HDPE double-wall corrugated winding pipe

A coiled pipe and corrugated technology, applied in the field of HDPE double-wall corrugated coiled pipe, can solve the problems of cracking at the lap joint of the pipe body, and achieve the effect of preventing local rupture, improving the energy absorption capacity, and solving the cracking of the lap joint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

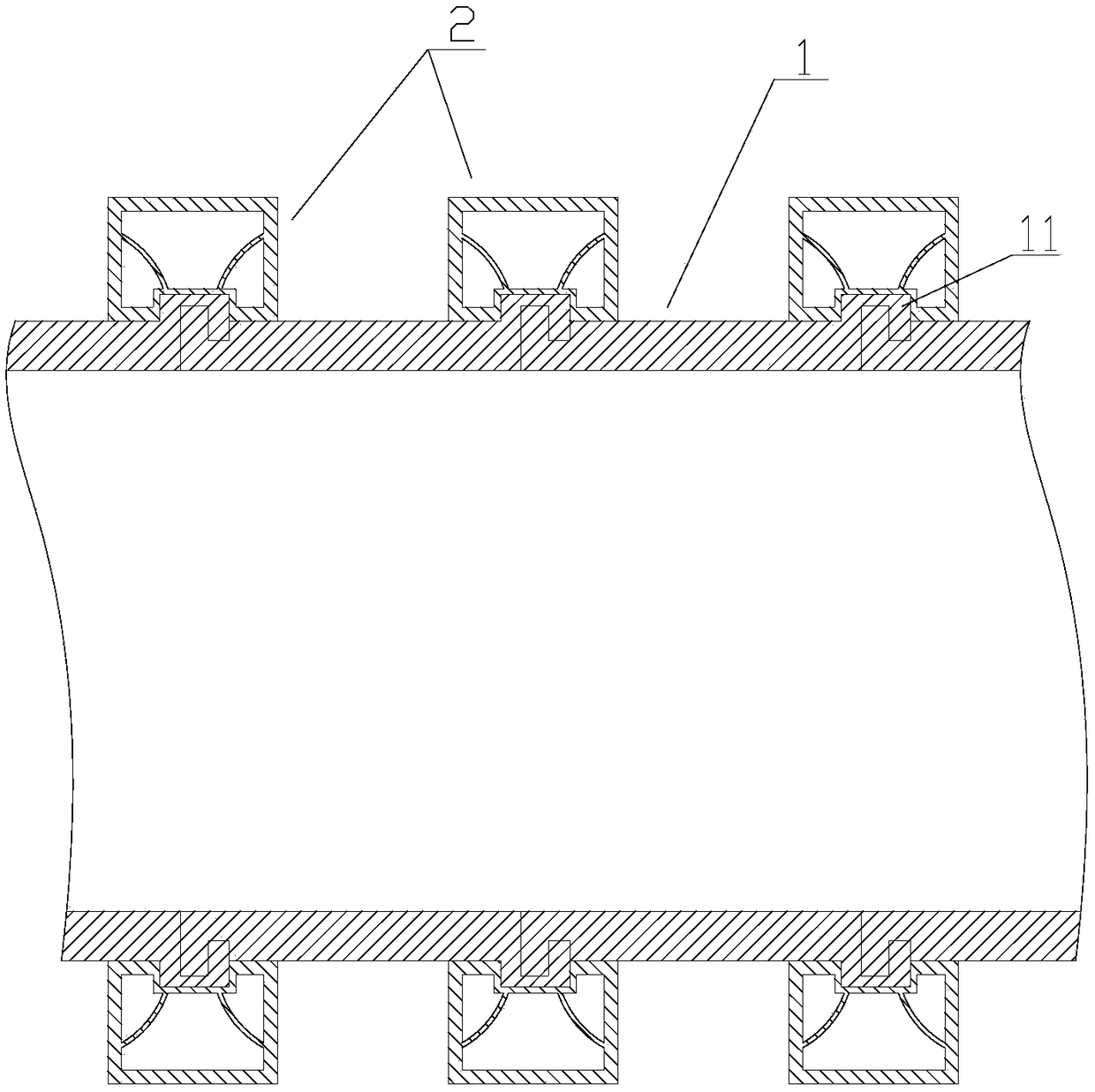

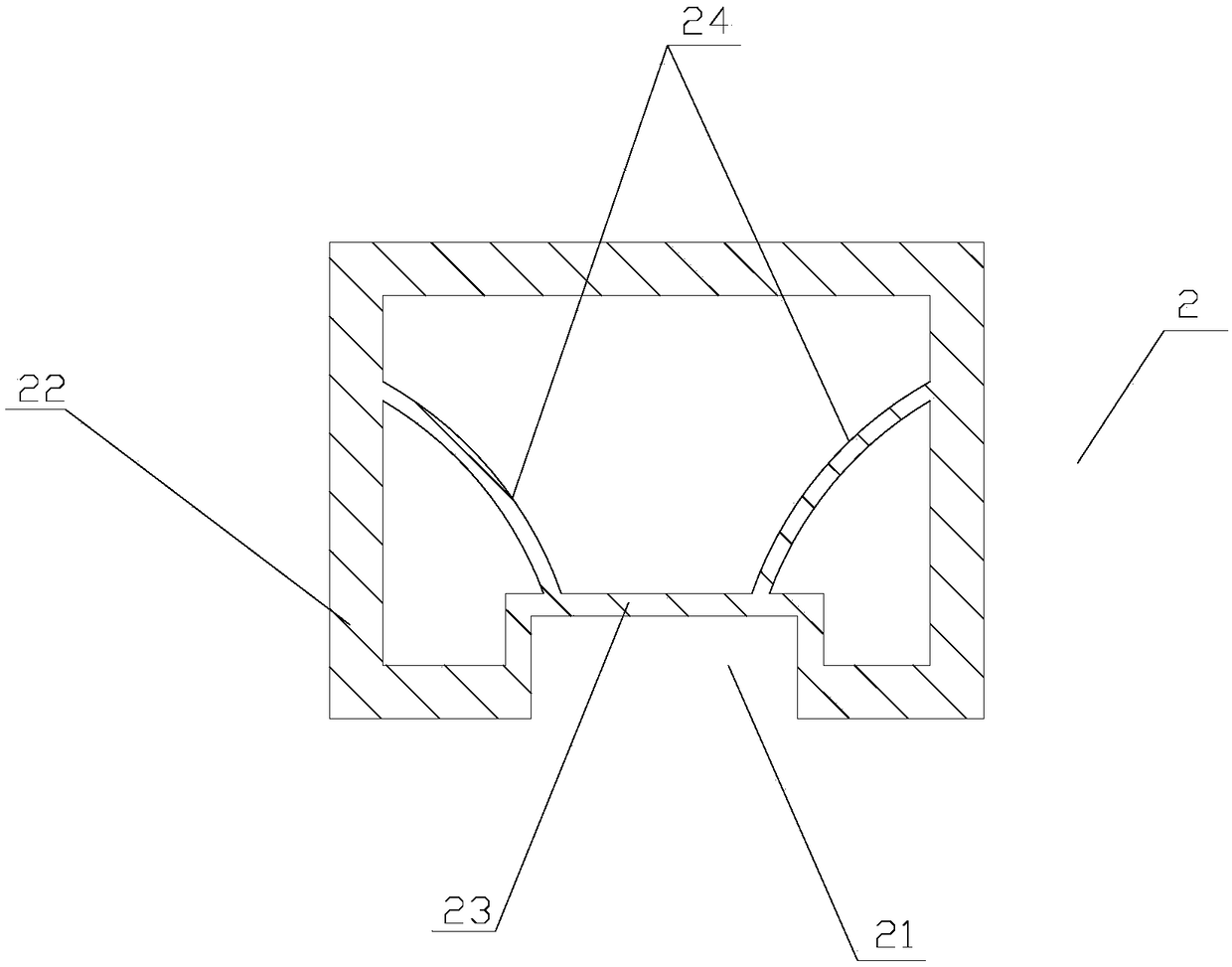

[0020] Such as Figure 1~2 As shown, the present invention provides a HDPE double-wall corrugated winding pipe, which has a pipe body 1 with a smooth inner wall. The pipe body 1 is made of HDPE material. Since the drain pipe needs to have a large radius, the conventional method cannot be completed. The pipe body 1 is completed by winding molding. Firstly, a strip-shaped HDPE material strip 12 is obtained by extrusion molding. The strip 12 is wound on a core rod in a spiral manner by a winding feeder. The two sides of the strip 12 in the width direction The ends have an overlapping structure so that after winding the two ends overlap each other and are thermally fused together. With such a manufacturing method, large-diameter pipes that cannot be obtained in conventional methods can be obtained, and the diameter of the pipe can reach more than 2m. The ring stiffness of the pipe is also increased by the hollow strip 2 arranged outside the pipe body 1 , the hollow strip 2 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com