Method of pile foundation construction in miscellaneous fill region and sludge region

A construction method and technology of miscellaneous soil filling, which are applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of difficult impact formation, silt trapped in manholes, waste holes or waste piles, etc., and reduce pollution. , The effect of avoiding drilling deflection and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

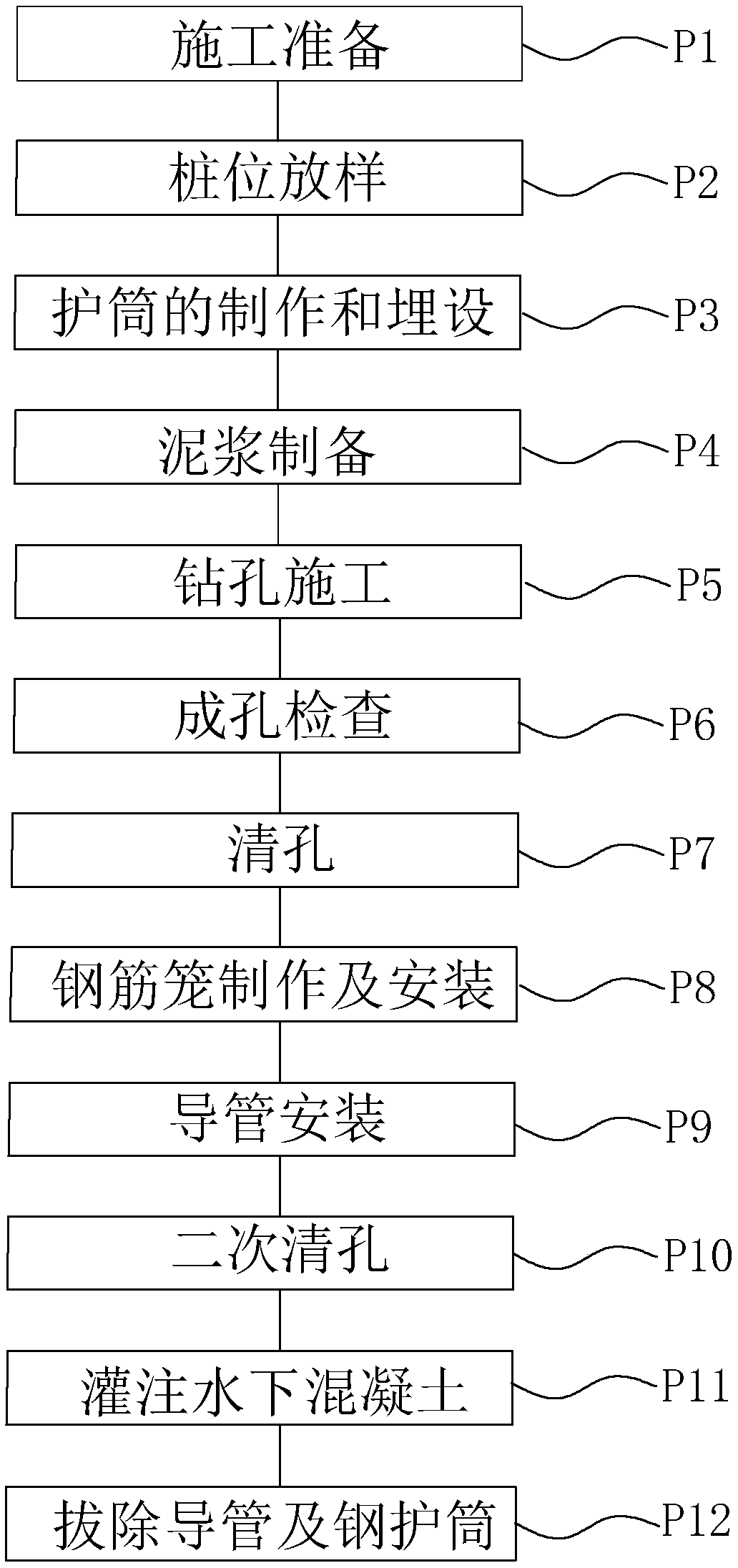

[0046] A pile foundation construction method in miscellaneous fill and silt zone, such as figure 1 shown, including the following steps:

[0047] P1: Construction preparation: Before pile foundation construction, ascertain the geological conditions of the site and remove debris from the site.

[0048] Replace the soft soil with a depth of 0.6-1.0m in the upper layer, mix it with 15% lime on the spot, backfill after even mixing, level and tamp it with an excavator or road roller, sprinkle water for 7 days, and lay the road base to form a construction access road , The construction access road and the construction site need to be rolled and trimmed into a smooth slope, so that the drilling rig and construction vehicles can enter and exit the construction access road smoothly. After the construction access road is completed, the layout of the drilling site is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com