Charging station and charging station cooling control method

A charging station and charging cabinet technology, which is applied in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve the problems of difficulty in quickly reducing local high temperature of equipment and difficulty in heating, so as to improve heat dissipation and cooling efficiency, prolong product life, reduce The effect of stopping or frying small products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

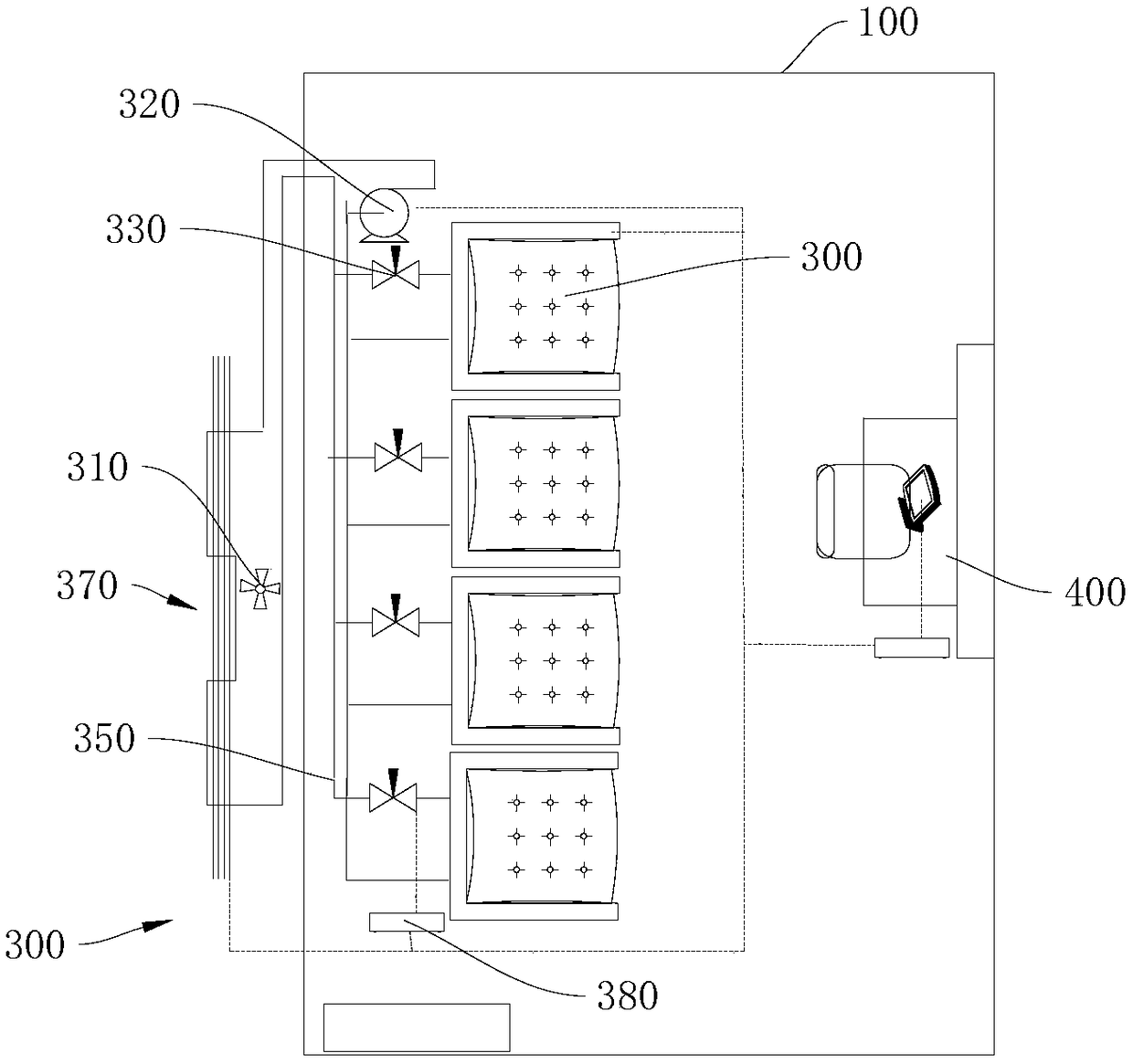

[0042] see figure 1 , the present embodiment provides a charging station 10, which is used for charging a car. When the charging station 10 is in use, a large amount of heat will be generated. If the heat cannot be dissipated in time, it will cause damage to the charging station 10 . The charging station 10 can improve heat dissipation and cooling efficiency, ensure the stable operation of the charging station 10, reduce product downtime or failure caused by local overheating, and prolong the product life.

