Line-lamp lens pasting machine and system

A line light and lens technology, applied in the direction of conveyors, conveyor objects, vibrating conveyors, etc., can solve the problems of reduced production efficiency, high labor costs, and low enterprise benefits, so as to improve production efficiency, promote social development, and achieve high efficiency. The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

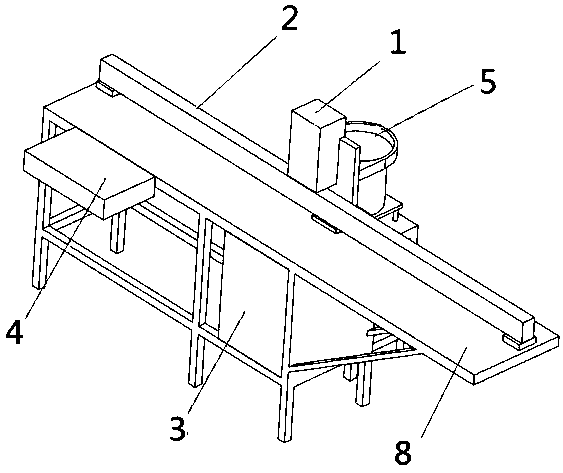

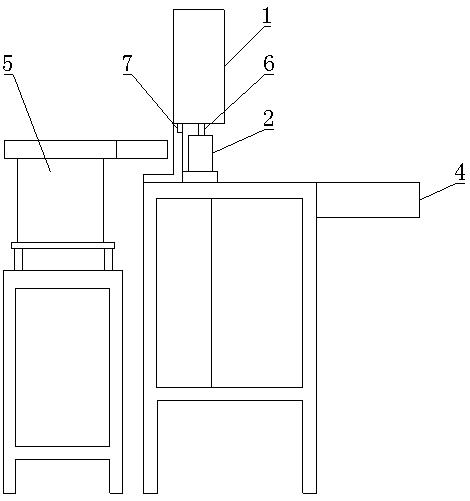

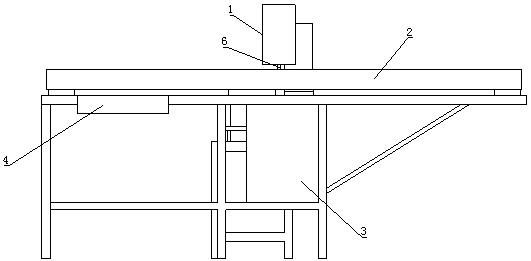

[0040] like Figure 1-8 as shown, figure 1 It is a structural schematic diagram of a line lamp lens sticking machine proposed by the present invention.

[0041] refer to Figure 1-8 , a line light sticking lens machine proposed by the present invention includes a lens sticking device 1, a line light conveying device 2, an electrical control box 3, a system control cabinet 4, a vibrating plate feeding device 5 and a support frame 8; wherein the lens sticking device 1 The lower end surface is provided with a first suction nozzle 6 and a second suction nozzle 7; the first suction nozzle 6 is close to the linear lamp conveying device 2; the second suction nozzle 7 is close to the vibrating plate conveying device 5;

[0042] Next to the support frame 8, the vibrating plate feeding device 5 is placed side by side; the electric control box 3 is installed on the support frame 8; the upper end surface of the support frame 8 is connected with the linear lamp conveying device 2; 8 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com