Large-shaft-diameter sliding bearing set tribology performance test stand with adjustable space under movable loads

A technology of sliding bearings and test benches, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of unreasonable loading structure, small adjustment range, and inaccurate simulation of actual working conditions, etc., and achieve the effect of multi-point loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

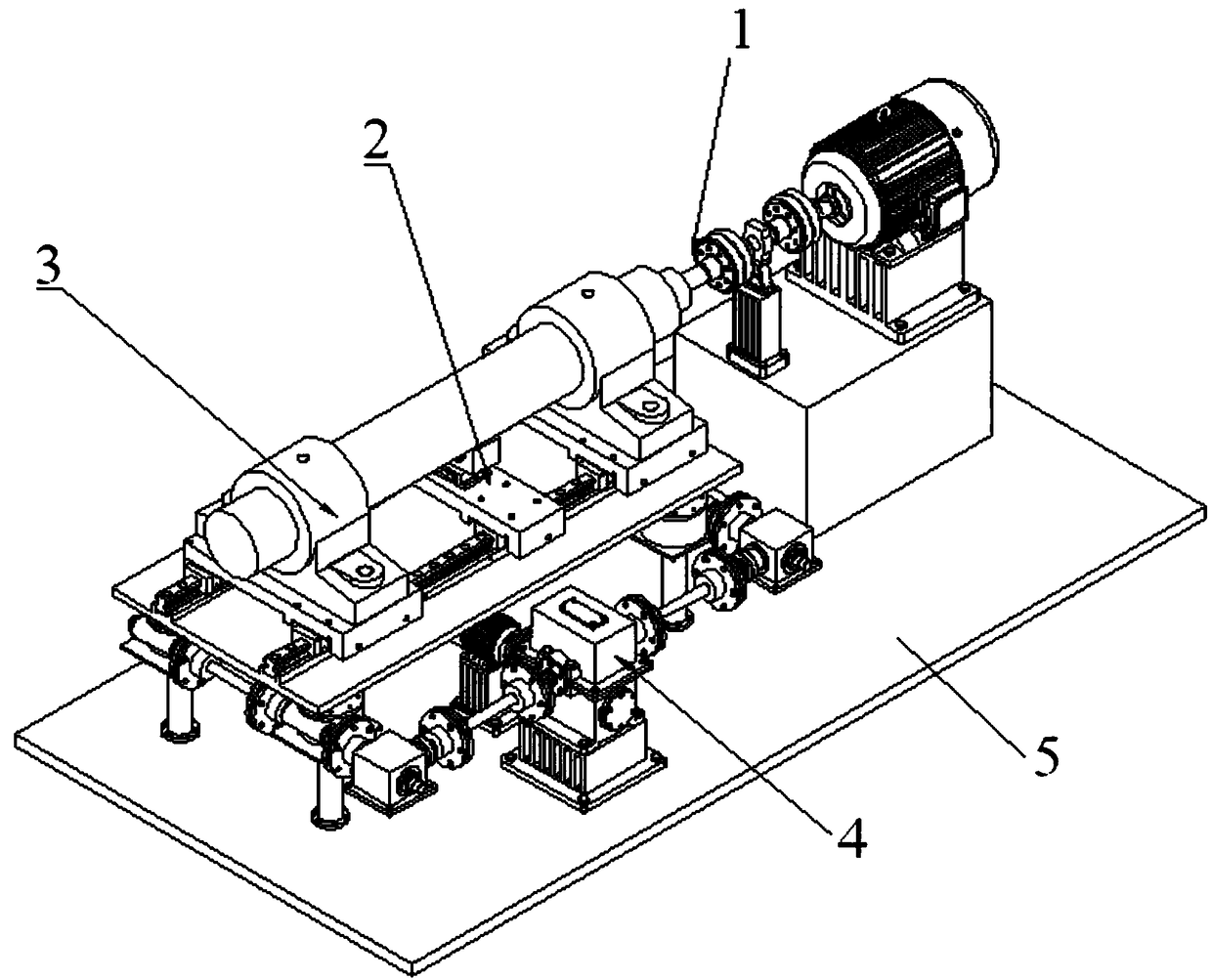

[0037] see figure 1 , including power output device 1, hydraulic loading device 2, dynamic and static pressure bearing auxiliary device 3, test bench liftable support device 4, test bench base 5, test bench liftable support device 4 fixed on the test bench base 5, dynamic and static pressure bearing The auxiliary device 3 is fixed on the liftable support 4 of the test bench, the hydraulic loading device 2 is fixed on the dynamic and static pressure bearing auxiliary device 3, and the power output system 1 is fixed on the boss of the test bench base 5;

