Tooth surface broaching machine capable of being automatically machined into whole set connecting rod workpiece

An automatic processing and connecting rod technology, applied in broaching machine, broaching machine device, metal processing equipment, etc., can solve the problem that the workpiece cannot be automatically loaded and locked, and the first connecting rod workpiece and the second connecting rod workpiece cannot be processed, etc. problem, to achieve the effect of consistent accuracy, uniform force, and avoidance of swing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

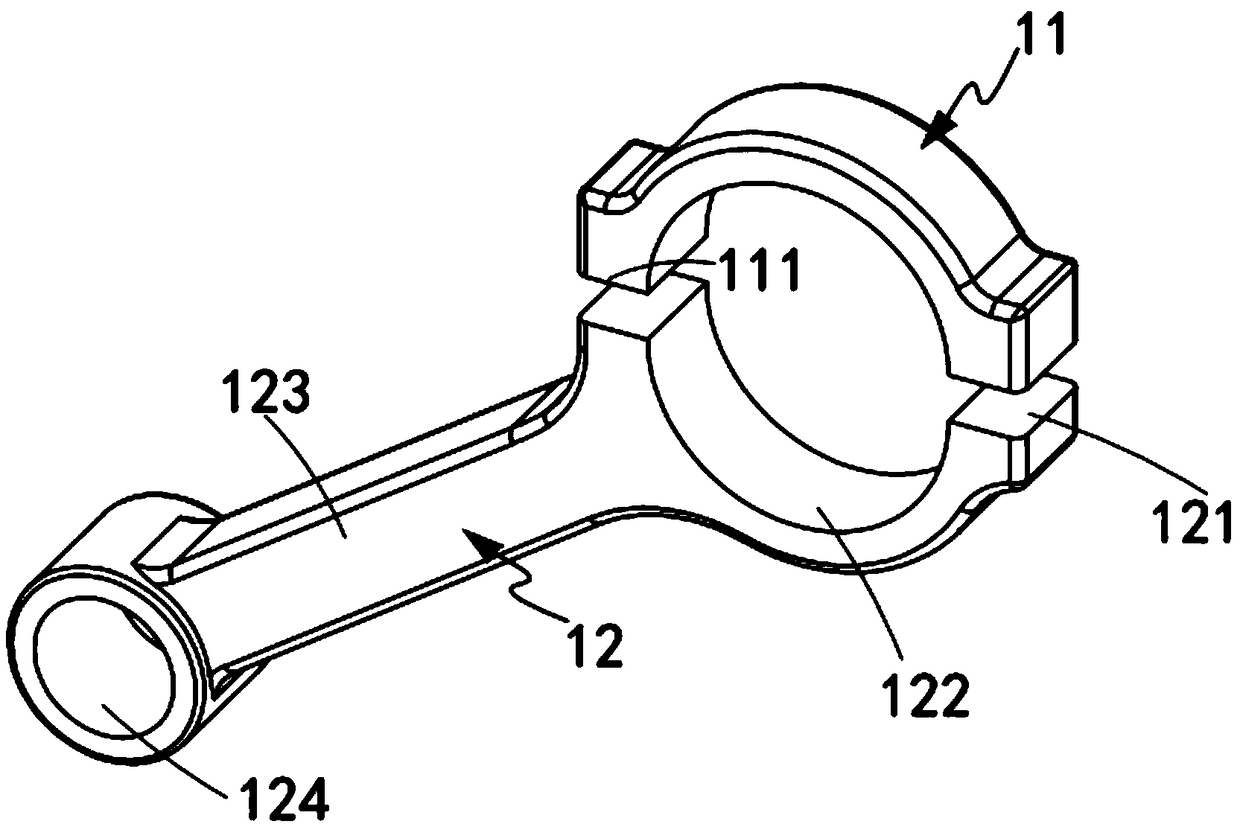

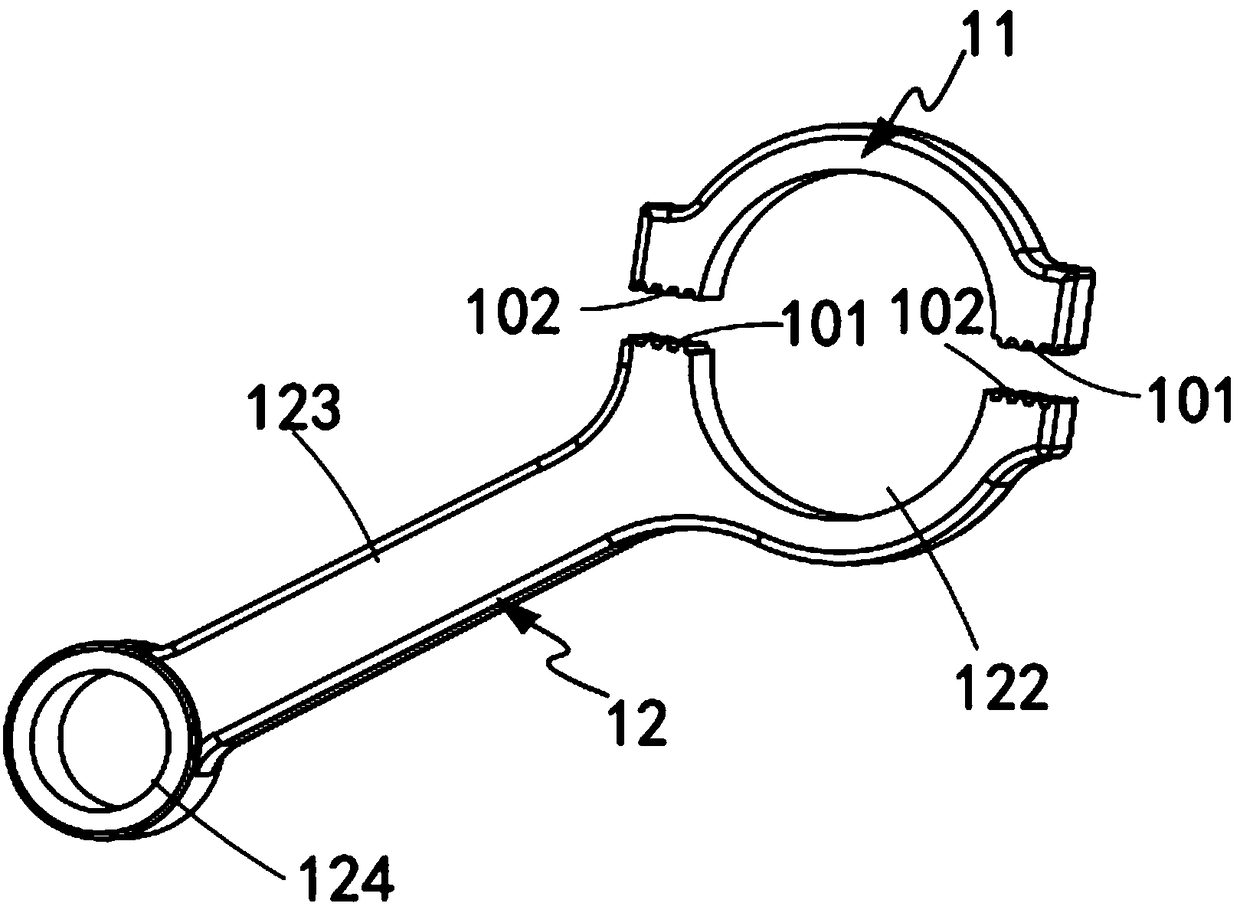

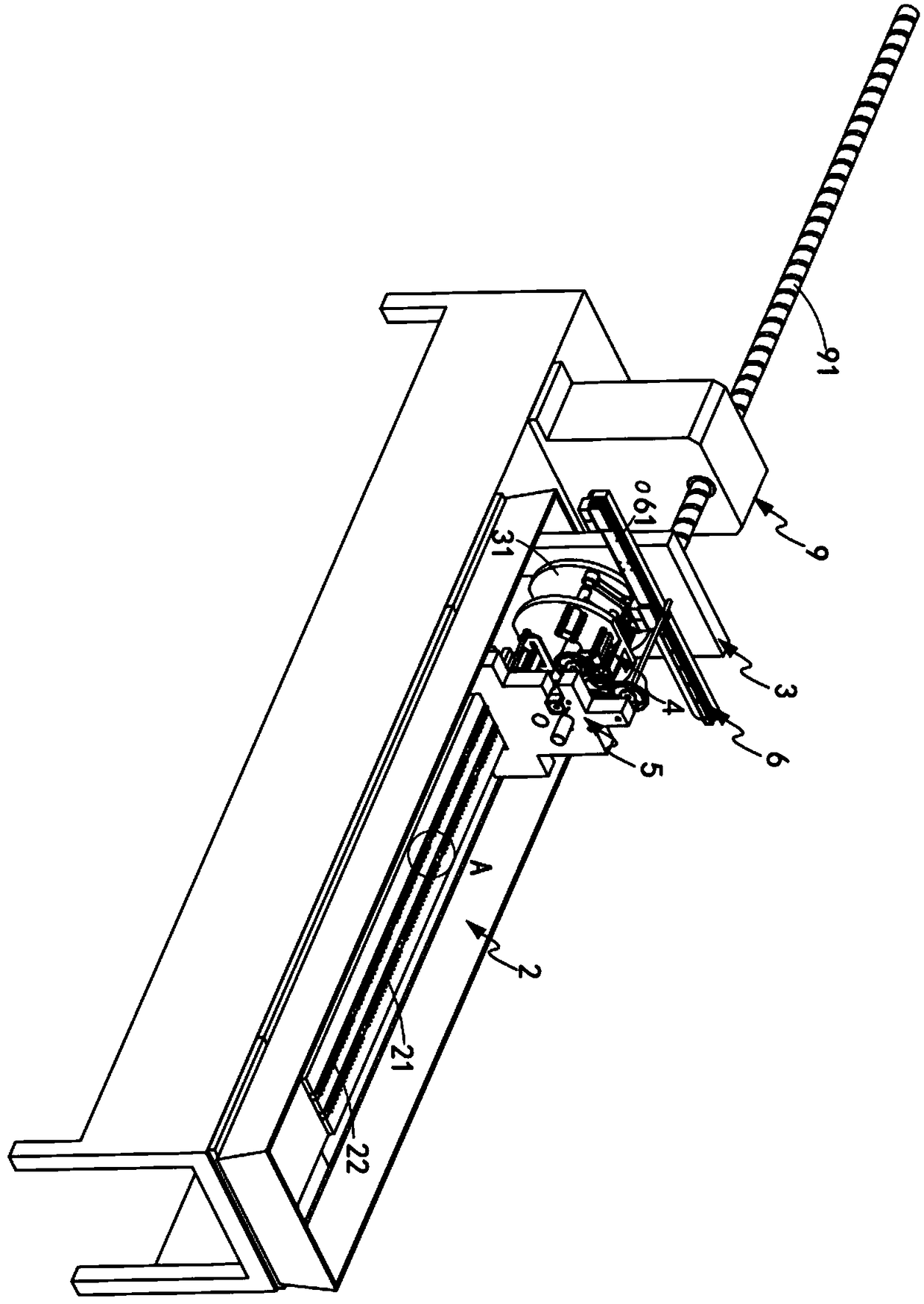

[0070] Such as figure 1 , figure 2 , image 3 , Figure 15 As shown, a broaching machine for automatically processing the tooth surface of a complete set of connecting rod workpieces, which performs extrusion and friction processing on the complete set of first connecting rod workpieces 11 and second connecting rod workpieces 12, so that the teeth on the first connecting rod workpiece 11 The first processed end surface 111 and the second processed end surface 121 on the second connecting rod workpiece 12 both form the first tooth surface 101 and the second tooth surface 102, the first connecting rod workpiece 11 is arranged in a semicircular shape, and the The second connecting rod workpiece 12 includes a semicircular ring part 122, a handle part 123 and a ring part 124. The workpiece 11 is correspondingly matched, and the broaching machine includes:

[0071] A processing platform 2, a first rack 21 and a second rack 22 are arranged in parallel in the length direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com