A method for controlling the speed of cooling bed input roller table

A technology of input roller table and control method, which is applied in the direction of cooling bed, rolling mill control device, manufacturing tools, etc., can solve the problem of the lead of the input roller table speed of the cooling bed, and achieve rapid cooling bed, high working efficiency, and dynamic friction coefficient Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described in detail below in conjunction with the description of the drawings and specific embodiments.

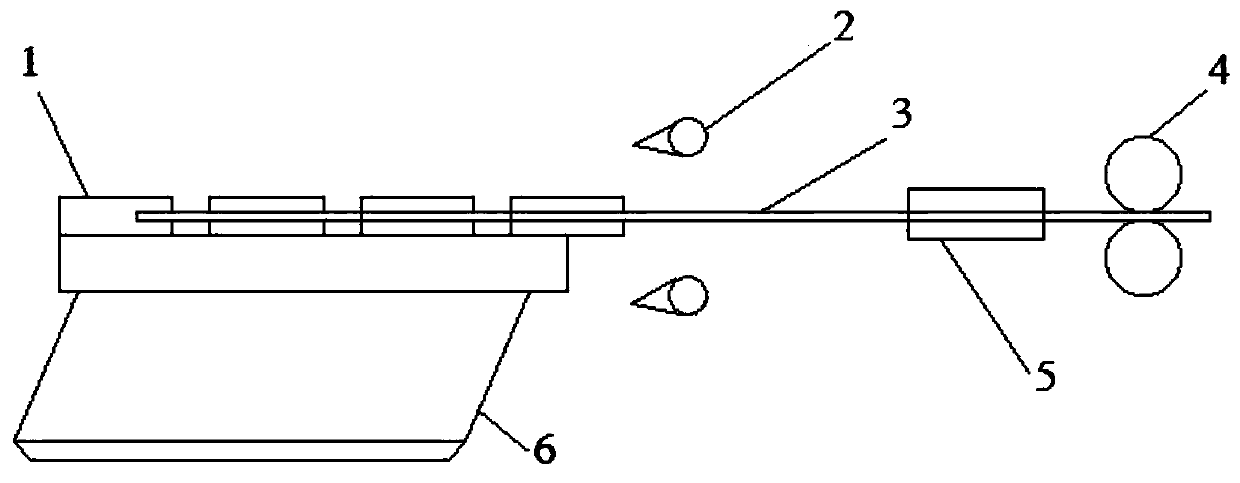

[0019] Such as figure 1 As shown, a method for controlling the speed of the cooling bed input roller table is carried out based on the control system and a plurality of continuous roller tables 1, wherein the plurality of roller tables 1 constitute the cooling bed input roller table, and the control system controls each roller table The rotational speed of the driving device in 1 and the motion state of the monitoring flying shear 2 are specifically implemented according to the following steps:

[0020] Step 1, setting the normal lead coefficient of each roller table 1 speed according to the line speed of the rolling mill 4, and setting the sub-steel lead coefficient of each roller table 1 according to the specification of the steel material 3;

[0021] Step 2, before the flying shear 2 sends out a she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com