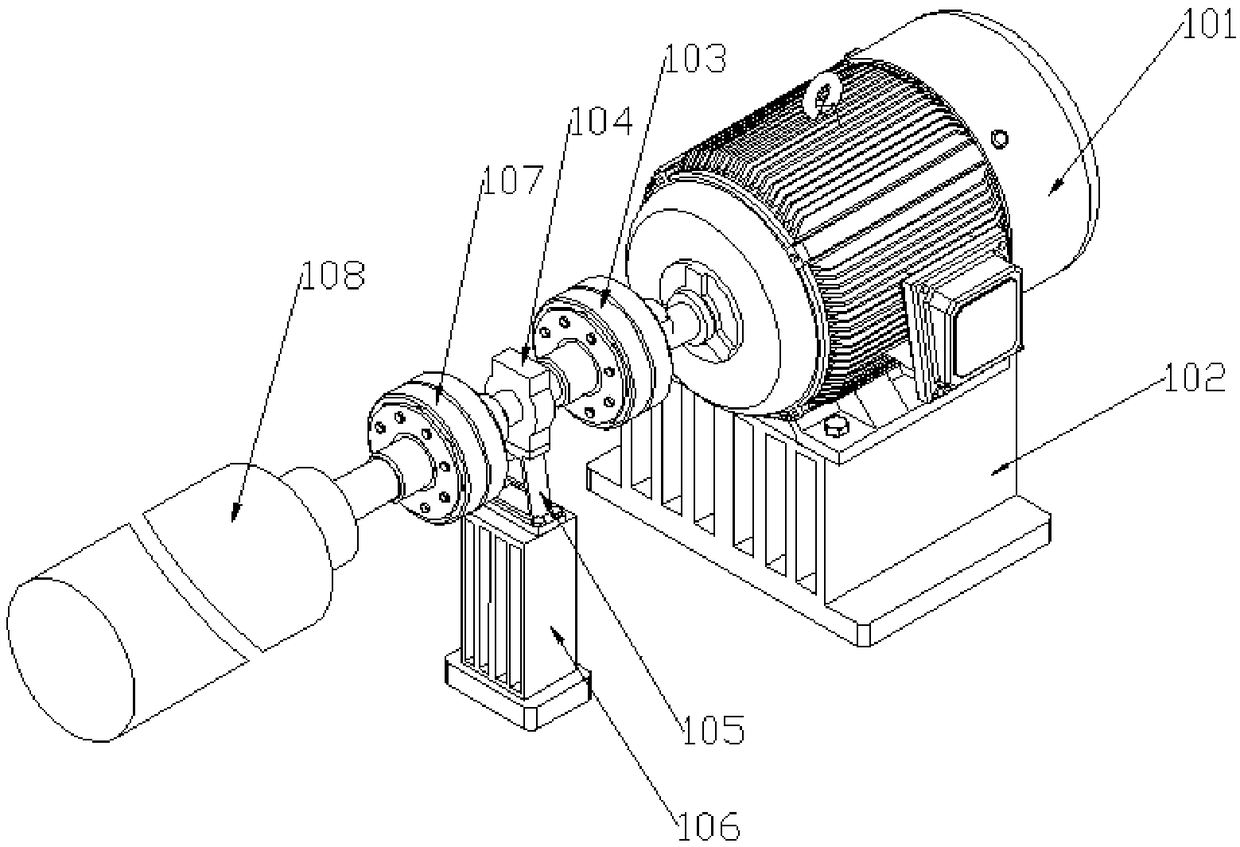

[0038] see figure 2 , the power output device 1 includes a frequency conversion speed regulation three-phase asynchronous motor 101, a first elastic diaphragm coupling 103, a rotational speed torque sensor 104, a second elastic diaphragm coupling 107, a central shaft 108, a variable frequency AC motor Base 102, rotational speed and torque sensor bracket 105, rotational speed and torque sensor bracket base 106, wherein, freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com