Rotary intelligent end stripper

A smart-end, rotary technology, applied in instruments, circuit/collector parts, measuring devices, etc., can solve the problems of deformation of the insulating sheath, affecting the use of tools, difficulty in peeling, etc., to avoid cutting damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0031] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

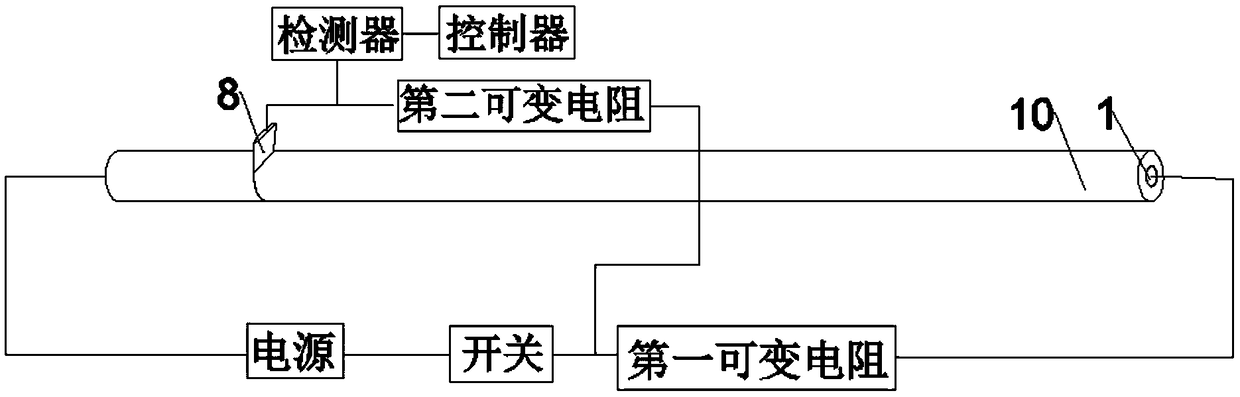

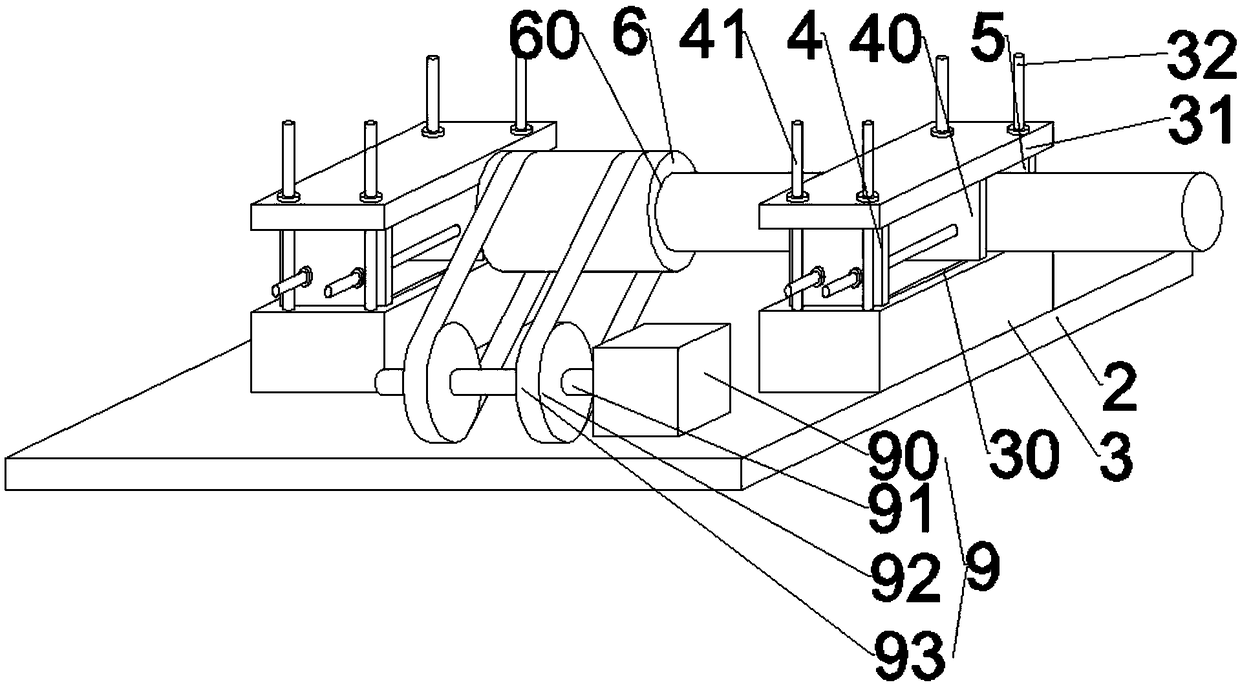

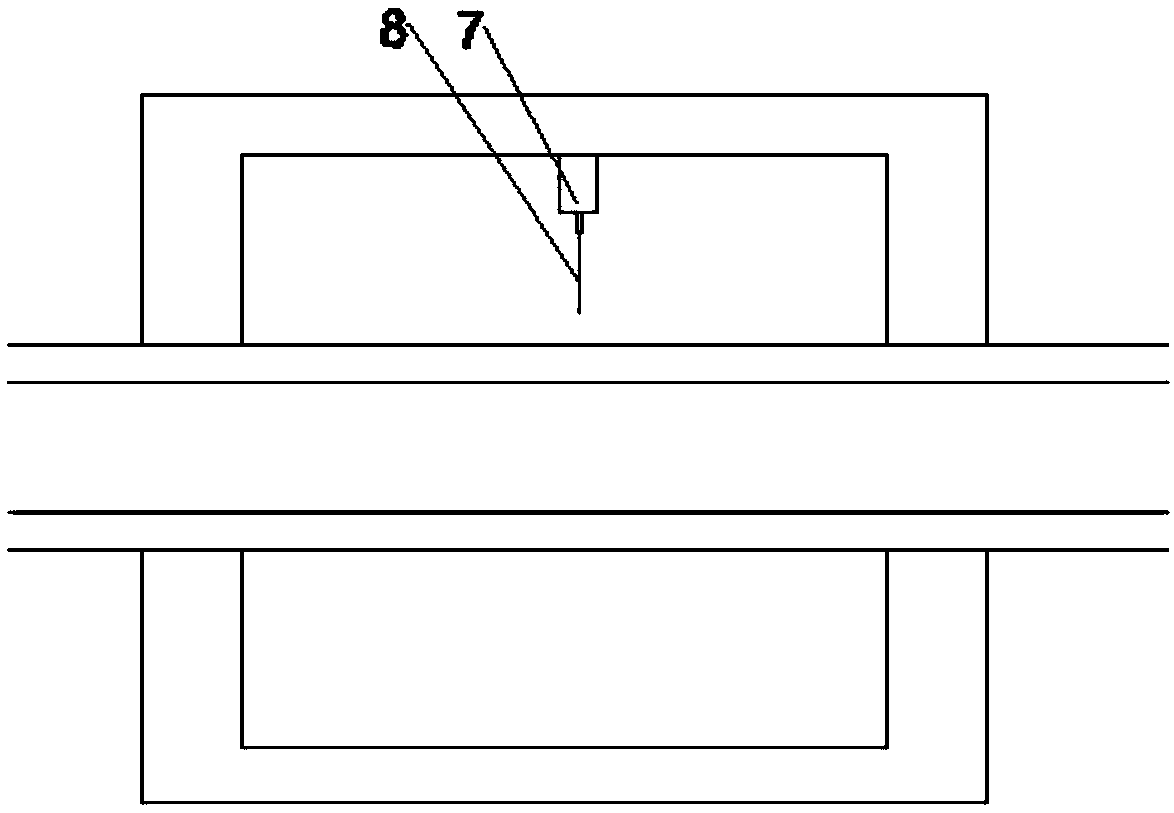

[0032] Such as Figure 1-4 As shown, the present invention provides a rotary intelligent end stripper. The wire to be stripped includes a wire body 1 and an insulating sheath 10 coated outside the wire body 1, including:

[0033] Base 2;

[0034]A pair of fixing mechanisms, each fixing mechanism includes a cuboid horizontal seat 3 fixed on the base 2, and the top of the horizontal seat 3 is vertically fixed respectively near its opposite two edges (the opposite two edges along the length direction). The first telescopic plate 4, the top of the two first telescopic plates 4 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com