An automatic test system and method for the on-load performance of a power distribution terminal

A technology for automated testing and power distribution terminals, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc. It can solve the problems of interfering with the output port of the on-load power supply, pressure difference, etc., to solve the problem of the on-load power supply output of the measurement point and the actual equipment. The effect of port pressure difference and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

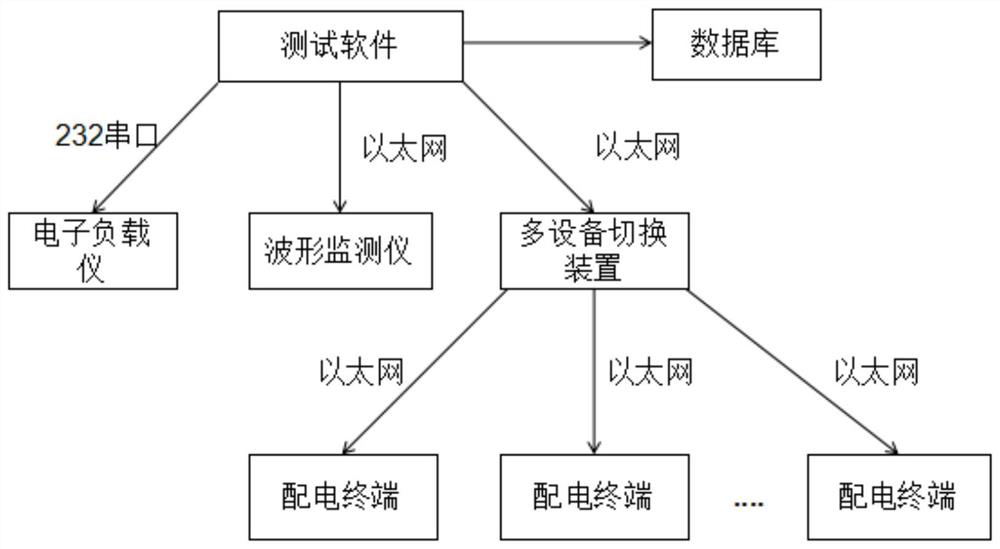

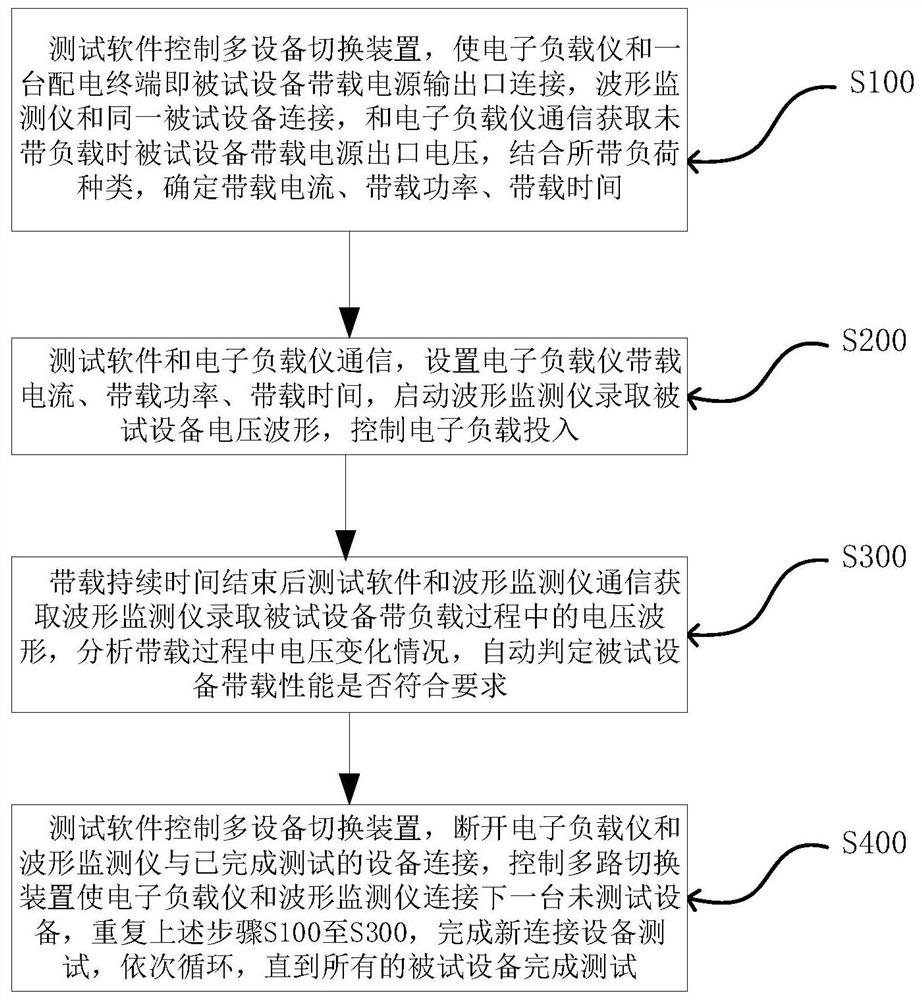

[0034] like figure 1 As shown, the automatic test system for the on-load performance of the power distribution terminal described in this embodiment includes an electronic load meter and a waveform monitor, and also includes a test software, a database, and a multi-device switching device; wherein,

[0035] The multi-device switching device communicates with the power distribution terminal through Ethernet;

[0036] The test software and the database interact to store and read data and configurations;

[0037] The test software and the electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com