Tool used for optical fiber capillary tube film coating

A capillary and tooling technology, applied in the field of optical fiber capillary coating tooling, can solve the problems of bending and breaking optical fibers, affecting the quality of optical fiber capillary products, etc., to meet the coating requirements, improve the coating efficiency, and improve the effect of product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

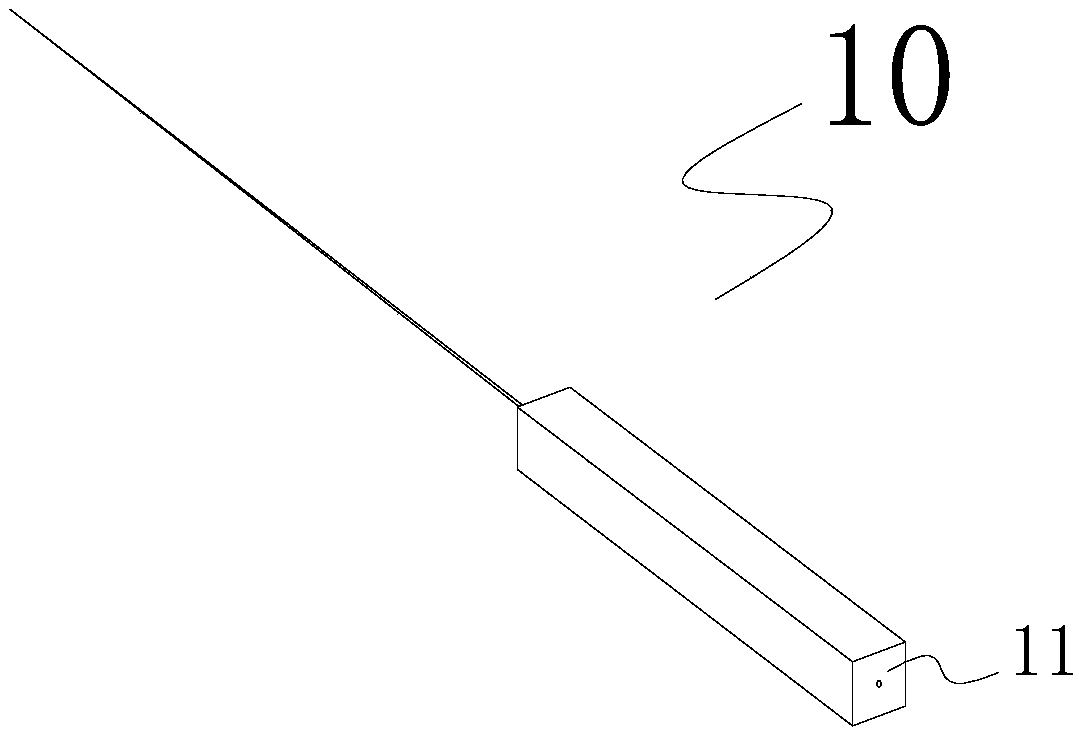

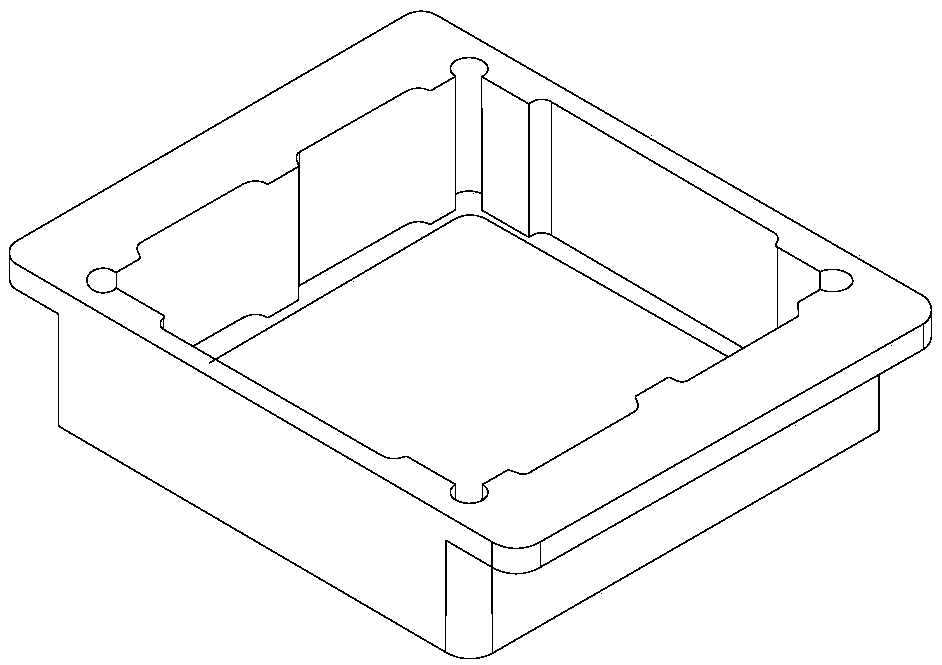

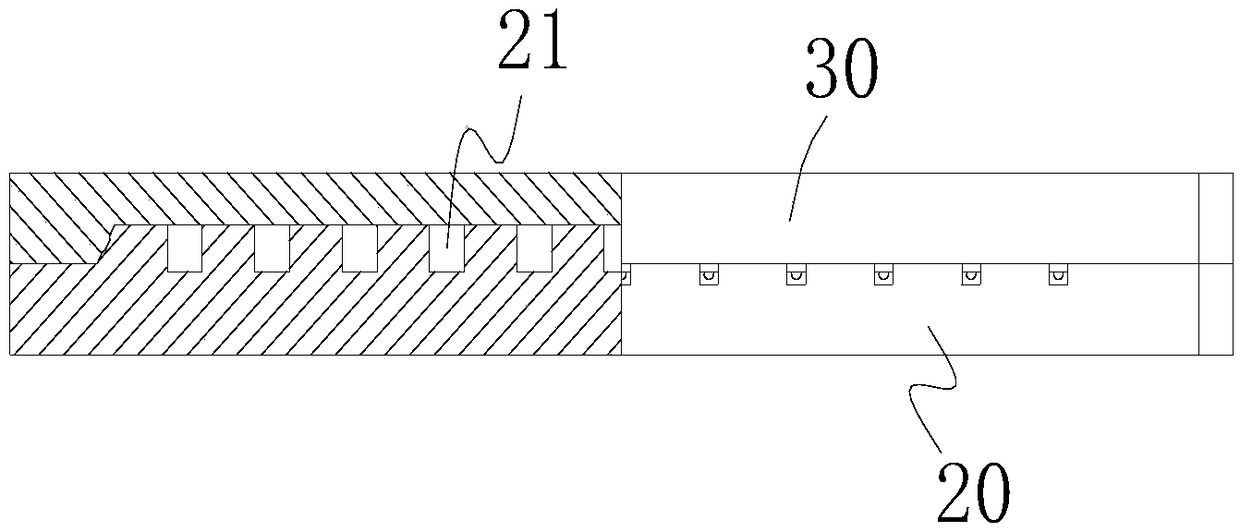

[0031] A tooling for optical fiber capillary coating, including a tooling body, the tooling body is a cuboid structure made of aluminum, and is composed of a base 20 and a cover plate 30 covering the base 20 . The upper surface of the base 20 is provided with several product grooves 21 matching the shape of the optical fiber capillary 10, and the several product grooves 21 are arranged at equal intervals along the length direction of the tooling body. The product groove 21 is provided with an optical fiber limiting end 211 and a capillary limiting end 212 connected with the optical fiber limiting end 211. It is open and communicates with the external medium. When the optical fiber capillary 10 is placed in the product tank 21, its coating surface 11 is equal to or slightly protrudes from the front end of the tooling body. When the coating surface 11 of the optical fiber capillary 10 placed in the product groove 21 is equal to the front end surface of the tooling body, rounded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com