A kind of gas chromatography packed column and its preparation method and application

A gas chromatography and packed column technology, applied in the field of analytical chemistry, can solve the problem of low accuracy of dissolved gas in transformer oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

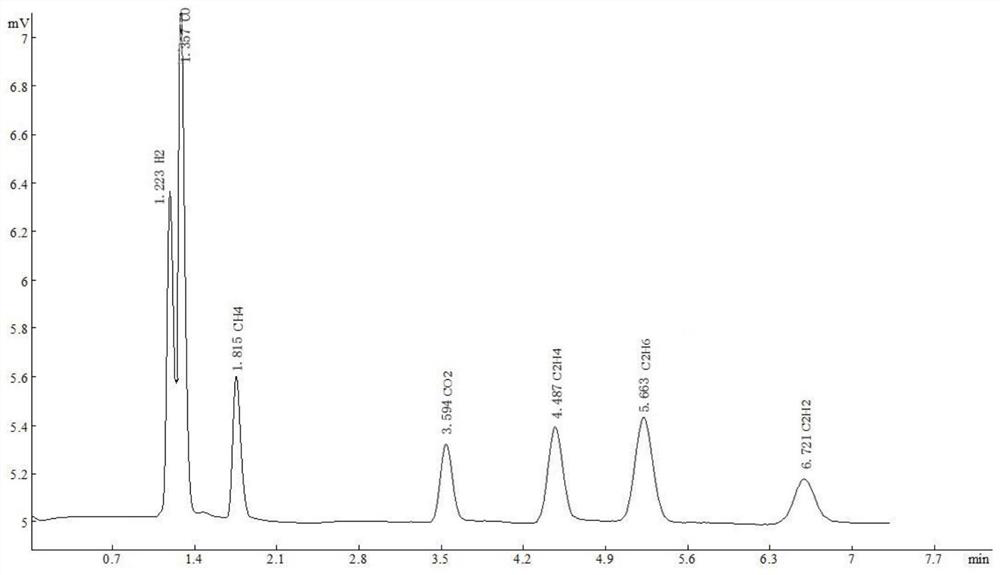

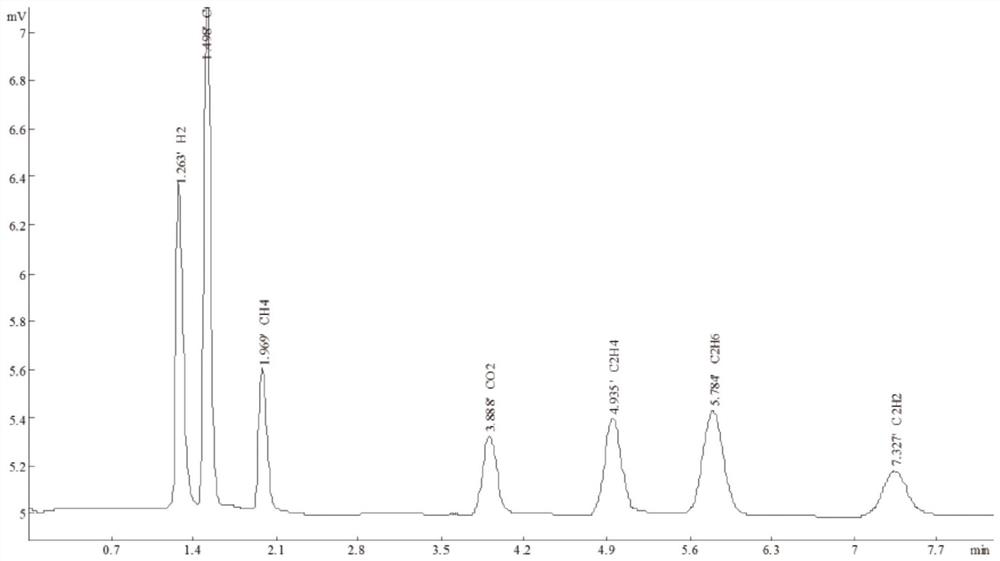

Examples

preparation example Construction

[0045] The present invention also provides a preparation method of a gas chromatographic packed column, the gas chromatographic packed column includes a packed column tube and a packed column stationary phase filled therein, the packed column stationary phase includes a packed column filler; the packed column filler comprises the following steps Preparation method: attapulgite powder is crushed and sieved to obtain attapulgite powder with particle size not less than 200 mesh; binder is added to attapulgite powder and mixed evenly to make attapulgite pellets, 250-350 ℃ drying; the attapulgite balls are sieved and separated to obtain a uniform packed column packing with a particle size of 40 to 140 mesh; further, the preparation method of the gas chromatography packed column is: the packed column tube is cleaned and dried; Plug one end of the column tube with a plug, tap the packed column tube, and add the packed column stationary phase at the same time; after the stationary phas...

