Button cell feeding device

A button battery, battery technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as increased invalid time, battery specification errors, product damage, etc., to reduce manual participation, improve production efficiency, and have broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

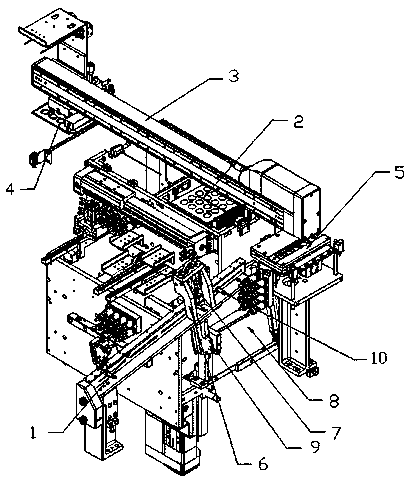

[0024] Such as figure 1 As shown, the present invention discloses a button battery feeding device, which includes a device support, a retrieving assembly for grabbing the tray and completing feeding, and a detection assembly for completing battery detection during the feeding process. A battery chute 1 for auxiliary feeding is fixedly arranged on the equipment support, one end of the battery chute 1 is the feed end, the other end of the battery chute 1 is the discharge end, and the discharge of the material taking assembly The position matches the position of the charging end of the battery chute 1 , and the detection assembly is fixedly arranged on the battery chute 1 .

[0025] The equipment support is provided with a feeding drawer 2, and a plurality of material trays are stacked up and down in the described material loading drawer 2, and each of the material trays is evenly distributed with a plurality of battery storage slots for storing button batteries. The shape and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com