Intelligent-manufacturing-field-oriented mobile machine tool fault diagnosis robot

A fault diagnosis and intelligent manufacturing technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, measuring/indicating equipment, etc., can solve the problems of difficult machine fault diagnosis, high diagnostic cost, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

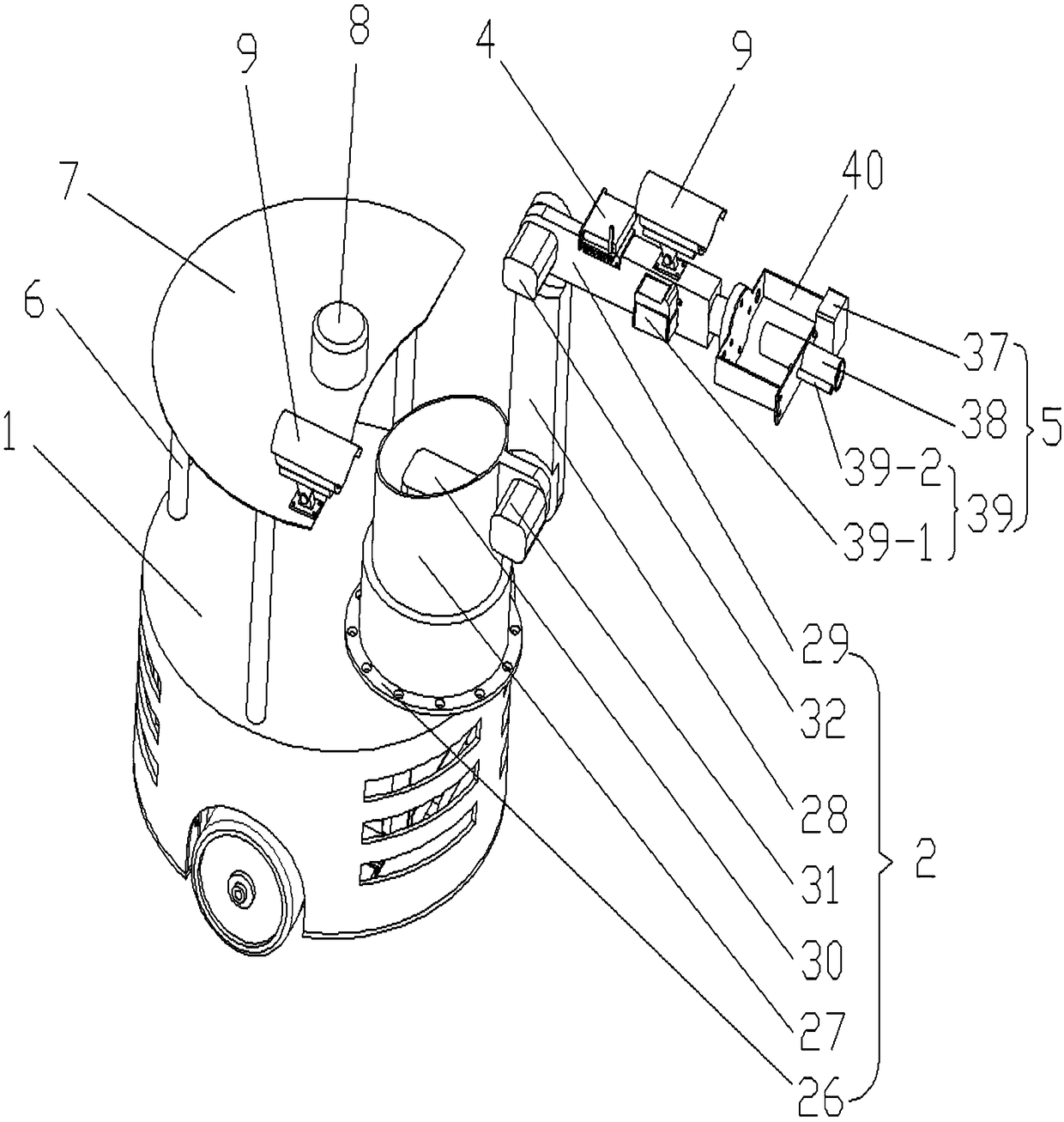

