Self-climbing hydraulic turnover formwork

A self-climbing, hydraulic technology, applied in the field of mold turning, can solve the problems of high operational safety risk, occupying head space, process interference, etc., and achieve the effect of simple connection method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. In explaining the embodiments of the present invention, if a detailed description of related well-known elements or functions interferes with the gist of the present invention, the detailed description will be omitted.

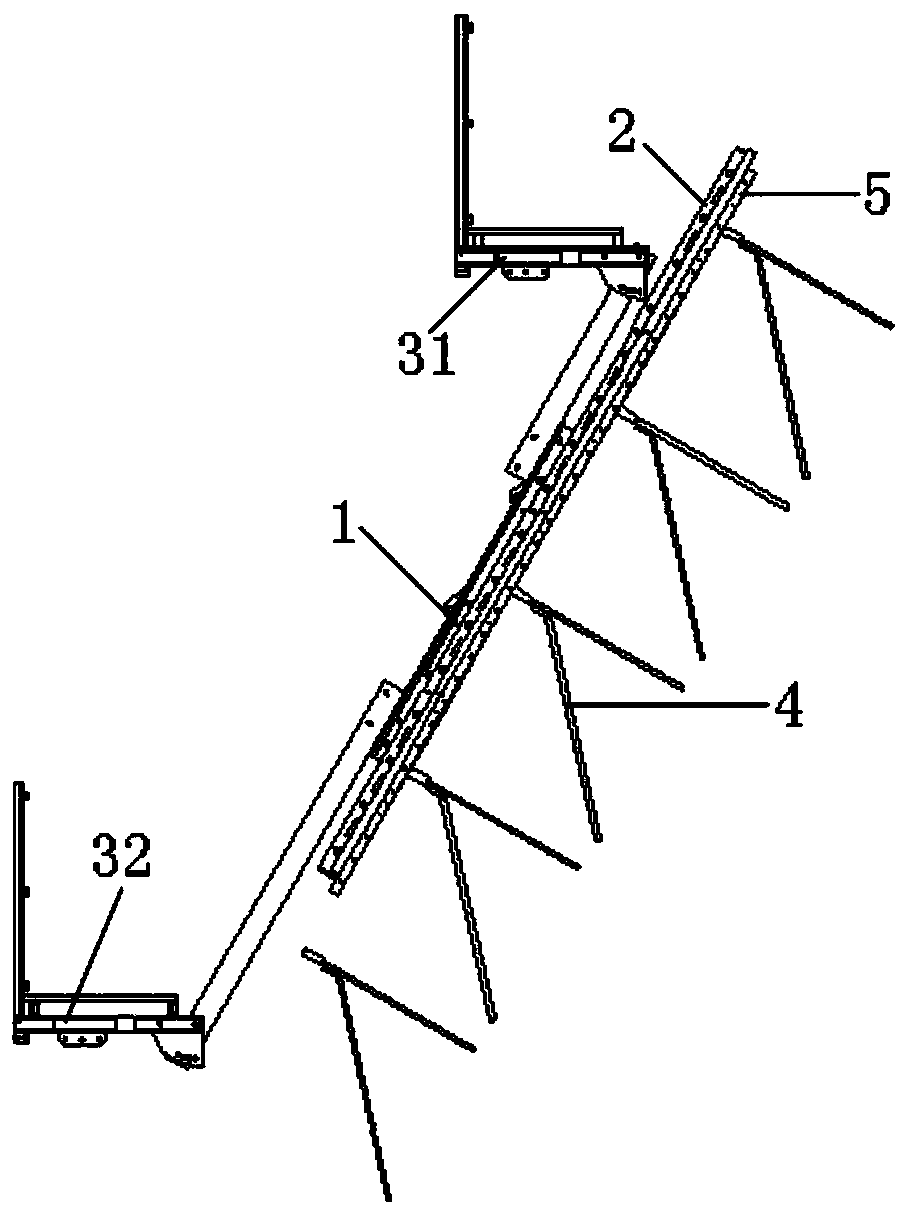

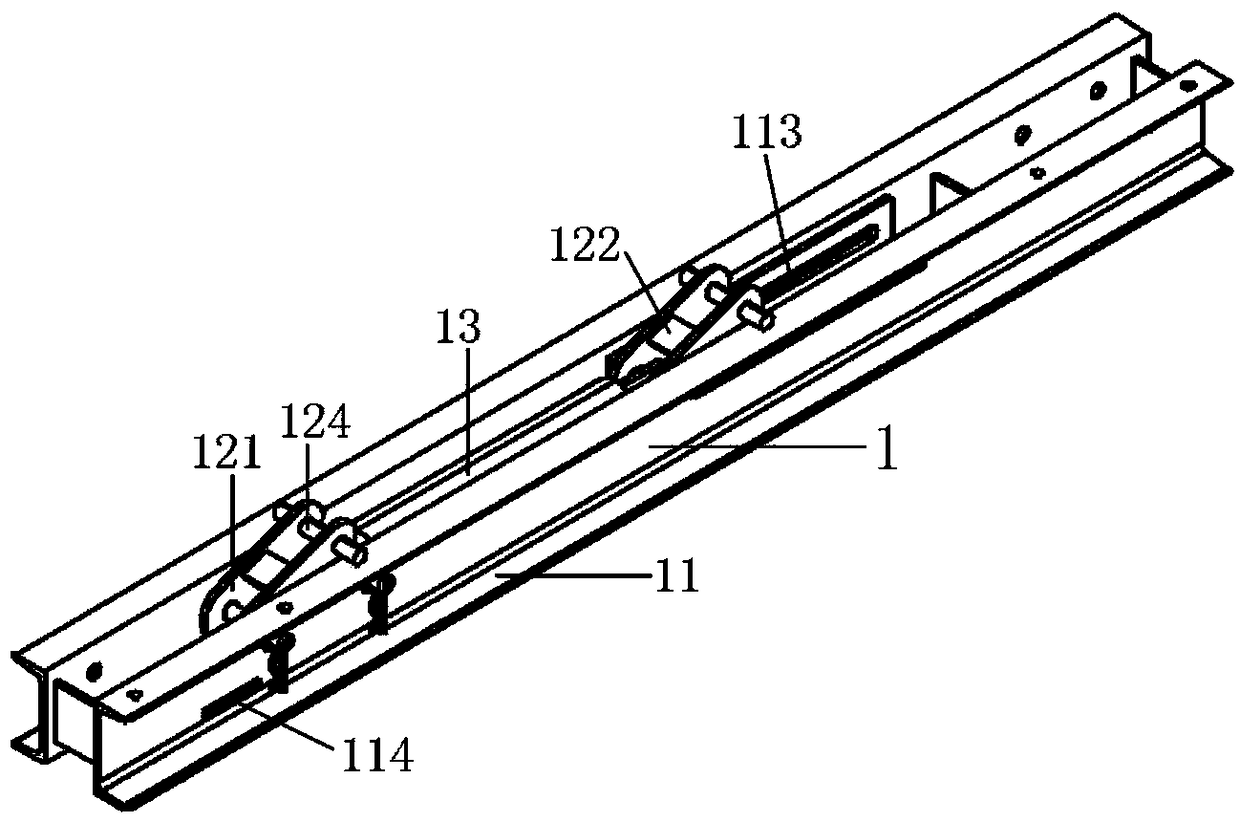

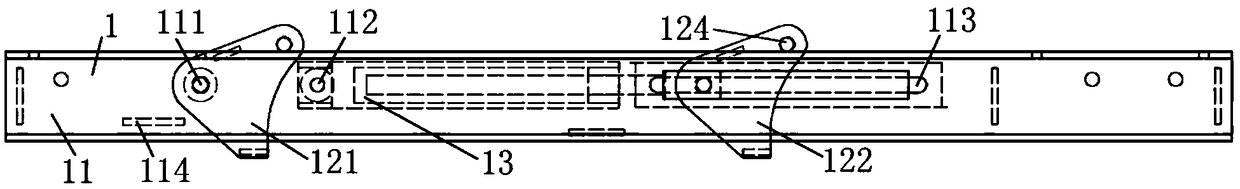

[0049] refer to Figure 1 to Figure 5b , a self-climbing hydraulic mold turning provided by the present invention includes a frame body climbing pole 11, a guide groove group 2, a climbing group 1, a template 5, a platform group, and embedded parts 4, and the guide groove group 2 passes through the embedded parts 4 is fixed on the formwork 5, and the climbing group 1 is used to realize that the frame body climbing pole 11 and the platform group climb along the guide groove group 2, and the template 5 and the platform group are carried out through the platform group. The reverse of the guide groove group 2, the alternate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com