oxide aqueous solution with a concentration of 5 mg / mL and drop-coat it on the surface of smooth hydrophobic paper, and dry it in an oven at 70°C for 8 hours to obtain an independently supported graphene oxide film with a thickness of 100 microns.

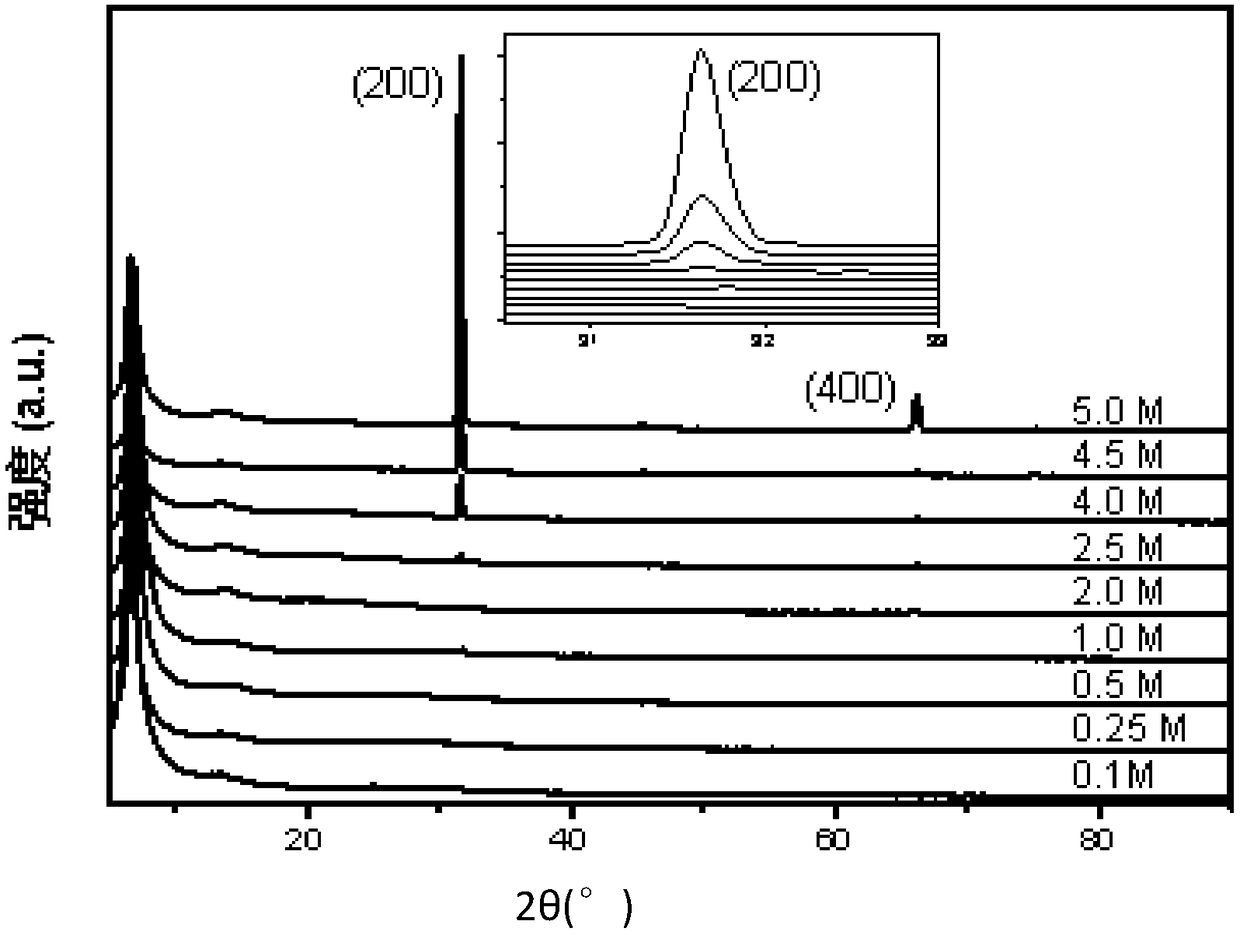

[0044] Soak the independently supported graphene oxide membranes in molar concentrations of 0.1mol / L, 0.25mol / L, 0.5mol / L, 1.0mol / L, 2.0mol / L, 2.5mol / L, 4.0mol / L, 4.5 mol / L and 5.0mol / L NaCl aqueous solution for 0.5 hours, then remove the soaking solution and centrifuge to separate the adsorbed water from the surface of the membrane, take out the wet film and weigh it, then put it in an oven for 6 hours to dry at 60°C, take out the dry film and weigh it.

[0045] Calculate the salt solution, the adsorption amount of salt in the membrane and the salt concentration in the membrane after the independently supported graphene oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com