Instrument and method for rapid analysis of cross-scale inclusions based on photomicrograph matrix

A microphotography and rapid analysis technology, which is applied in the direction of instruments, scientific instruments, and analytical materials, can solve the problems of inability to obtain metallographic information of inclusions in cross-scale samples, time-consuming and labor-intensive processing, and surface distortion, so as to avoid the lack of characterization problems, improving analysis efficiency, and the effects of large scan sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below with reference to the accompanying drawings and an embodiment.

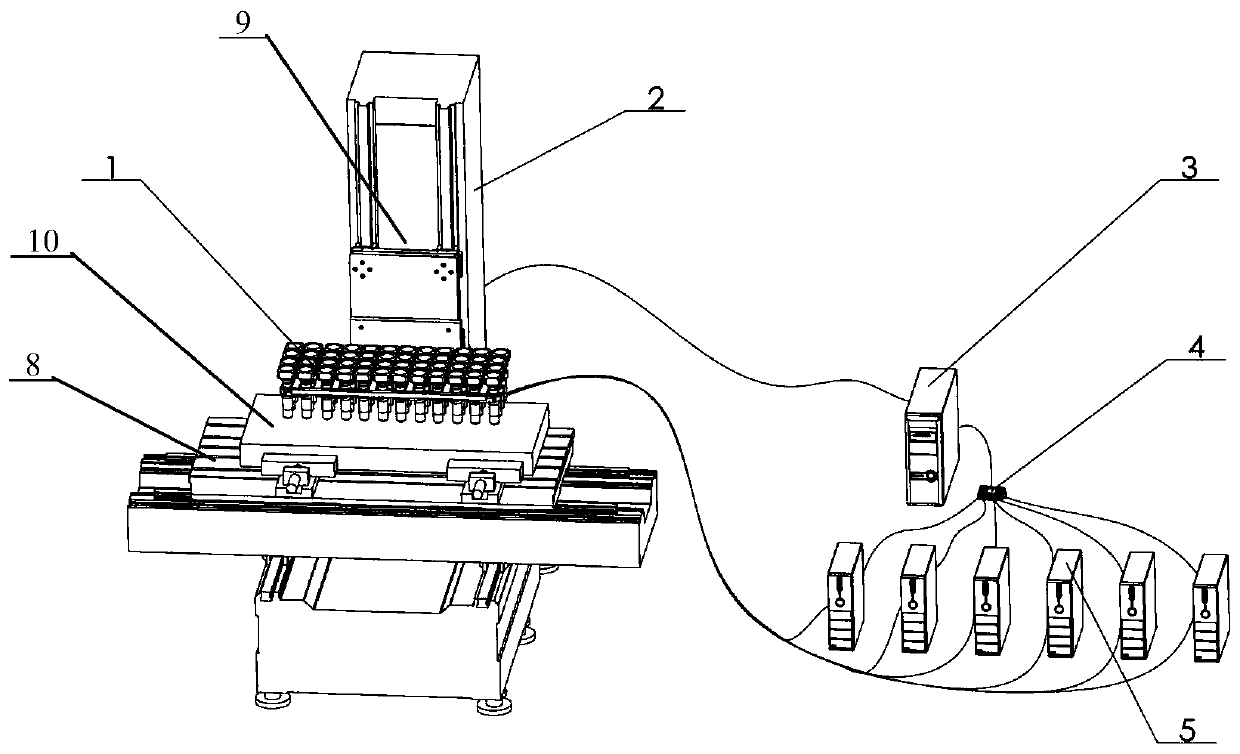

[0053] like figure 1 As shown, the cross-scale inclusion rapid analysis instrument based on the photomicrograph matrix of the present invention includes: a photomicrograph matrix system 1, a high-precision three-dimensional numerical control workbench 2, a calculation work group, and a control and data processing system.

[0054] The high-precision three-dimensional numerical control table 2, which is precisely controlled by PLC and driven by a lead screw, includes a horizontal sample table 8 that is precisely moved in the horizontal X-axis and Y-axis directions for fixing the sample to be tested 10, and a horizontal sample table 8 perpendicular to the X-axis and Y-axis plane. 9 of the Z axis. The displacement accuracy of the high-precision three-dimensional numerical control worktable 2 is micron level.

[0055] The sample to be tested 10 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com