Burning and function testing fixture and method for skylight control circuit board

A technology for controlling circuit boards and functional testing, which is applied to electronic circuit testing, program control devices, and electrical measurement. It can solve the problems of reduced production efficiency, low production efficiency, and unfavorable production efficiency of enterprises. The expansion of production scale achieves saving and waiting time, improve economic efficiency, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

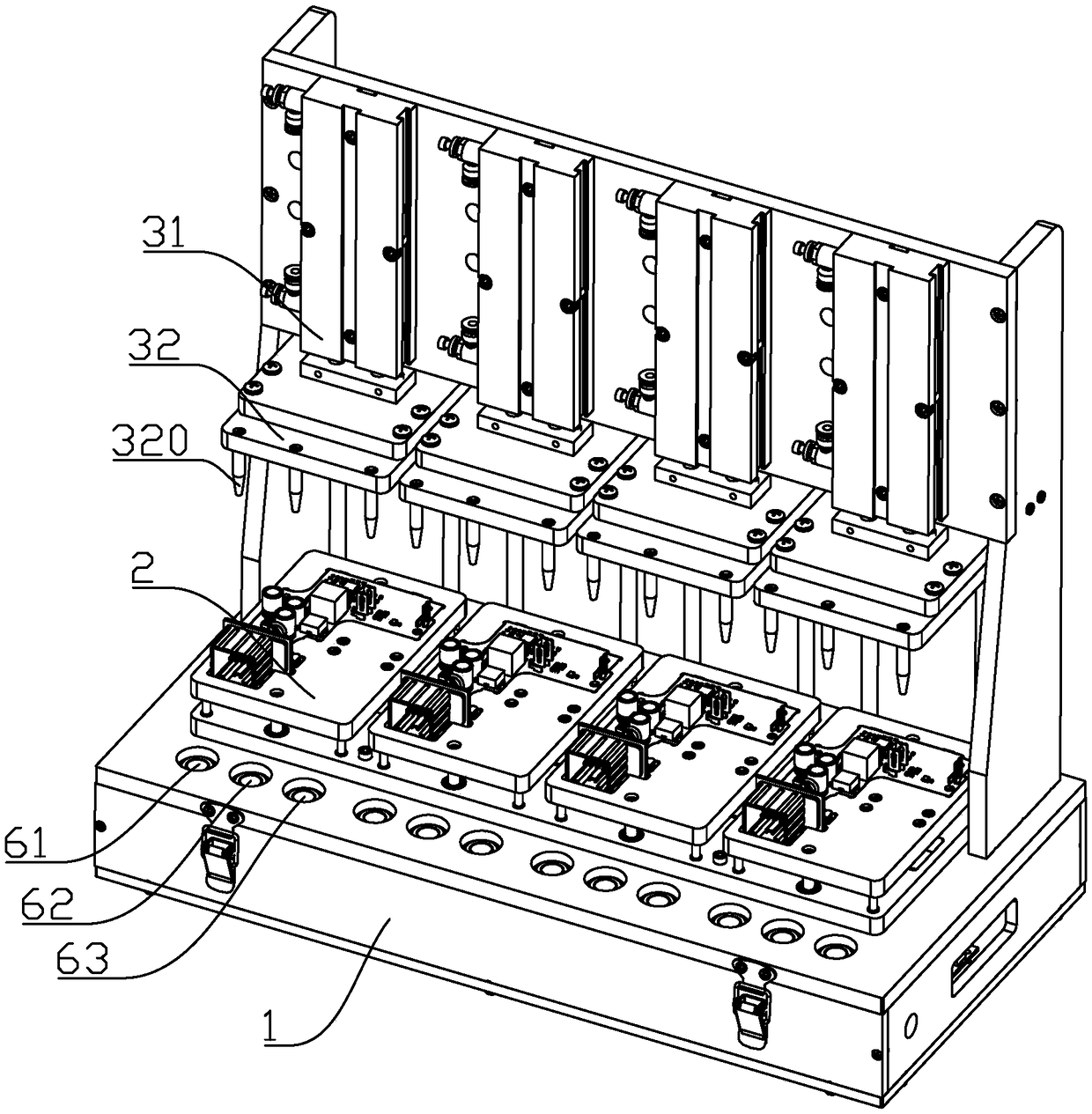

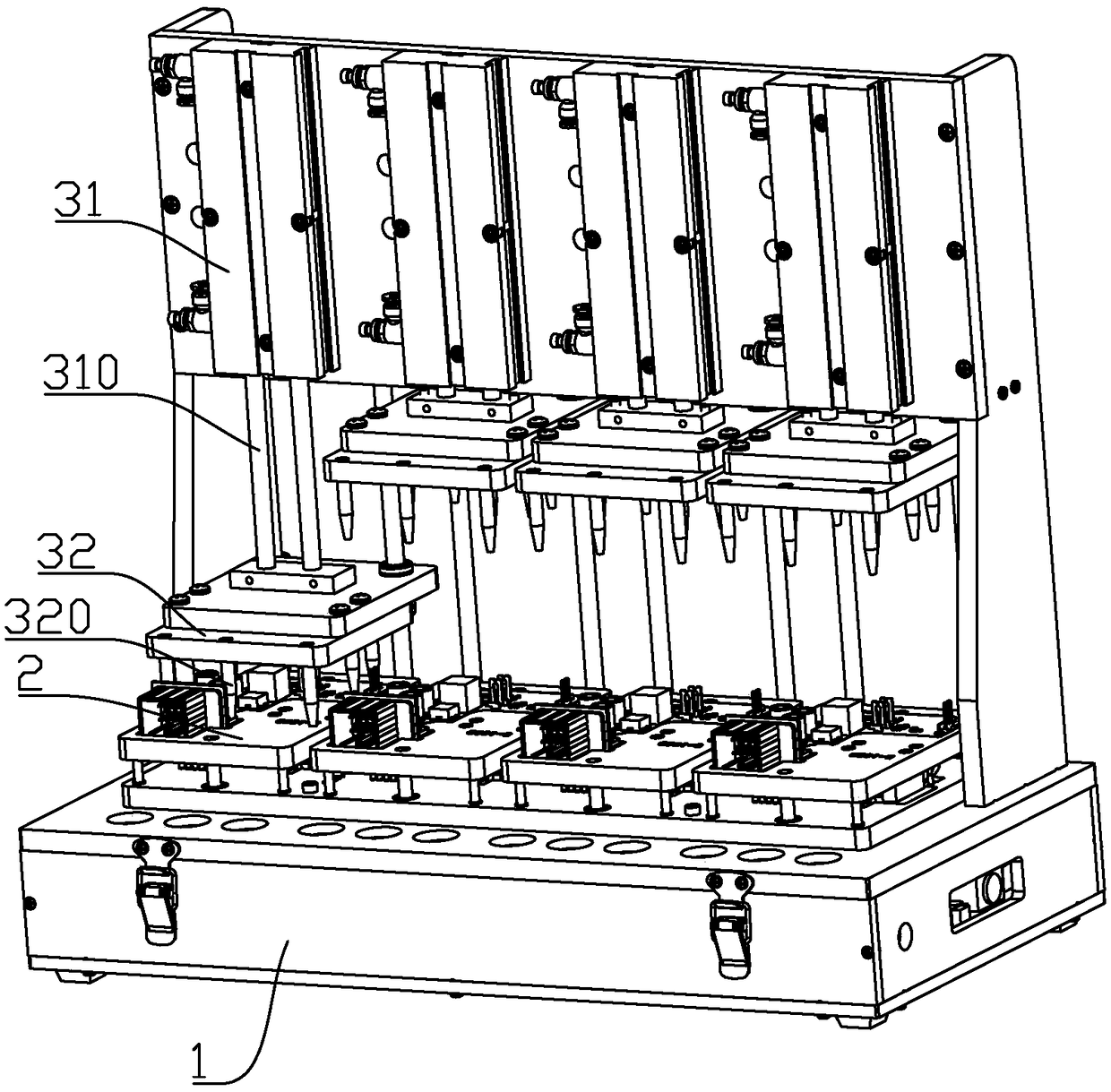

[0044] Such as Figure 1 to Figure 6 As shown, in the embodiment of the present invention, a fixture for programming and function testing of a skylight control circuit board is proposed, which includes a base 1 as a load-bearing structure, and at least two sets of programming and testing mechanisms are arranged side by side on the base 1. In this embodiment, there are four programming and testing mechanisms arranged side by side