Method for fixing connectors to vehicle body connecting frame and fixing draught fan to condenser

A fixing method and a technology of connecting parts, which are applied to vehicle components, heating/cooling equipment, air handling equipment, etc., can solve the problems of increasing production costs and complicated processing technology, and achieve simplified processing procedures, low operation difficulty coefficient, and reduced welding The effect of operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

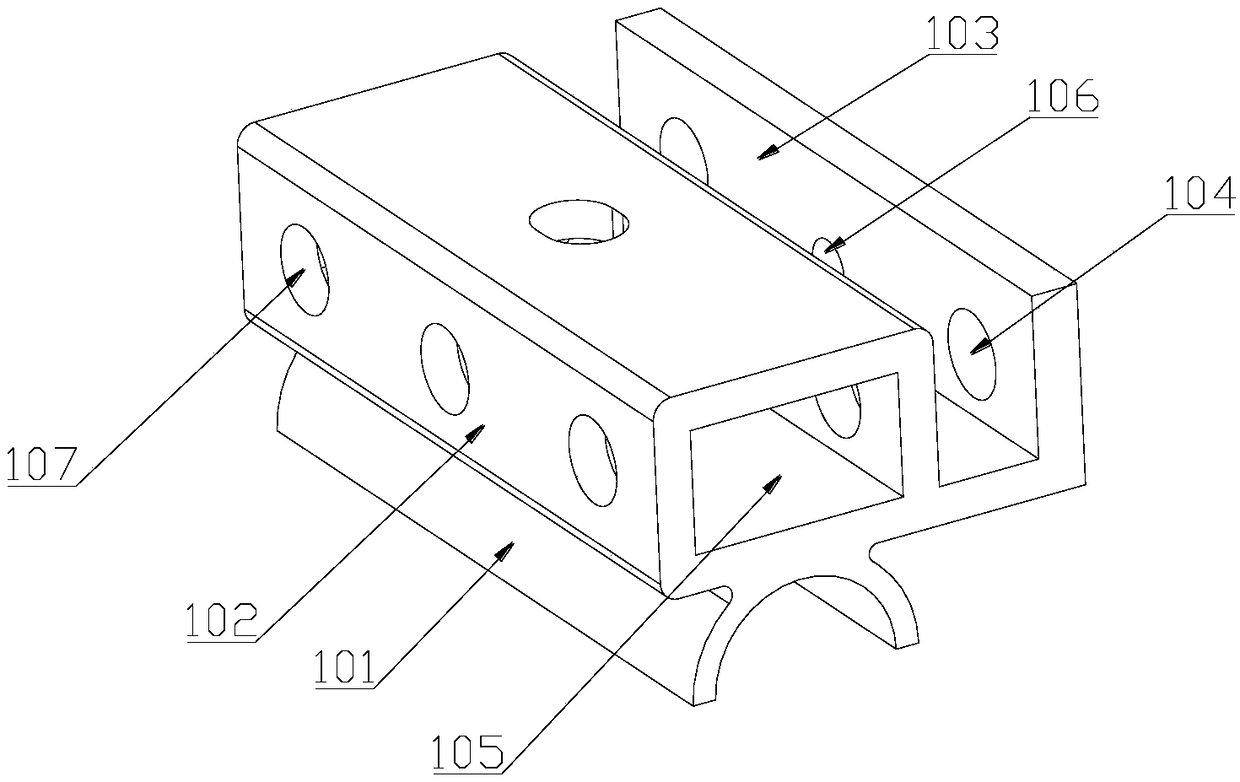

[0026] Example 1, such as figure 1 As shown, a connecting piece includes a condenser connecting plate 101, the condenser connecting plate 101 is an arc-shaped plate, the condenser connecting plate 101 is provided with a frame connecting block 102, and the vehicle frame connecting block 102 A fan connecting plate 103 is arranged on one side of the fan, and the fan connecting plate 103 is fixedly connected with the frame connecting block 102 .

[0027] The condenser connecting plate 101 is a semicircular plate, the frame connecting block 102 is provided with a frame connecting hole 107, the fan connecting plate 103 is provided with a fan connecting hole 106, and the vehicle frame connecting hole 107 The aperture of the fan connecting hole 106 is equal to that of the fan connecting hole 106. The fan connecting plate 103 is provided with a relief hole 104 corresponding to the frame connecting hole 107, and the center line of the relief hole 104 is aligned with the vehicle frame T...

