Cleaning device for rubber plugs for medical drugs

A technology of cleaning device and rubber stopper, which is applied in the direction of cleaning method using tools, cleaning method using liquid, cleaning method and utensils, etc., to achieve the effect of good cleaning, thorough cleaning and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

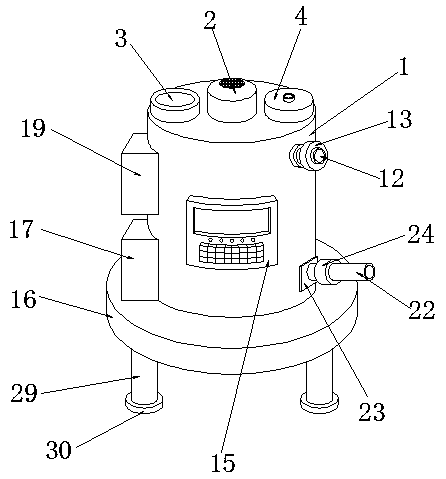

[0025] Embodiment one, such as Figure 1-2 As shown, a cleaning device for rubber stoppers for pharmaceuticals according to an embodiment of the present invention includes a cleaning tank 1, a motor 2 is installed on the top of the cleaning tank 1, and the top of the cleaning tank 1 is located on the One side of the motor 2 is provided with a feeding port 3, the top of the cleaning tank 1 and the side of the motor 2 away from the feeding port 3 is equipped with a lotion box 4, and the bottom of the lotion box 4 is A liquid outlet pipe 5 is connected, and the bottom end of the liquid outlet pipe 5 runs through the top of the cleaning tank 1 and extends to the inside of the cleaning tank 1, and the liquid outlet pipe 5 is equipped with a solenoid valve- 6. The bottom of the motor 2 is connected with a rotating shaft 7, and the bottom end of the rotating shaft 7 penetrates and extends to the inside of the cleaning tank 1, and the bottom end of the rotating shaft 7 is provided wit...

Embodiment 2

[0026] Embodiment two, such as figure 1 As shown, the control panel 15 is sequentially provided with a display screen, indicator lights and operation keys from top to bottom; it is convenient to control each component. .

Embodiment 3

[0027] Embodiment three, such as figure 1 Or as shown in 2, a discharge pipe 22 is connected to the outside of the discharge port 14, and a fixing member 23 is installed at the connection between the discharge pipe 22 and the discharge port 14. Electromagnetic valve 24 is installed; it is convenient to control the discharge, and can also ensure the stability of the discharge pipe 22 to achieve a stable discharge effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com