on the upper surface of the base 1 in turn. Each set of programming and testing mechanisms includes a programming component 2 , a testing component 4 , an automatic lifting component 3 and a programming and testing control module 5 .

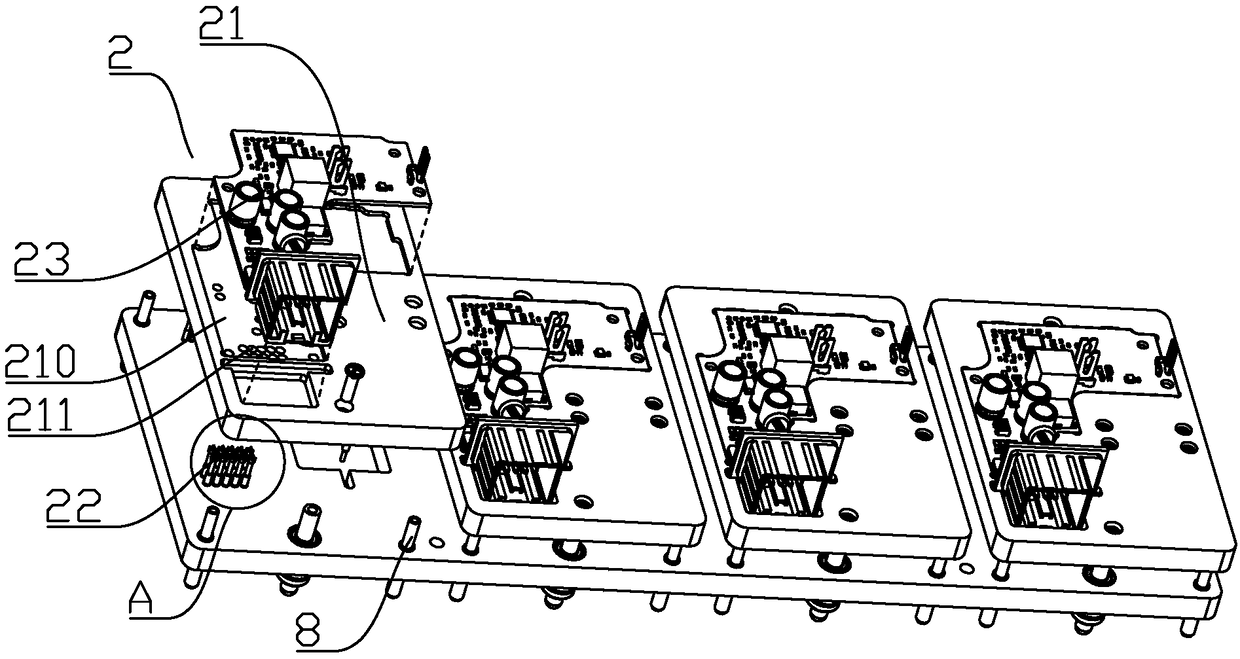

[0045] Wherein, the programming assembly 2 is arranged on the top of the base 1, and is connected with the circuit board 23 to be programmed to burn the circuit board 23; the programming assembly 2 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com