Embodiment 1

[0052] A gas chromatographic packed column, comprising a packed column tube and a packed column stationary phase filled therein, the packed column stationary phase includes a packed column filler,

[0053] (1) The packing of the packed column is prepared by using attapulgite with a purity of more than 85%, and the preparation steps are:

[0054] A attapulgite is pulverized and sieved to obtain attapulgite powder with a particle size greater than 200 mesh;

[0055] Add attapulgite powder 0.5% polydiethylaminoethyl methacrylate acetate and a small amount of water to the attapulgite powder, mix evenly, make attapulgite pellets, and dry at 300°C;

[0056]C. After drying, the attapulgite balls are sieved and separated to obtain a uniform packing column packing with a particle size of 40 to 60 mesh;

[0057] (2) The preparation method of gas chromatography packed column is:

[0058] Select a packed column tube made of stainless steel with an inner diameter of 8mm and a length of 8...

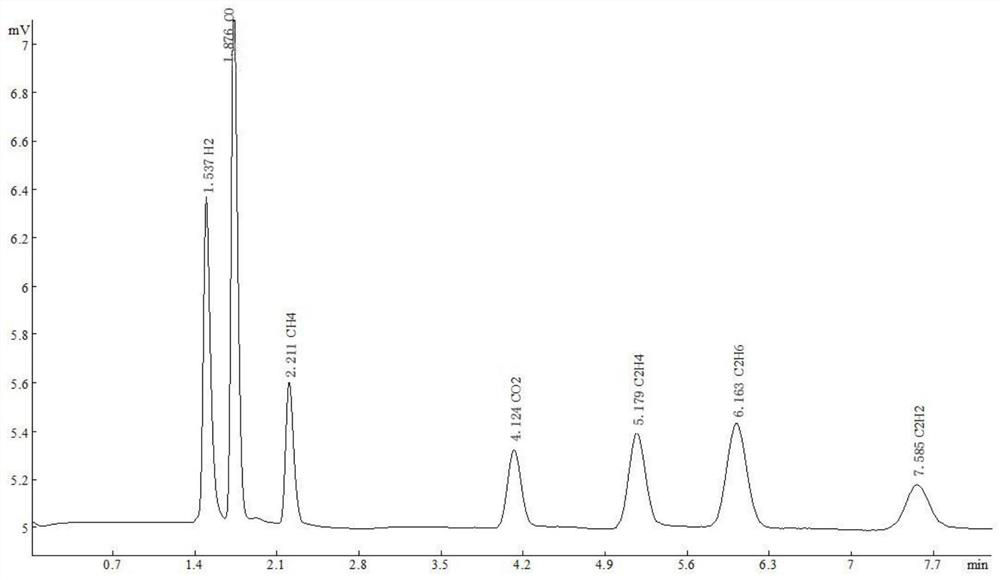

Embodiment 2

[0064] A gas chromatography packed column, comprising a packed column column tube and a packed column stationary phase filled therein, the packed column stationary phase includes packed column filler;

[0065] (1) The packing of the packed column is prepared by using attapulgite with a purity of more than 85%, and the preparation steps are:

[0066] A attapulgite is pulverized and sieved to obtain attapulgite powder with a particle size greater than 200 mesh;

[0067] Add attapulgite mass 1% polydiethylaminoethyl acetate acetate to the attapulgite powder, mix evenly, make attapulgite pellets, and dry at 350°C;

[0068] C. After drying, the attapulgite balls are sieved and separated to obtain a uniform packing column filler with a particle size of 60-80 mesh;

[0069] (2) The preparation method of gas chromatography packed column is:

[0070] Select a stainless steel packed column tube with an inner diameter of 4mm and a length of 6m for cleaning and drying;

[0071] The out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com