Embodiment 2

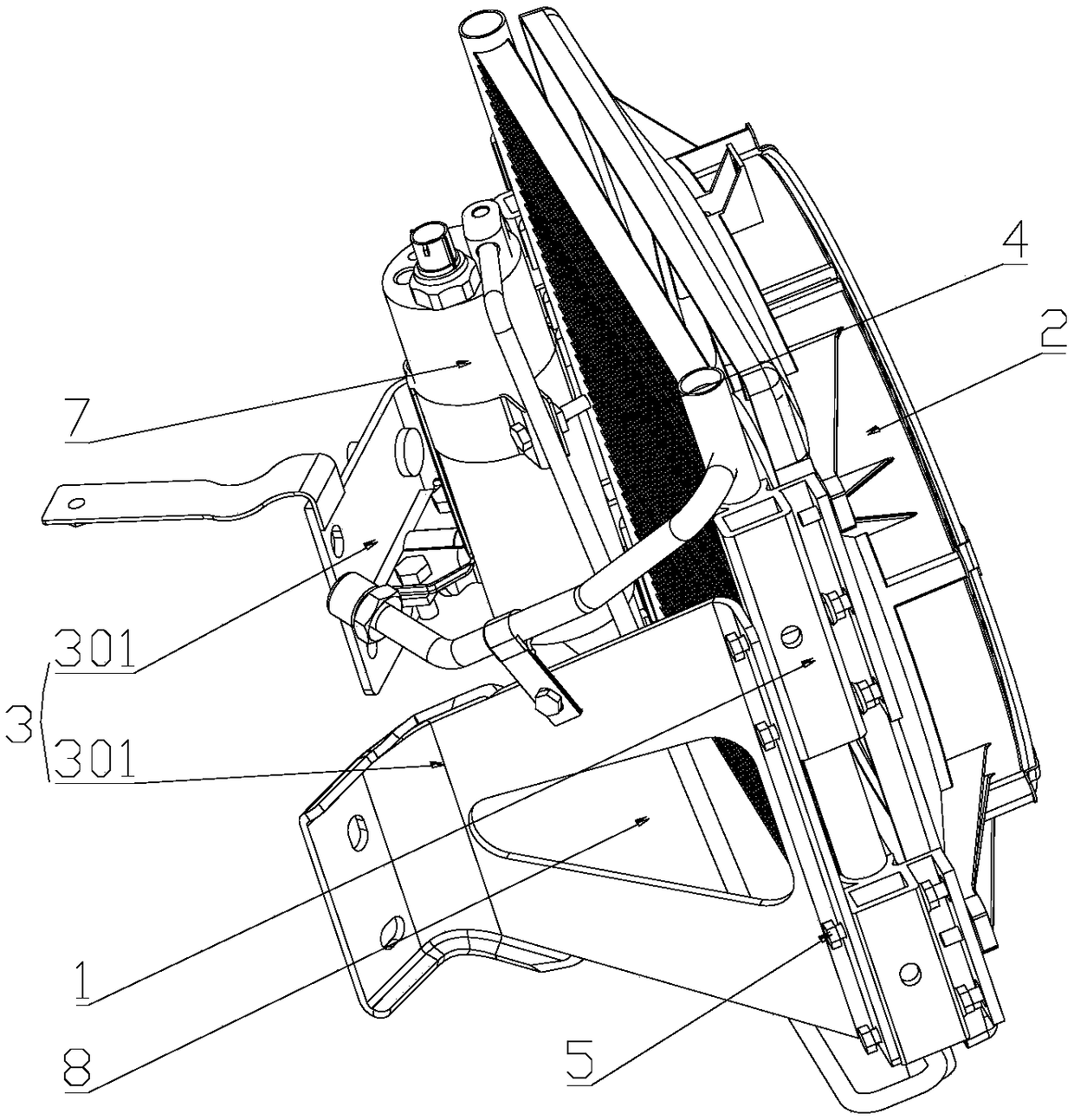

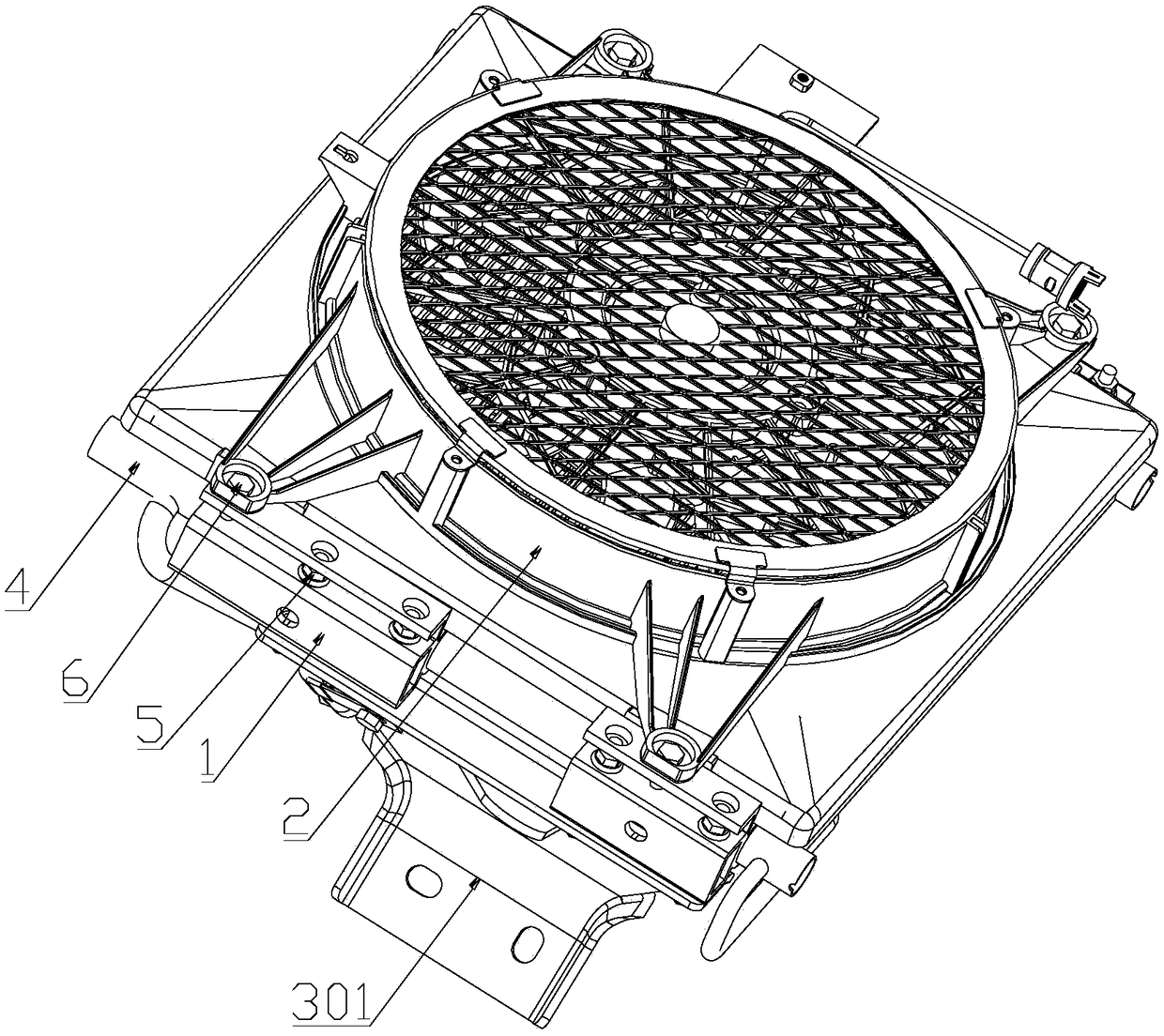

[0030] Example 2, such as figure 2 and 3 As shown, a method for fixing the body connecting frame, the fan and the condenser is carried out according to the following steps:

[0031] (1) Profile processing: take the connector described in Example 1 (for convenience of description, the connector is marked as serial number "1") as a model, and cast a strip-shaped profile consistent with its structure for subsequent use;

[0032] (2) Profile cutting: cutting the elongated profile to obtain N connectors 1, where N is a natural number greater than or equal to 2;

[0033] (3) Welding: two connectors 1 are respectively installed on the left and right sides of the condenser body 4, and the two connectors 1 are respectively close to the upper and lower parts of the condenser body 4, and the condenser connecting plate 101 of the connector 1 It is a semicircular plate, which is welded on the pipeline of the condenser body 4;

[0034] (4) Fixing the body connecting frame: the body conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com