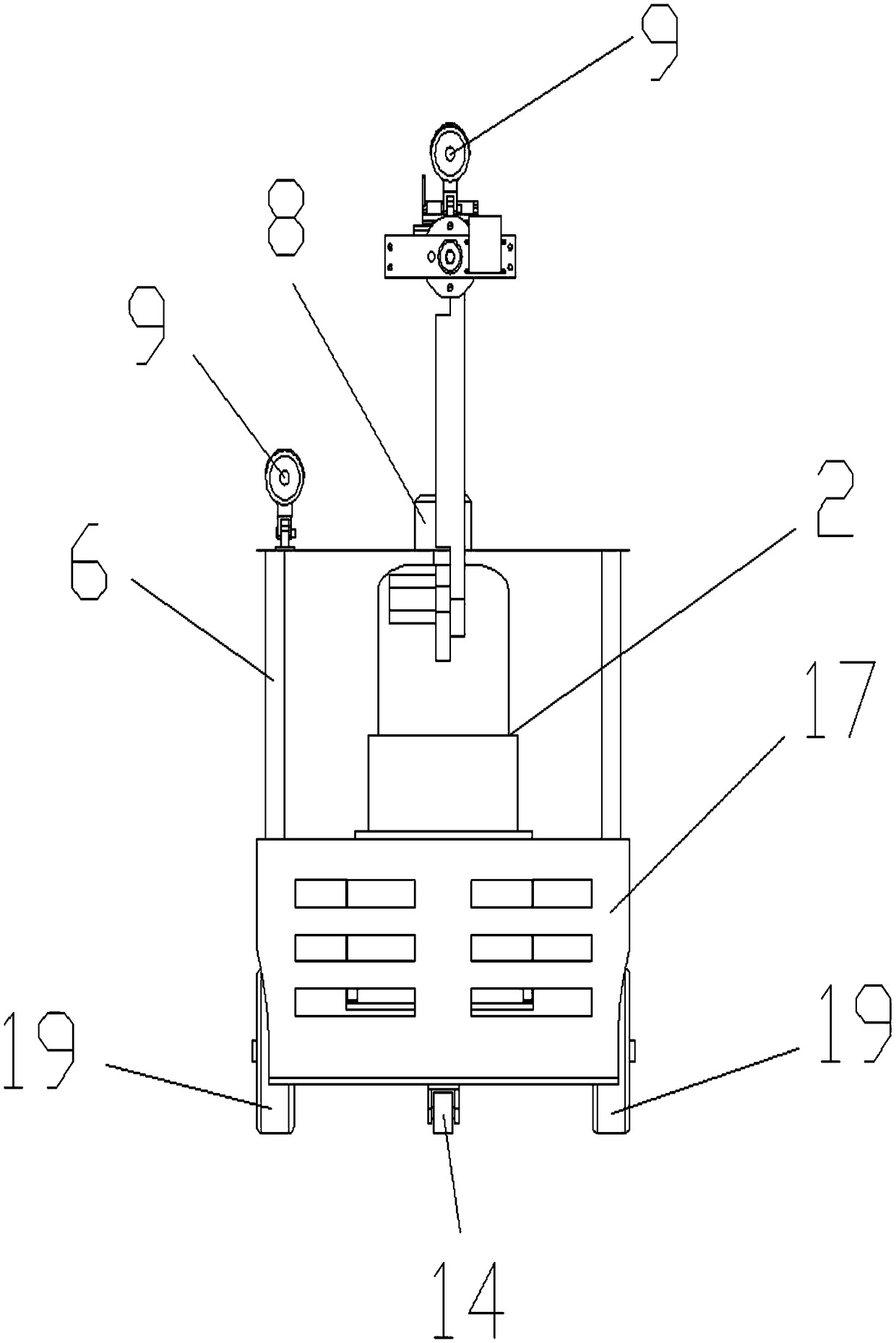

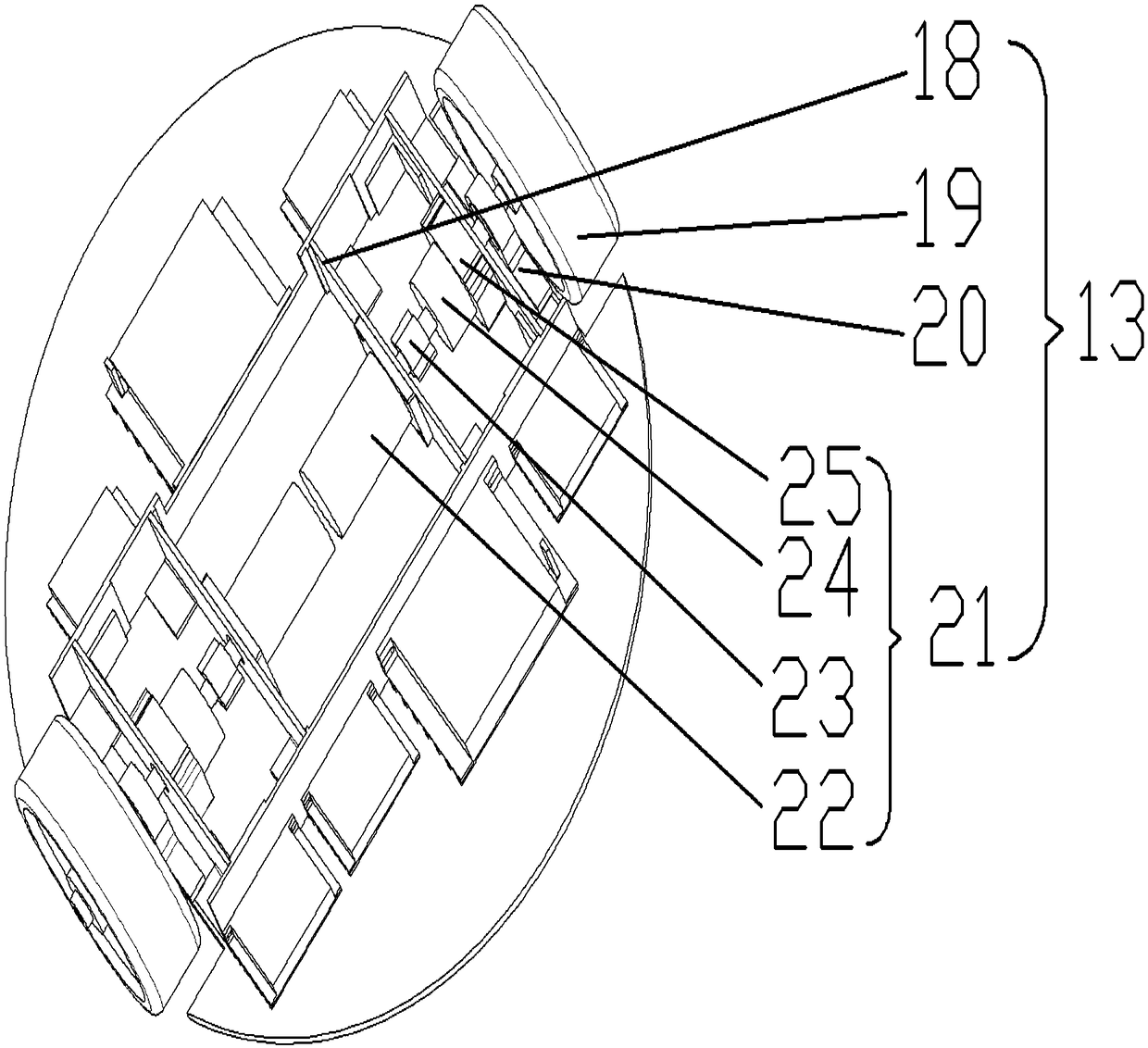

[0022] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0023] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

[0024] 1 is the mobile chassis, 2 is the manipulator module, 3 is the pose adjustment module, 4 is the signal collector, 5 is the sensor module, 6 is the support column, 7 is the support plate, 8 is the laser radar, 9 is the camera, and 10 is the battery frame, 11 is the power supply battery, 12 is the bottom plate, 13 is the driving wheel mechanism, 14 is the bottom wheel, 15 is the chassis controller, 16 is the motor driver, 17 is the shell, 18 is the fixed frame, 19 is the driving wheel, 20 is the bearing Seat, 21 is a wheel drive assembly, 22 is a motor, 23 is a first coupling, 24 is a speed reducer, 25 is a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com