Processing method of black locust flower tea replacement

A processing method and acacia flower technology are applied in the field of tea processing to achieve the effects of high edible value and medicinal value, improving mental state, and simple and easy processing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

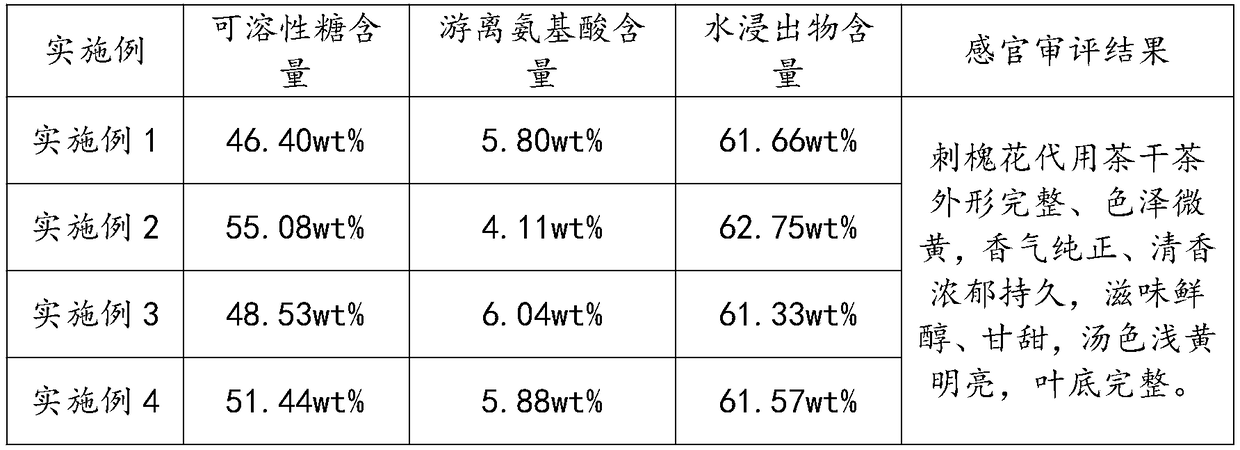

Examples

Embodiment 1

[0023] A. Pick the locust inflorescences that are about to bloom, remove the stems and keep the flowers, and remove the mildewed, smelly, dry and withered flowers for later use;

[0024] B, the processed black locust flower in step A is naturally tiled on the bamboo raft sieve, and its thickness is 1.5cm, spread cool until the water content of black locust flower is 65wt%, turn up and down once every 4h during the cool spread, spread The temperature of the cool environment is controlled at 15°C for standby;

[0025] C, spread the black locust flower after cooling in step B naturally on the wire mesh screen, its thickness is 0.8cm, then be placed in 110 ℃ of ovens and bake until the water content of black locust flower is 40wt%, then take out the black locust flower and carry out Let it cool for 30 minutes, set aside;

[0026] D. Rearrange the black locust flowers after cooling in step C and lay them flat on the wire mesh sieve with a thickness of 1.0cm, and place them in a 70...

Embodiment 2

[0029] A. Pick the locust inflorescences that are about to bloom, remove the stems and keep the flowers, and remove the mildewed, smelly, dry and withered flowers for later use;

[0030] B, the black locust flower processed in the step A is naturally tiled on the bamboo raft sieve, and its thickness is 1.8cm, and it is cooled until the water content of the black locust flower is 68wt%, and it is turned up and down once every 4h during the cooling period. The temperature of the cool environment is controlled at 20°C for standby;

[0031] C. Lay the black locust flower after cooling in step B naturally on the iron mesh screen, its thickness is 1cm, then place it in a 115°C oven and bake until the water content of the black locust flower is 42wt%, then take out the black locust flower and spread it Cool for 40 minutes, set aside;

[0032] D, rearrange the black locust flower after cooling in step C and spread it on the wire mesh screen, its thickness is 1.3cm, and place it in a ...

Embodiment 3

[0035] A. Pick the locust inflorescences that are about to bloom, remove the stems and keep the flowers, and remove the mildewed, smelly, dry and withered flowers for later use;

[0036] B, the black locust flower processed in the step A is naturally tiled on the bamboo raft sieve, and its thickness is 2.0cm, and it is cooled until the water content of the black locust flower is 70wt%, and it is turned up and down every 4h during the cooling period, and spread The temperature of the cool environment is controlled at 25°C for standby;

[0037] C, spread the black locust flower after cooling in the step B naturally on the wire mesh screen, its thickness is 1.2cm, then be placed in 120 ℃ of ovens and bake until the water content of the black locust flower is 45wt%, then take out the black locust flower and carry out Let it cool for 60 minutes, set aside;

[0038] D. Rearrange the black locust flowers after cooling in step C and lay them flat on the wire mesh sieve with a thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com