Boom conveyor

A conveyor and cantilever technology, applied in the field of cantilever conveyors, can solve problems such as complex self-leveling mechanisms, and achieve the effect of avoiding risks, safe and effective loading and unloading operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

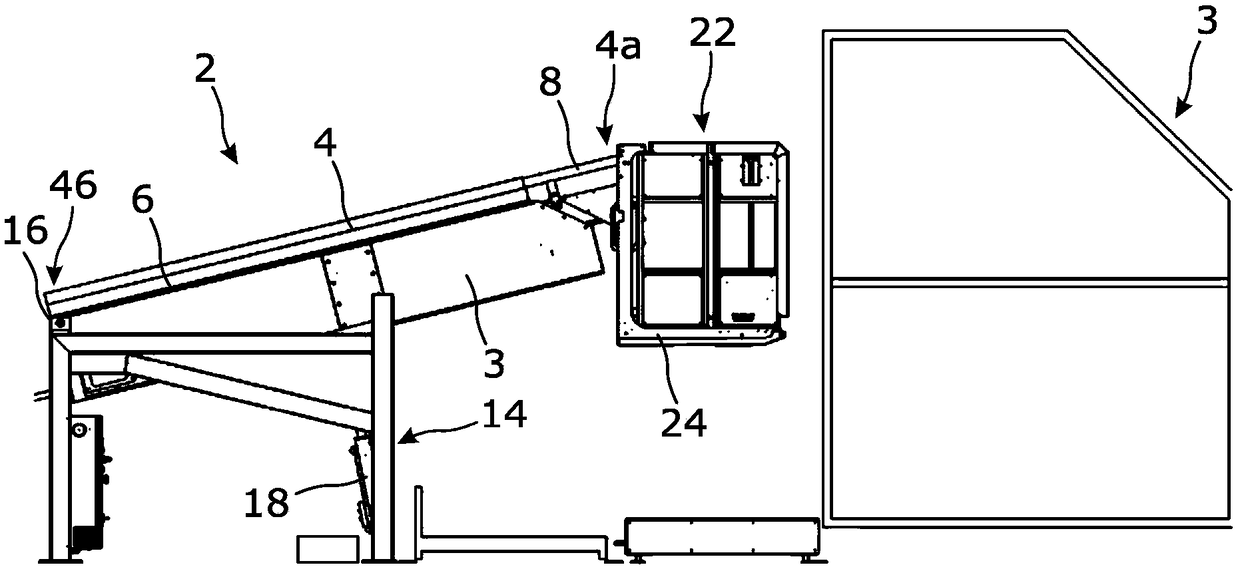

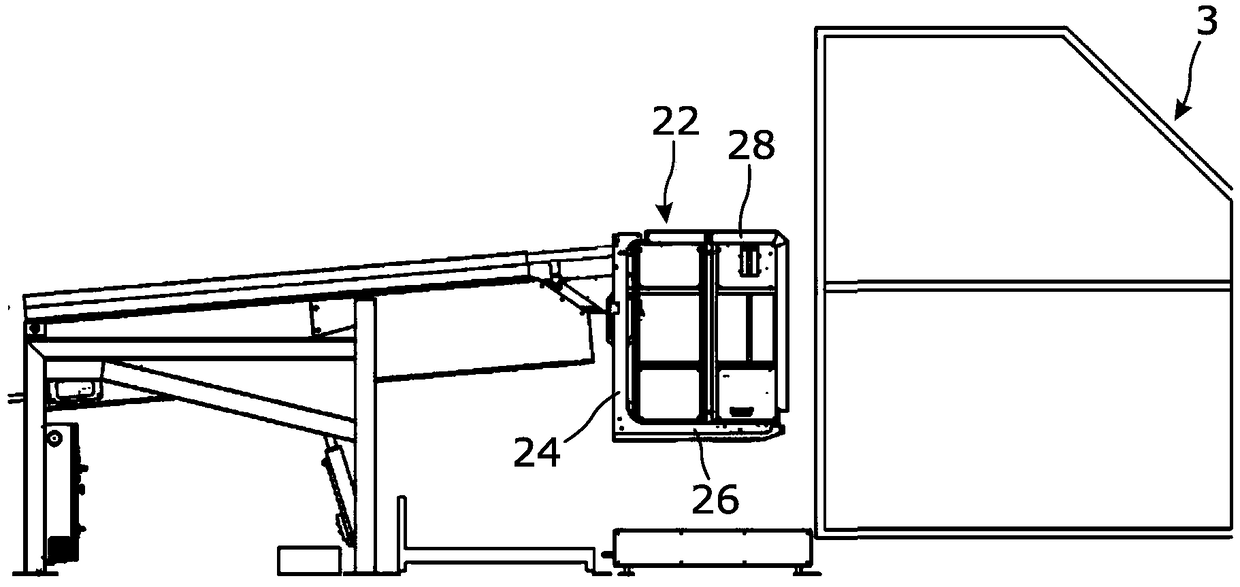

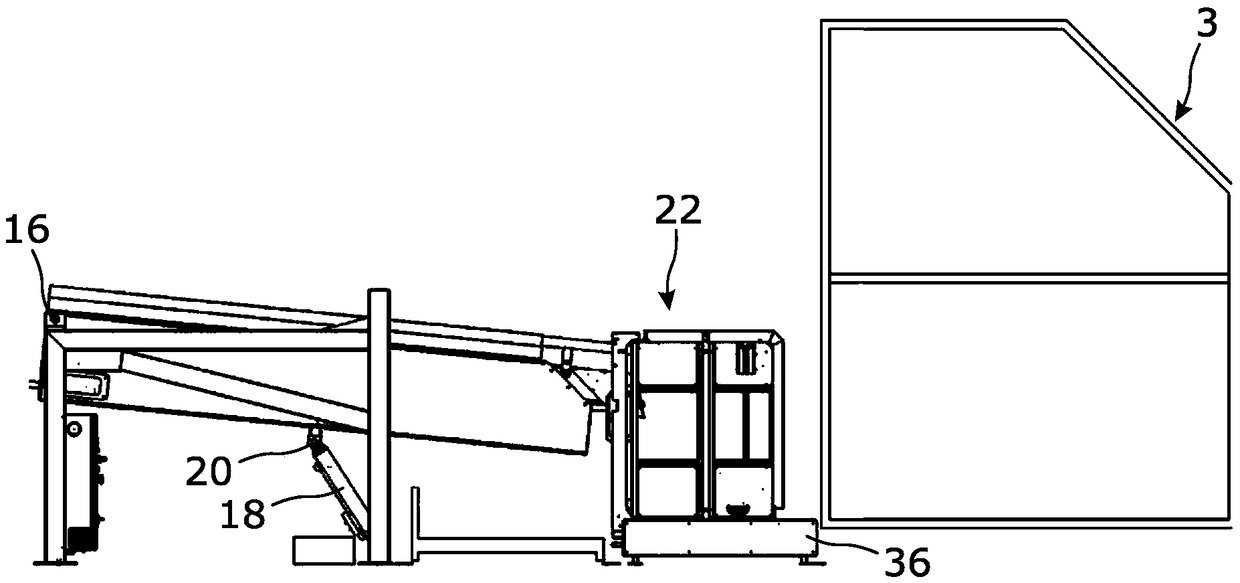

[0048] in the attached Figure 1 to Figure 3 A loading device 2 is shown, which in this embodiment is designed for loading and unloading cargo to and from a conventional unit loading device 3 . The loading apparatus may alternatively be designed for loading and unloading a road vehicle, rail wagon, aircraft or any other cargo container with cargo.

[0049] The loading apparatus 2 includes a boom conveyor 3, which in this embodiment includes a telescopic arm 4 having a rear boom portion 6 and a front boom portion 8, the front boom portion 8 being accessible relative to the rear boom portion 6. Extends telescopically in order to adjust the overall length of the cantilever conveyor 4 . Typically, the cantilever conveyor 3 has a maximum length of about 5.5 meters when fully extended and a minimum length of about 3 meters when fully retracted. However, these dimensions are not limiting; in some applications, the cantilever conveyor can have a length of 15 meters or more when full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com