CO2 preparation high-pressure fracturing coal mine gas permeability enhancement and replacement method in coal seam

A gas and fracturing technology, applied in the field of gas permeability enhancement and replacement, can solve problems such as low efficiency of coal seam hydraulic fracturing, and achieve the effects of reducing the harm of coal dust, saving manpower and material resources, and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

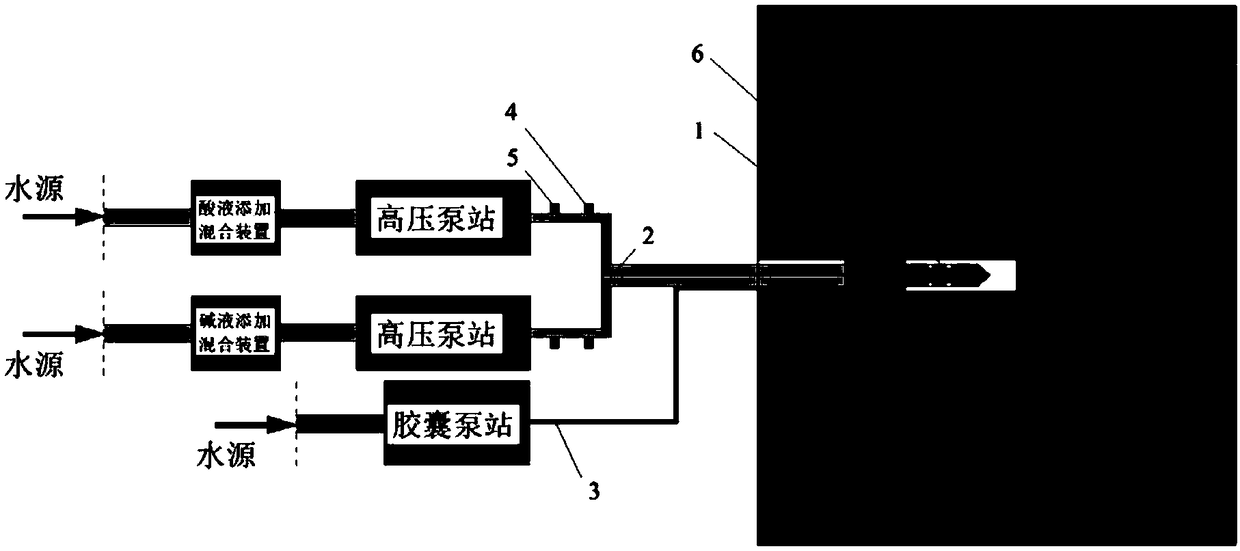

[0048] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

[0049] In the technical field of anti-permeability and gas replacement of gas-containing coal seams in the coal mining industry, two methods are generally used in the prior art. The first type of hydraulic fracturing method is to pump high-pressure water into the coal seam borehole to cause cracks in the coal seam. However, due to the physical properties of water, most of the cracks will only be relatively large during the hydraulic fracturing process, and the cracks The distribution is very uneven. As a result, the local gas permeability of the coal seam is poor, and the gas is pumped after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com