Automatic pancake forming equipment

An automatic forming and pancake technology, which is applied in the direction of baking pancakes, baking, oil/fat baking, etc., can solve the problems of unsatisfactory sales, complicated procedures, easy to burn hands, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

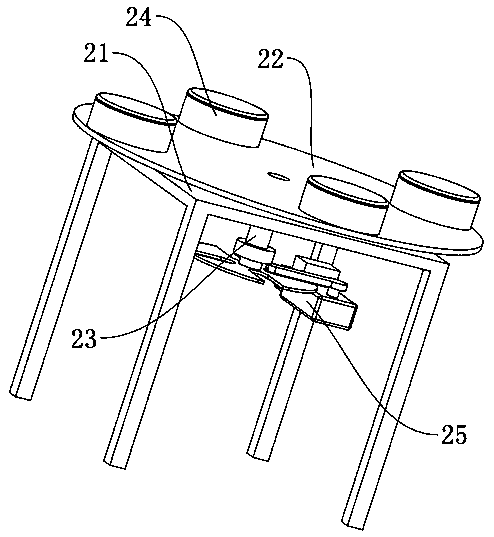

[0035] refer to Figure 1 to Figure 10A kind of pancake automatic forming equipment shown includes a batter feeding device 1, a pancake forming device 2 and a pancake unloading device 3, and the pancake forming device 2 includes a workbench 21, a rotating disk 22 and a The first driving assembly 25 for the rotation of the disk 22, the rotating disk 22 is arranged on the top of the table 21 in a horizontal state, the first driving assembly 25 is arranged at the bottom of the table 21, and the bottom of the rotating disk 22 is arranged There is a rotating shaft 23 for connecting the first driving assembly 25, the rotating shaft 23 passes through the workbench 21 and is connected with the first driving assembly 25 and the rotating shaft 23 is connected with the workbench 21, and the tops of the rotating discs 22 are eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com