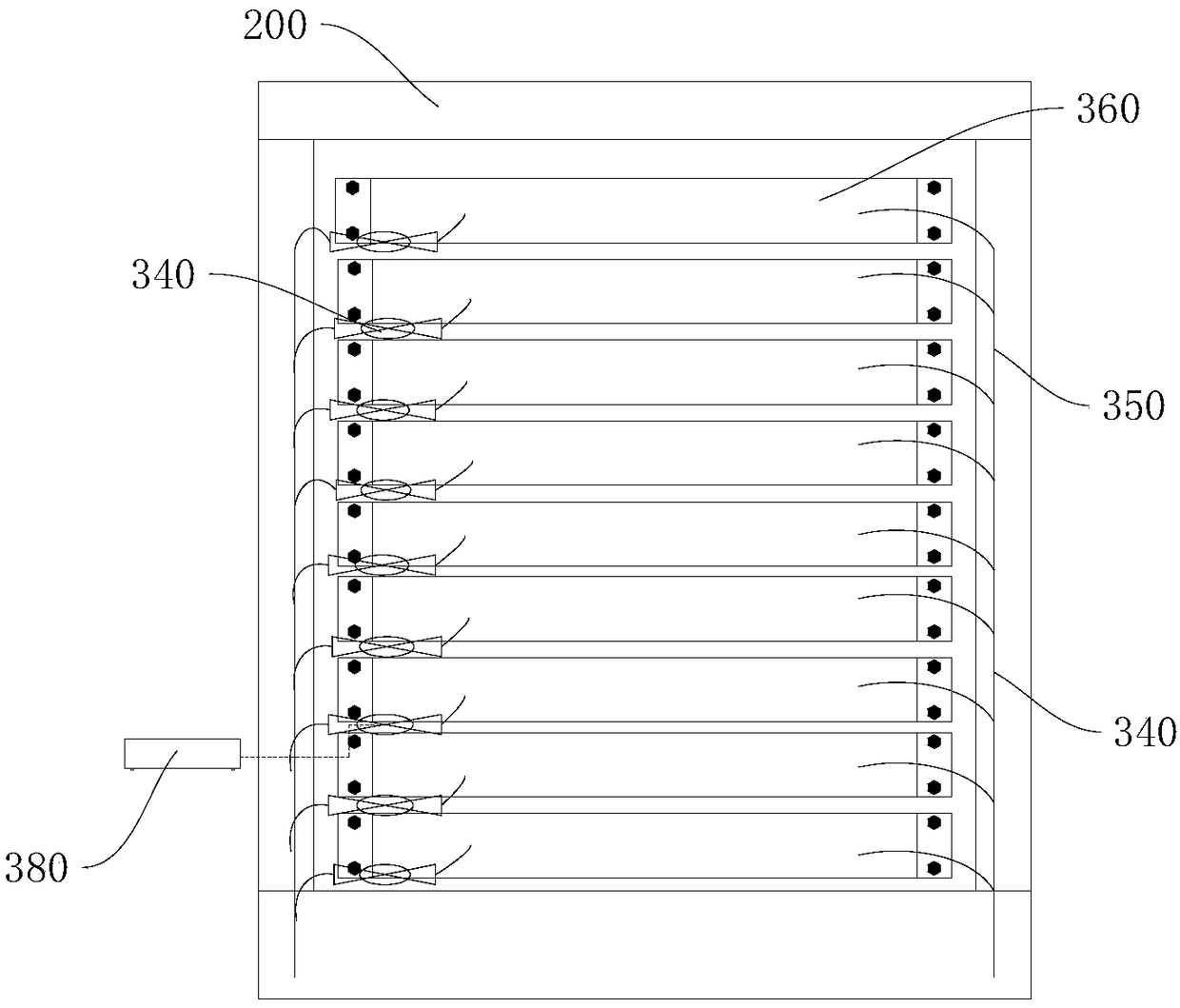

[0043] Please refer to figure 1 with figure 2 , the charging station 10 includes a station body 100 , a control system 400 , a liquid cooling circulation system 300 and a charging cabinet 200 . Wherein, the charging cabinet 200 is arranged inside the station body 100, and the charging cabinet 200 is used for charging the car, and a large amount of heat will be generated when the charging cabinet 200 is preparing to charge or charging. The liquid cooling circulation sy...

