Intelligent integrated equipment and bending method applying intelligent integrated equipment

An integrated equipment and intelligent technology, applied in the field of bending, can solve problems such as unqualified bending, low bending efficiency, misoperation, etc., and achieve the effect of reducing size deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

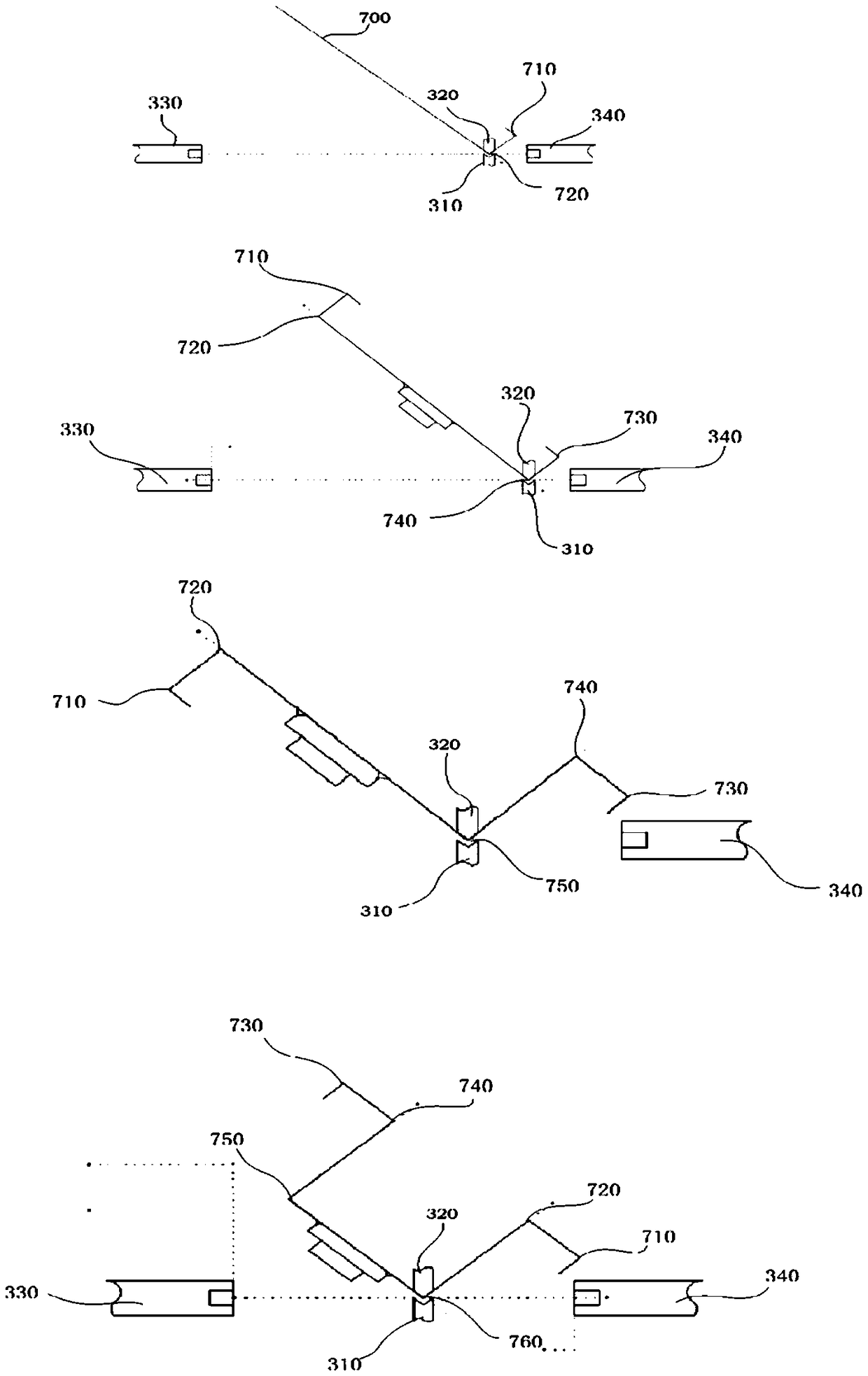

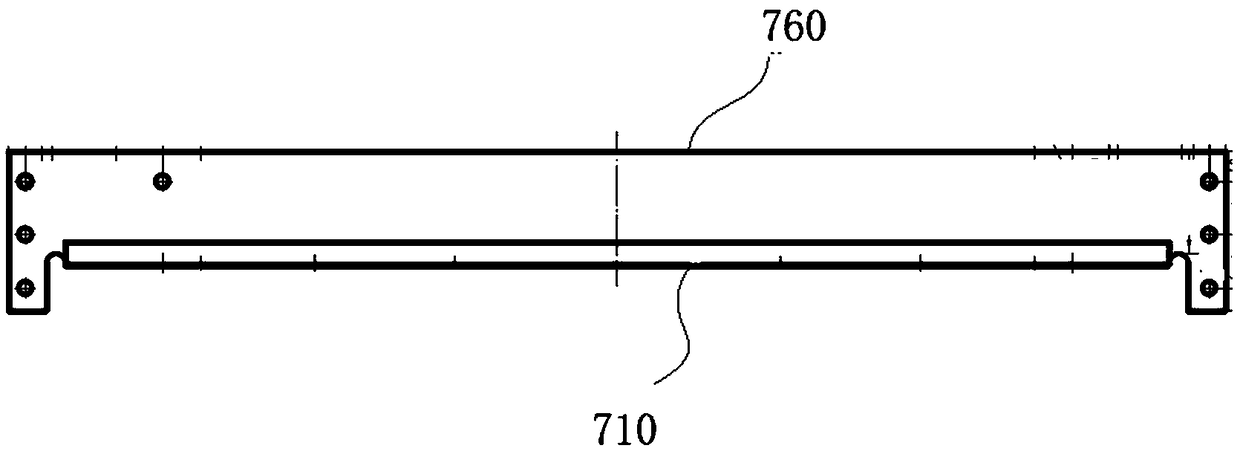

[0038] The bending method using intelligent integrated equipment is characterized in that it includes the steps of:

[0039] Recognize the thickness and shape of the workpiece 700; specifically, identify the category of the workpiece 700 through the visual unit 100, and then detect the thickness of the workpiece 700 after the upper mold moves down to give the workpiece an initial pressure, and further confirm which workpiece 700 is different types of workpieces 700, in this embodiment, the intelligent integrated device can distinguish workpieces 700 with different thicknesses of 1.5, 2.0, 2.5, 3.0, 4.0, 5.0, and 6.0, and identify them from the six workpieces 700 with different thicknesses There are more than 700 workpieces of more than 200 different shapes and specifications.

[0040] Call the lower mold assembly and bending parameters corresponding to the workpiece 700; the controller 200 is used to issue instructions; when identifying the specific category of the workpiece 7...

Embodiment 2

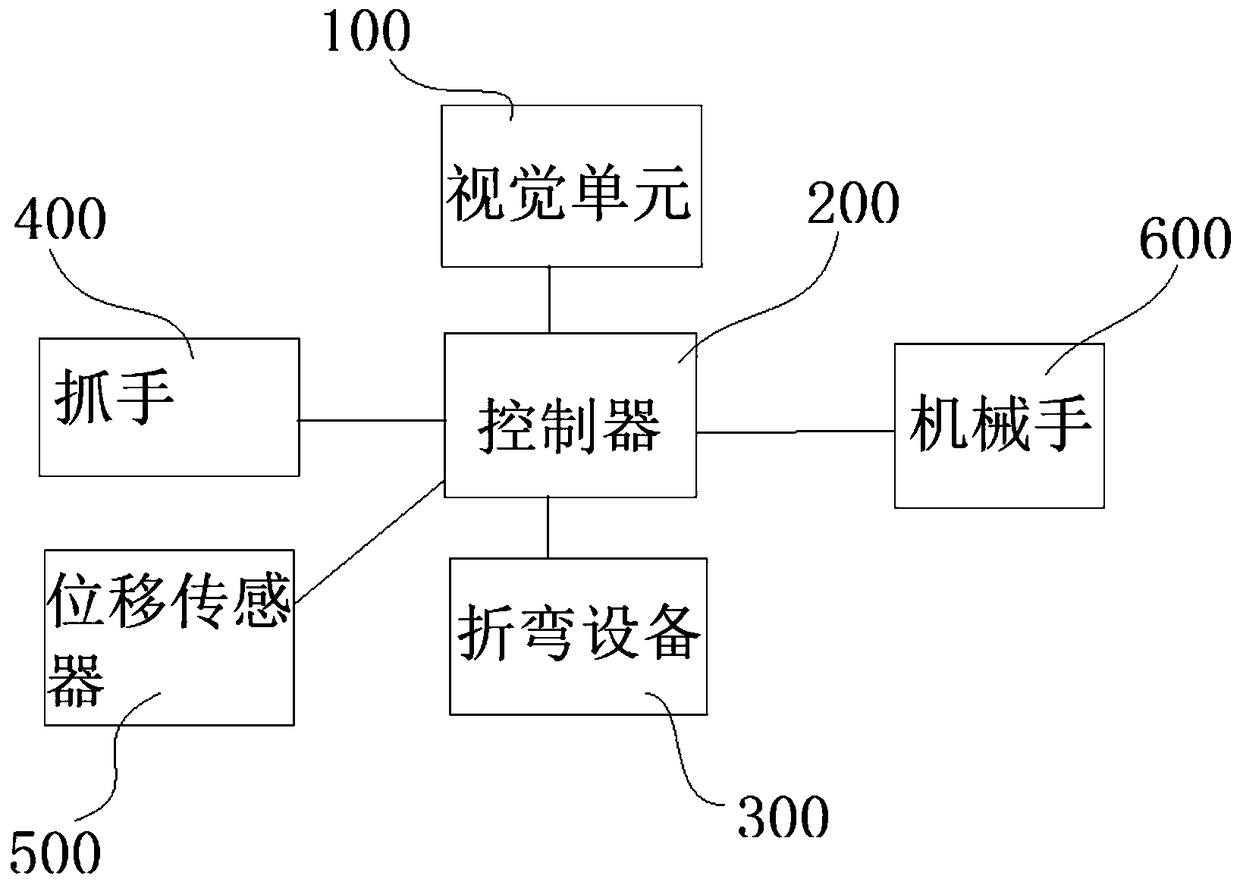

[0055] The intelligent integrated device is characterized in that; comprising:

[0056] The vision unit 100 is used to identify the category of the workpiece 700; the vision unit 100 has a camera, and the camera is used to take a photo of the workpiece 700; collect feature points and shapes in the workpiece 700, and then compare them with the feature points of pre-stored various workpieces 700 Compared with the shape, the specific category of the workpiece 700 is then identified.

[0057] The controller 200 is used to control and call various lower die components and various bending parameters; to control the gripper 400, the manipulator 600, and the upper die 320 by issuing instructions, and to set the processing program to control the entire bending process. Various types of bending are pre-stored in the intelligent integrated device, and are called by the controller 200 when the specific type of the workpiece 700 is identified.

[0058] The gripper 400 is used to grab the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com