Telescopic type drive non-destructive detecting equipment

A non-destructive testing, telescopic technology, used in mechanical equipment, pipes/pipe joints/fittings, special pipes, etc., can solve the problems affecting the measurement accuracy of the measuring device, inability to pass, main body vibration, etc., to solve the problem of weight and quantity restrictions , The effect of improving the ability to overcome obstacles and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the embodiments and the accompanying drawings.

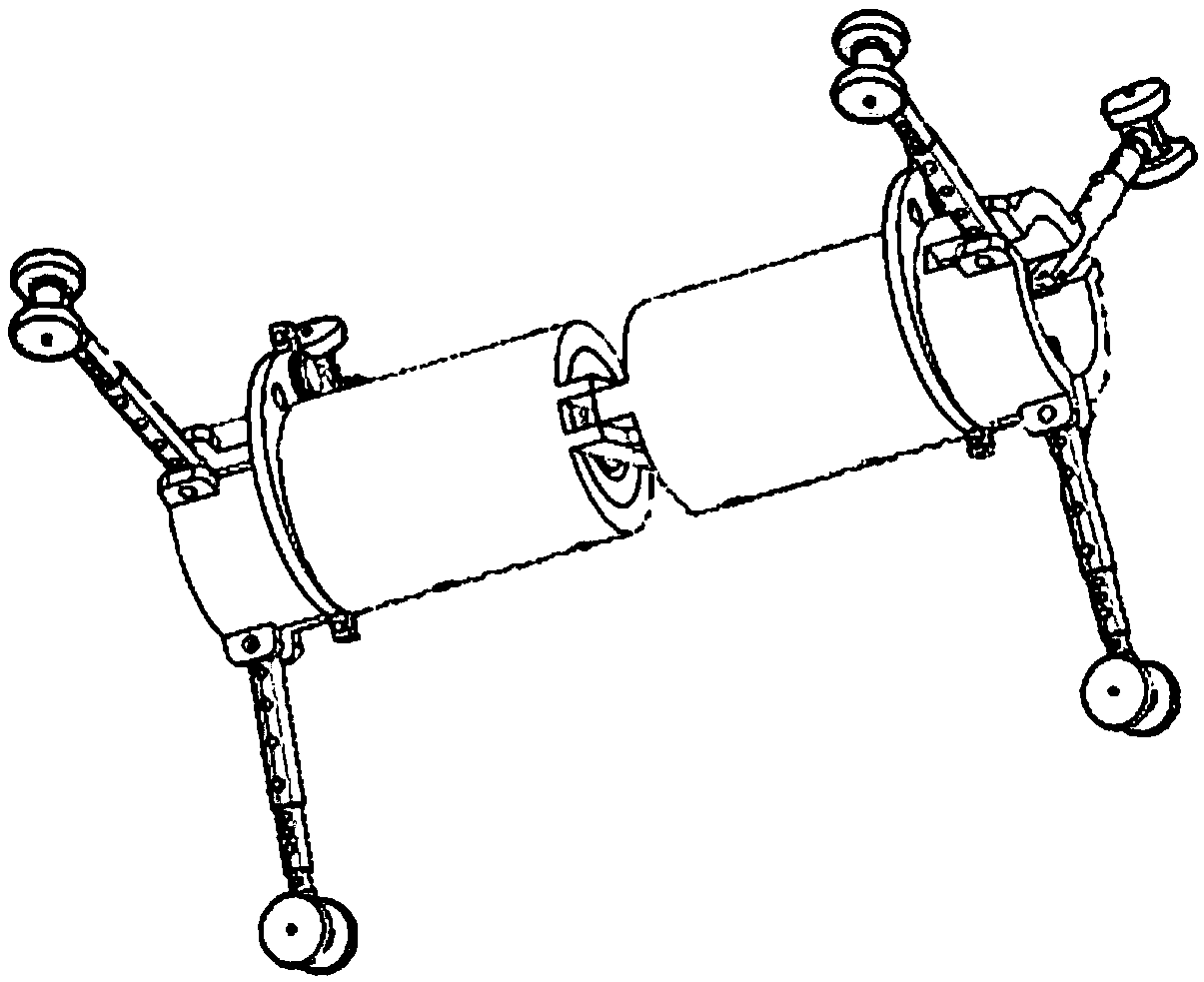

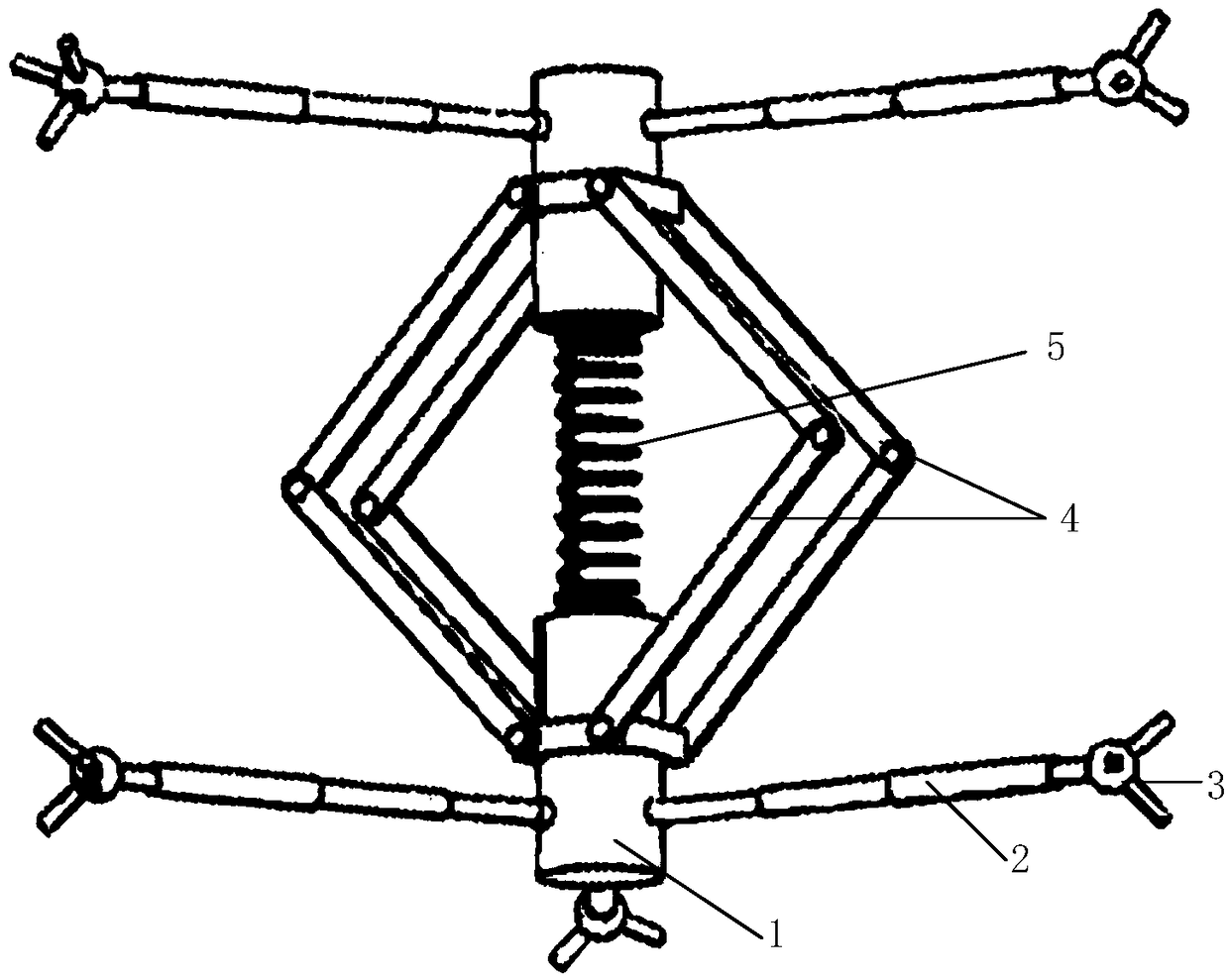

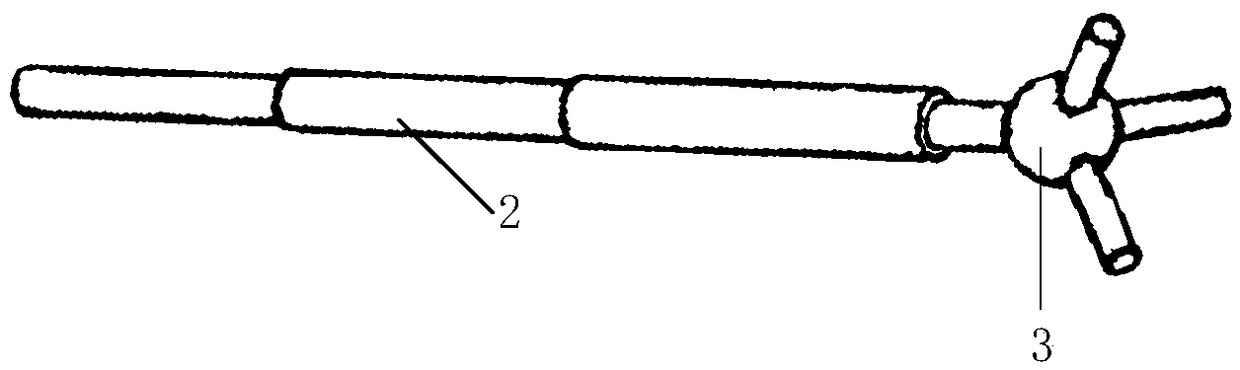

[0021] Such as figure 2 As shown, the structure of the telescopic drive non-destructive testing equipment includes: a main body 1, a support arm 2, a triangular claw 3, a connecting rod 4 and an elastic device 5;

[0022] The support arm is arranged on the upper and lower parts of the main body, and includes multiple pieces, each support arm includes multiple sections, and the sections can be stretched to form a telescopic support arm;

[0023] The triangular claws are arranged at the end of the support arm, so that the non-destructive testing equipment can be positioned stably during crawling;

[0024] The connecting rod is arranged between the support arms on the upper and lower parts of the main body, and one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com