no. 2 example

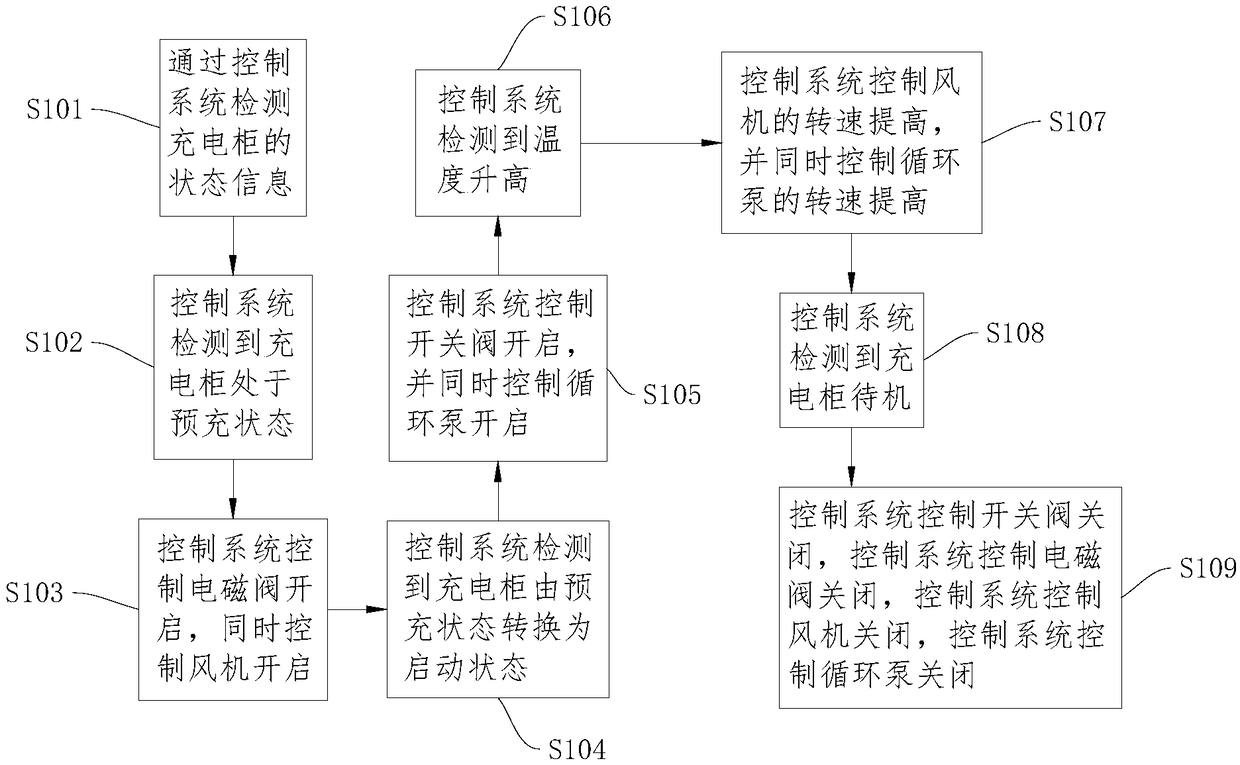

[0065] Please refer to figure 1 , figure 2 with image 3 , this embodiment provides a charging station cooling control method, which is applied to the charging station 10 provided in the first embodiment, to improve the heat dissipation and cooling efficiency, ensure the stable operation of the charging station 10, and reduce the damage caused by local overheating. The product is shut down or fried to extend the life of the product.

[0066] Among them, the charging station cooling control method includes:

[0067] S101 . Detect the state information of the charging cabinet 200 through the control system 400 .

[0068] S102. The control system 400 detects that the charging cabinet 200 is in a pre-charging state.

[0069] That is, at this time, the charging cabinet 200 is preparing to charge the car. At this time, the charging cabinet 200 increases the output voltage until the output voltage reaches the preset voltage.

[0070] S103. The control system 400 controls the sole...

no. 3 example

[0084] This embodiment provides a charging system (not shown in the figure), which adopts the charging station 10 provided in the first embodiment. The charging system can improve the heat dissipation and cooling efficiency, ensure the stable operation of the charging system, reduce product shutdown or explosion caused by local overheating, and prolong the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com